Descripción

Robotics technology expands the B&R drive solution with functionalities that enable multiple axes to be combined into groups, serial and parallel kinematics to be configured, and path-controlled movements to be executed.

Path-controlled movements are the basis for precise and complex robotics applications. In addition to a very wide range of interpolation methods, many technology functions are also supported.

The use of PLCopen-compliant mapp Motion components allows them to be seamlessly integrated into the robotics application.

- Overview of how an axis group works

- Robot configuration in Automation Studio

- Robot commissioning and diagnostics

- Programming with PLCopen-compliant mapp Motion components

- Robotics technology

- Basic principles of path-controlled movements

- Creating robot programs

- Communication between a robot program and the control system

- Use of coordinate systems and tools

- Configuration of workspace monitoring

Documentos proporcionados

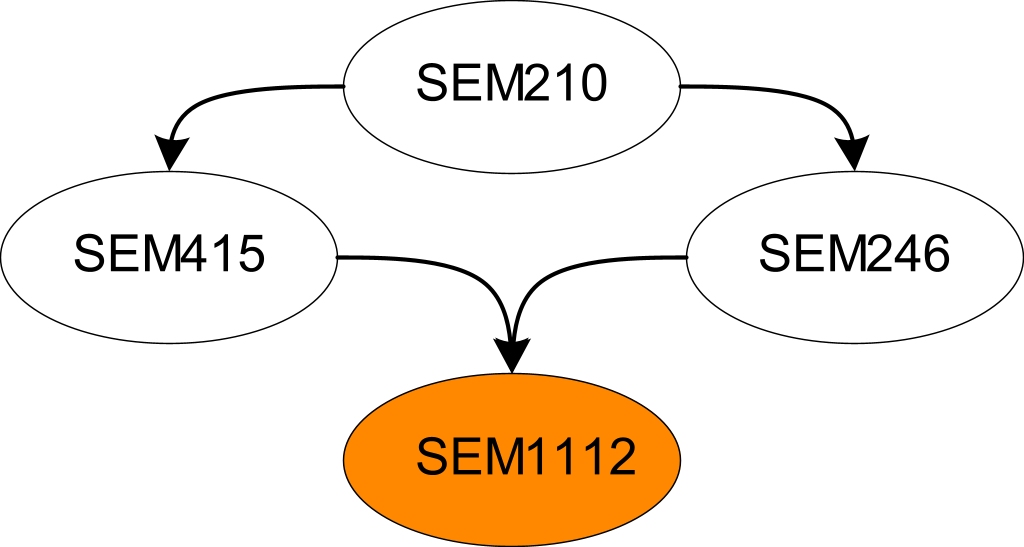

TM1112 – Robot technology: mapp Robotics

TM1112 - Robot technology: mapp Robotics

Learning objectives and content

- Overview of how an axis group works

- Robot configuration in Automation Studio

