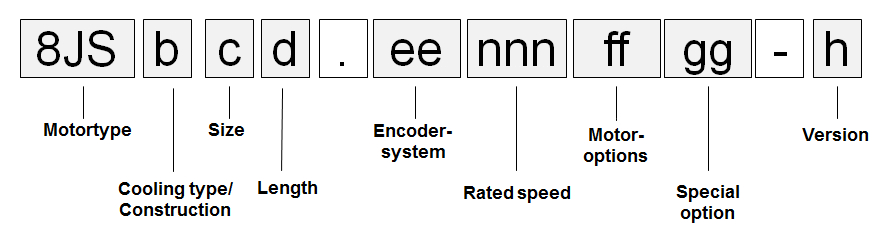

Cooling / Construction type (b)

Cooling / Construction type (b)

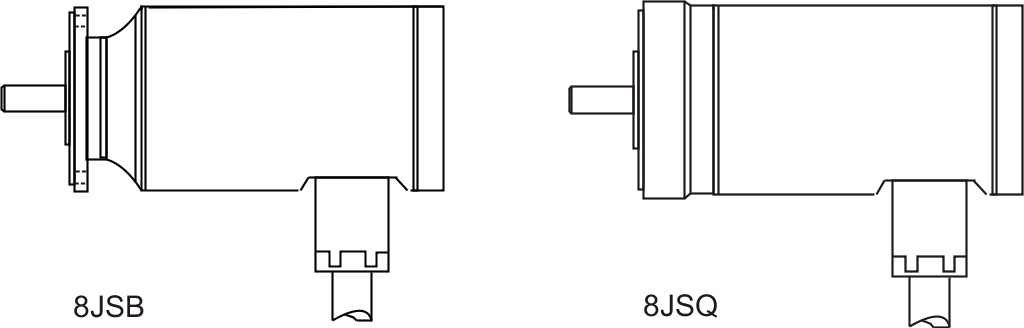

The hygiene motors in the 8JSB and 8JSQ series are self-cooled and have a stainless steel design. They are only available as a single cable (built-in hybrid connector) solution with a "straight" connection direction. The mounting method is the only difference between them.

The 8JSB series is designed with flange-mounted construction.

The 8JSQ series is designed with front-mounted construction.

|

Size (c)

Size (c)

8JSB / 8JSQ three-phase synchronous motors are available in sizes 3, 4, 5 and 6.

These differ in dimensions (especially flange dimensions) and power data. The different sizes are distinguished by a character (c) in the order number. The larger this number, the larger the flange dimensions and power data of the respective motor.

Cooling type/ Construction | Available sizes | ||||

|---|---|---|---|---|---|

3 | 4 | 5 | 6 | ||

8JS | B | Yes | Yes | Yes | Yes |

Q | Yes | Yes | Yes | Yes | |

Length (d)

Length (d)

8JSB / 8JSQ three-phase synchronous motors are available in five different lengths. These differ in the power data with identical flange dimensions. The different lengths are differentiated by a digit (d) in the order number.

Length | Available sizes | |||

|---|---|---|---|---|

3 | 4 | 5 | 6 | |

1 | Yes | Yes | Yes | --- |

2 | Yes | Yes | Yes | Yes |

3 | Yes | Yes | Yes | Yes |

4 | --- | Yes | Yes | Yes |

5 | --- | --- | --- | Yes |

Encoder system (ee)

Encoder system (ee)

8JSB / 8JSQ hygienic motors are available with optical and inductive EnDat 2.2 encoders. The encoder system is listed as part of the order number in the form of a 2-digit code (ee).

EnDat encoders

General information

Digital drive systems and position control loops require fast and highly secure transfer of data obtained from position measuring instruments. In addition, other data such as drive-specific characteristics, correction tables, etc. should also be available. To ensure a high level of system security, measuring instruments must be integrated in routines for detecting errors and be able to perform diagnostics.

