The Machland Dam protects the people, homes and historic landmarks of the Machland floodplain from the destructive effects of Danube flooding. With nearly 130 fully automated pumps, sluice gates and power supply stations connected in a redundant ring network stretching over 36 kilometers, the system is anything but static and passive. Indeed, it represents one of the largest interconnected automation solutions in Central Europe. The project was carried out by Electro & Electronic Landsteiner, an automation company with extensive environmental engineering experience, using B&R systems.

Rushing rivers where there should be streets and town squares. Boats and helicopters struggling to bring trapped residents to safety. Unfortunately, these are all too familiar sights in Austria's Machland region. The Danube river floodplain between the towns of Mauthausen and Grein owes its famed fertility in large part to frequent flooding. Plans for more comprehensive flood control measures existed long before the devastating flood of 2002, in the wake of which entire villages were razed and relocated to higher grounds.

The original plans had been drawn up following the flood of 1991 – but had to be fundamentally revised a decade later in light of the shocking experiences of the 2002 flood. Completed in 2012, the Machland Dam boasts a total length of over 36 kilometers, making it the largest flood control project Europe has ever built. At a cost of nearly €182 million, the historic structure now protects around 22,000 people from future calamities.

Fully automated and highly available

The Machland Dam is anything but static and passive. In addition to around 29 kilometers of earthen levees, 7 kilometers of protective walls (some of them mobile) and a flood channel nearly 9 kilometers long, there are also 32 retaining structures that can be closed on demand to fill the remaining gaps. The system's 72 pump stations contain 248 pumps that are capable of moving a total of 50,000 liters of water per second from the surrounding area into the confines of the levees. The structure is supplied by 24 stations able to deliver up to 8.8 megawatts of power. Normally operated as transformer stations, they are also equipped with diesel generators for the event of a power outage.

"In an emergency, these systems need to kick in fully automatically with absolute reliability," says Anton Wahlmüller, managing director of the dam's operating company. "That's why we have standardized our pumps and designed in an exceptional level of safety." Demanding requirements were also placed on the system's control technology.

Monumental automation project

Like all publicly funded projects, the contracts for the Machland Dam were put to tender EU-wide. The instrumentation and controls contract for all eight dam segments was awarded to Electro & Electronic Landsteiner as part of joint bid from a group that also included mechanical engineering and steel hydraulics construction companies. A family business founded in Amstetten, Austria, in 1966, Landsteiner manufactures power distribution and control systems as well as type-tested switchgear and controlgear assemblies.

The company has decades of experience equipping industrial and environmental systems with electronics, instrumentation and controls, as well as process control technology and HMI systems. Using the most advanced technology available, they pioneer sophisticated solutions with maximum operational stability. "Although we have plenty of experience in this field, the Machland Dam was a unique challenge due to its shear size," recalls Franz Reisinger, who has been in charge of machine and process control at Landsteiner for 15 years. "With the segments of the system spanning nearly 40 kilometers, it is the largest single automation project in our company's 50-year history."