- Robot commissioning and diagnostics

- Programming with PLCopen-compliant mapp Motion components

- Robotics technology

- The basics of path-controlled movements

- Creating robot programs

- Communication between a robot program and the control system

- Use of coordinate systems and tools

- Configuration of workspace monitoring

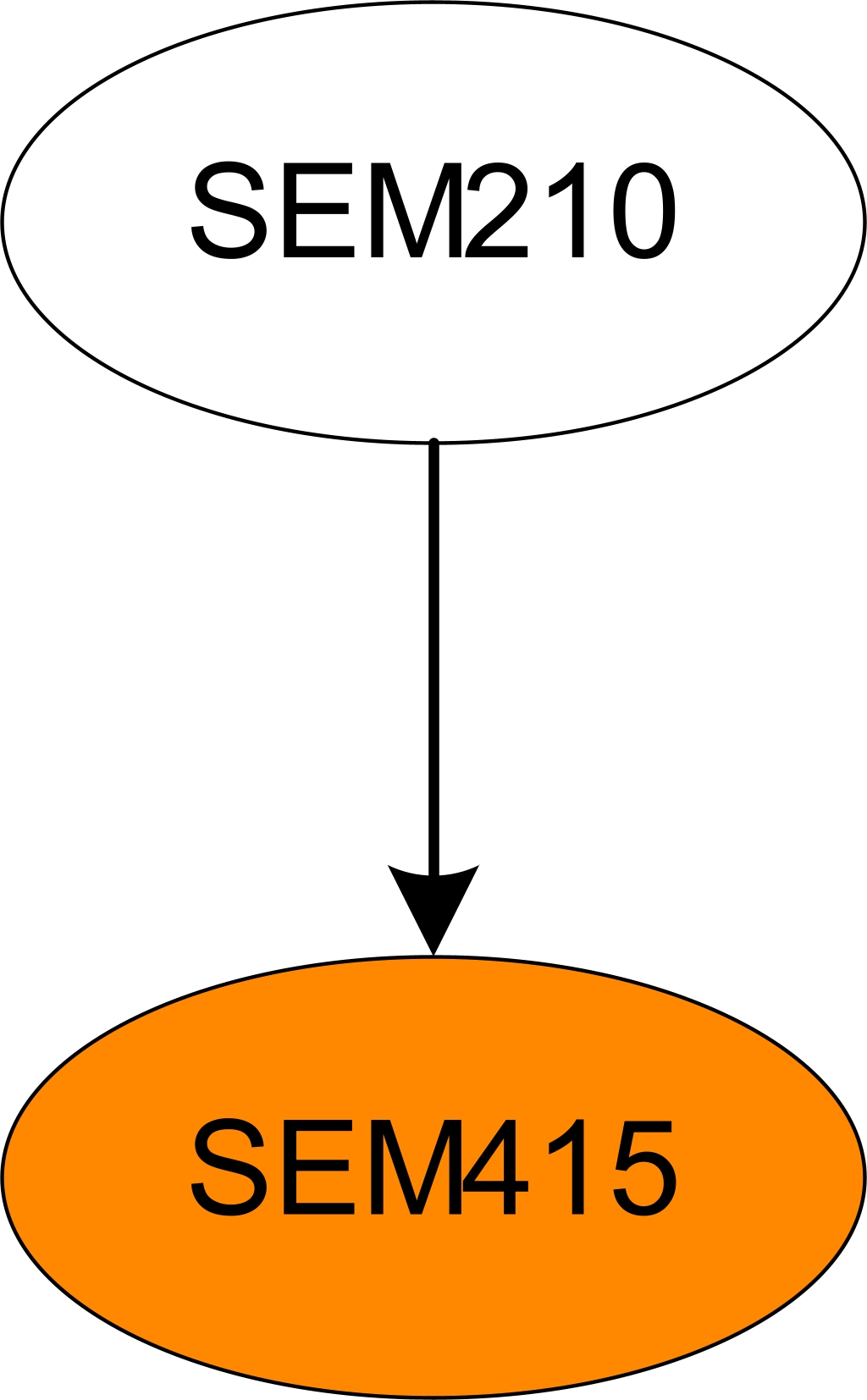

Requisitos previos

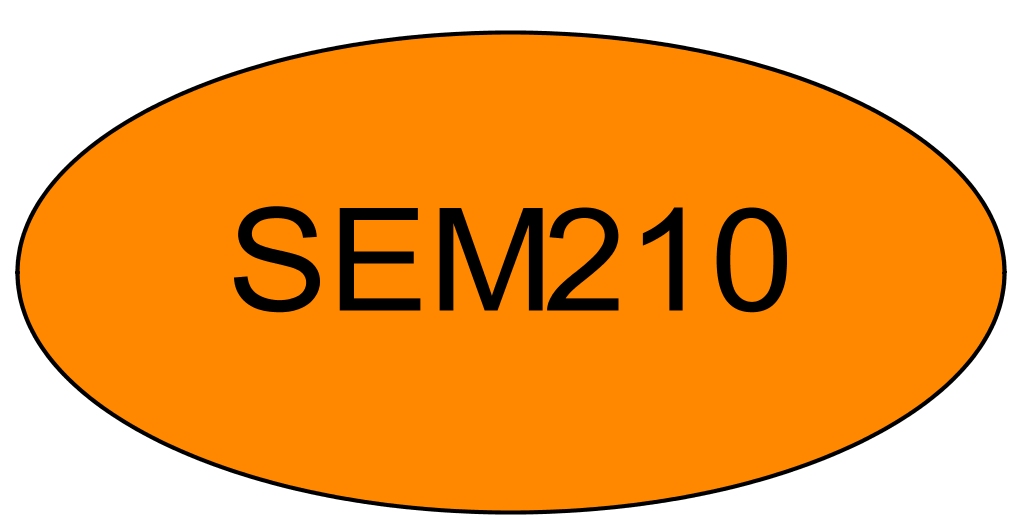

SEM210 – Automation Studio Training: Basics

Automation Studio is used to configure and program all B&R controller components. Core topics such as getting an overview of all product groups, initial commissioning of a controller, understanding the functions of the runtime environment and using the options for integrated configuration and diagnostics will be shown.

- B&R company presentation

- B&R philosophy and products

- Working with Automation Studio

- Using the integrated help system

- Establishing an online connection to the controller

- Initial installation of a controller

- Developing the hardware configuration

- Working with text and table editors

- Functions and options offered by Automation RuntimeAutomation Runtime is the operating system that runs on all B&R controllers.