Redundant, distributed intelligence

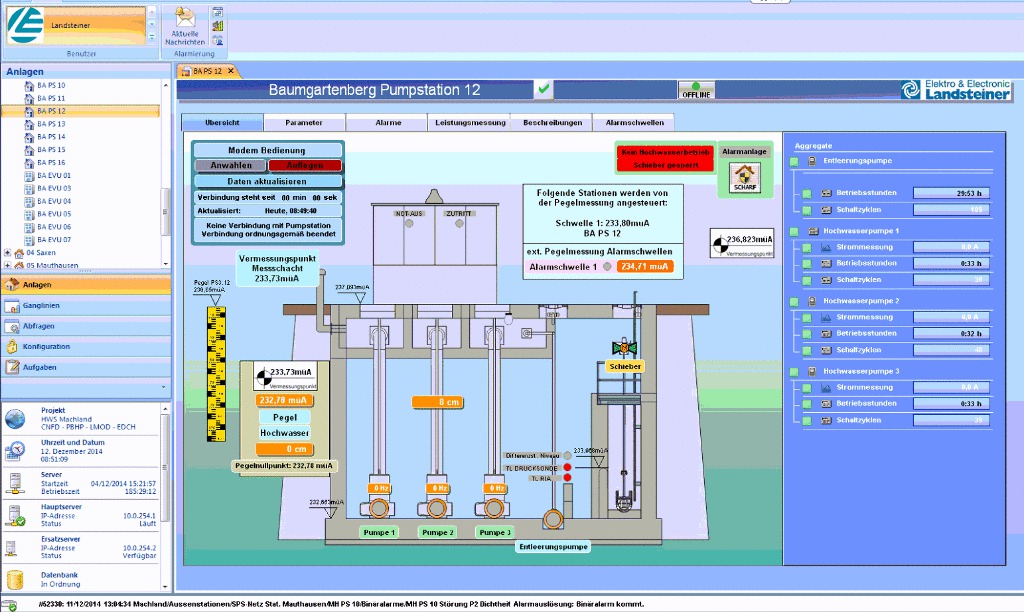

The central control room is found at the headquarters of the dam's operating company in the district capital of Perg. From here, each segment of the system has a secure, redundant VPN connection to the telecommunications network. In the event that both lines should fail, they can also switch to a wireless connection. The individual stations within each segment are interconnected via fiber optics.

The controllers along the length of the dam communicate with matching controllers in the central control room. They handle data exchange between the individual segments and the two redundant servers of the master computer. All in all, Machland's active flood control solution is a single system comprising nearly 130 controllers connected in a resilient redundant ring network.

Proven distributed control technology

The local control stations have their own challenges to master. Over 100 I/O channels monitor and compare measurements from redundant sensors. These sensors measure the water level of the Danube and its tributaries, positions of sluice gates, status of pumps as well as alarm signals and the fuel reserves of the emergency generators. They also control various displays. A powerful level control loop also runs on the local controllers. The power measuring instruments at each station and the drives for the pumps and sluice gates are connected via PROFIBUS, while communication to the supervisory level takes place over TCP/IP.

The control hardware is mounted directly in each sluice gate, pump or power supply station – some of these have their own buildings, while others require outdoor control cabinets. The key selection criteria for the system components included a compact, robust design, and – considering the potential need to operate them with an emergency generator – low power consumption. The automation specialists at B&R provided PLC and I/O modules from their compact X20 series for distributed control, as well as Power Panel 45 terminals with 5.7" touch screen displays for local monitoring and operation.

Advanced technology and the support to match

For many years, Landsteiner has relied exclusively on B&R for its automation systems and components. "The versatile X20 system is not only very compact and extremely robust, it also has a nearly unbeatable price/performance ratio," explains Reisinger. "Their Automation Studio environment brings together all the tools we need to develop and test the entire solution – controls, HMI, communication, everything – as a single, integrated unit."

The dam's operating company, MDB Machland-Damm Betriebs GmbH, emphasizes other qualities of the B&R solution as well. "We need this system to operate reliably for many decades," says Wahlmüller, "so it's important that we can rely on the long-term availability of B&R's devices and components, as well as their famous local support."

Future-proof automation

To ensure that there are no unpleasant surprises when maintaining or expanding an application, B&R offers an unprecedented degree of compatibility. "You don't need to worry about what CPU the program is going to run on while you're developing," Reisinger is happy to report. "And the question of what channels will be used for communication doesn't need to be answered during programming – that's simply a matter of configuring the respective bus controller." In cooperation with B&R, Landsteiner created a single program containing all the technical functions for the pump and sluice gate stations. The controllers simply retrieve the station-specific parameters they need automatically.

New or modified functions are programmed and tested at Landsteiner and then sent to the flood control system via remote data transmission. The ability to develop self-contained program modules allows modifications to be integrated without any disruptions. They can added to the existing system without having to revalidate all the other components.

All the software for the Machland Dam, including all control, HMI and communication systems, is developed and tested in Amstetten using the Automation Studio engineering environment and delivered to its destination using remote data transmission. The ability to develop self-contained program modules and add them to the existing system allows modifications to be integrated without any disruptions. Since the software can easily be transferred to any other B&R PLC, the Machland Dam is ensured suitable replacement hardware across many generations of controllers.

"We need this system to operate reliably for many decades, so it's important that we can rely on the long-term availability of B&R's devices and components, as well as their famous support." Anton Wahlmüller, Managing Director, MDB Machland-Damm Betriebs GmbH

"The versatile X20 system is not only very compact and extremely robust, it also has an unbeatable price/performance ratio." Franz Reisinger, Head of Machine and Process Control, Landsteiner

Practice-proven

"When the Danube's tributaries start to rise, so does our blood pressure," reports Wahlmüller. "But when severe flooding occurred again in 2013, the world's largest interconnected X20 system provided an impressive demonstration that it was more than up to the task."