- Automation Runtime configuration options

- Runtime and boot behavior of the controller

- Using the integrated diagnostic options

- Overview of available programming languages

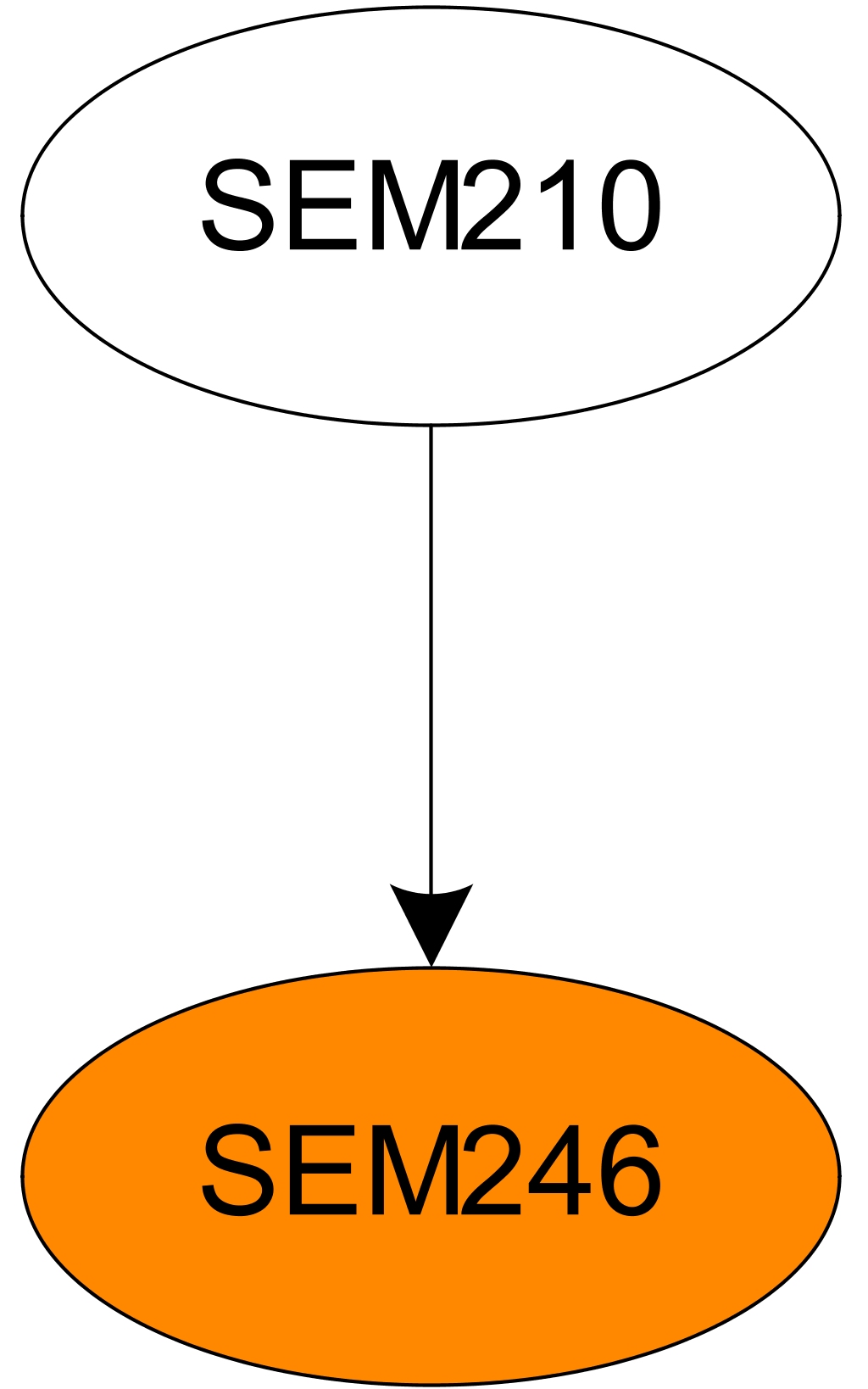

SEM246 – Automation Studio Workshop:IEC 61131-3 Text-based Programming with ST

The IEC 61131-3 programming languages provide standardized access to PLC programming. Simple yet powerful language constructs facilitate the programming of a variety of control systems.

- Overview of programming languages based on IEC 61131-3IEC 61131-3 is the only valid international standard for programming languages used on PLCs. In addition to Sequential Function Chart, it defines other programming languages such as Ladder Diagram, Instruction List, Structured Text and Function Block Diagram.

- Differences between textual and graphical programming languages

- Working with Structured Text (ST)

- Basic constructs

- Decisions

- Loops

- Working with arrays

- Step switching mechanisms

- Calling function blocks

- Calling actions

- Creating simple programs independently

- Working with another programming language (optional)

SEM415 – Training: Integrated motion control: mapp Axis

The B&R drive solution provides flexible, high-performance tools for controlling drives. These solutions are configured, put into service and diagnosed using Automation Studio.

A variety of drive components and functions are available.

The use of PLCopen-compliant mapp Motion components allows them to be seamlessly integrated into the machine application.

- The concept behind the B&R drive solution

- Wiring and diagnostics

- Guidance in Automation Help

- Testing environments and commissioning

- Control concepts and autotuning

- Simulation options for a drive

- Preparation of information for support requests

- Navigating Automation Help

- mapp Technology - Motion control: Basic functions

- Motion control: Basic functions - PLCopen

- Programming motion sequences

- PLCopen state diagram

- Error handling in the application

Número de modelo

SEM1112.2

Registrarse ahora Para información sobre los precios, póngase en contacto con su comercial

Lugar del evento

B&R Paris

1 rue Christian Doppler

Parc Farraday

77700 Serris

Francia

Organizador

Automation Academy France

6 allée Iréne Joliot-Curie

69800 Saint-Priest

Francia

Teléfono:

+33 / 4 72793850

Información adicional

Desde: 20.06.2024

Empezar: 09:00

Hasta: 21.06.2024

Fin: 17:00

Duración:

2 Días

Idioma: Francés