The EnDat interface is a digital, bidirectional interface for measuring instruments. It is able to output position values from incremental and absolute measuring instruments and can also read and update information on the measuring instrument or store new data there. Because it relies on serial data transfer, only 4 signal lines are needed. Data is transferred synchronously to the clock signal defined by the subsequent electronics. The type of transfer used (e.g. for position values, parameters, diagnostics, etc.) is selected using mode commands sent to the measuring instrument by the subsequent electronics.

EnDat 2.2 encoders (single-turn or multi-turn) can be used depending on requirements.

EnDat 2.2 for motor size 3 and 4 - Technical data

Name | Order code (ee) | |

|---|---|---|

D4 | D5 | |

Operating principle | Optical | |

EnDat protocol | 2.2 | |

Single-turn / Multi-turn | S | M |

Revolutions | 1 | 4096 |

Resolution [bits single-turn / bits multi-turn] | 23/0 | 23/12 |

Precision ["] | 60 | |

Cutoff frequency | Digital pos. in the encoder | |

Vibration in operation stator max [m/s2] | 200 | |

Shock during operation max [m/s2] | 1000 | |

PFH (probability of dangerous failure per hour) SIL 2 | ≤15 * 10-9 | |

Manufacturer's website | www.heidenhain.de | |

Manufacturer's product ID | ECN 1123 FS | EQN 1135 FS |

EnDat 2.2 for motor size 5 and 6 - Technical data

Name | Order code (ee) | |

|---|---|---|

DA | DB | |

Operating principle | Inductive | |

EnDat protocol | 2.2 | |

Single-turn / Multi-turn | S | M |

Position values per revolution | 524 288 (19-bit) | |

Distinguishable revolutions | 1 | 4096 |

Resolution [bits single-turn / bits multi-turn] | 19/0 | 19/12 |

Precision ["] | ±65 | |

Cutoff frequency | Digital pos. in the encoder | |

Vibration during operation [m/s2] 55 to 2000 Hz | Stator: ≤400 m/s2 Rotor: ≤600 m/s2 (EN 60068-2-6) | |

Shock during operation [m/s2] Duration 6 ms (EN 60068-2-27) | ≤2000 | |

PFH (probability of dangerous failure per hour) SIL 2 | ≤15 * 10-9 | |

Manufacturer's website | www.heidenhain.de | |

Manufacturer's product ID | ECI1319 FS | EQI1331 FS |

Rated speed (nnn)

Rated speed (nnn)

The stainless steel hygiene motors in the 8JSB / 8JSQ series are available with different nominal speeds:

Size | Lengths | ||||

|---|---|---|---|---|---|

1 | 2 | 3 | 4 | 5 | |

3 | 5000 | 3000, 7000 | 2000, 4500 | --- | --- |

4 | 3000, 6000 | 3500, 6000 | 2500, 6000 | 2000, 5000 | --- |

5 | 2500 | 1500, 3500 | 3000 | 1800, 3000 | --- |

6 | --- | 1800, 5000 | 1500, 4000 | 2000, 3000 | 2000 |

Holding brake (ff)

Holding brake (ff)

8JSB / 8JSQ motors available with an optional built-in holding brake. Retrofitting is not possible. The spring action brake (24 VDC) blocks the rotor when power is not applied.

Name | Motor size | |||

|---|---|---|---|---|

3 | 4 | 5 | 6 | |

Holding torque MBr [Nm] | 2.5 | 5.3 | 14.5 | 25 |

Connection power Pon [W] | 10.1 | 12.8 | 19.5 | 25.7 |

Connection current Ion [A] | 0.42 | 0.53 | 0.82 | 1.07 |

Connection voltage Uon [V] | 24 | 24 | 24 | 24 |

Activation delay ton [ms] | 0.01 | 0.015 | 0.015 | 0.02 |

Release delay toff [ms] | 0.025 | 0.035 | 0.08 | 0.105 |

Moment of inertia JBr [kgcm²] | 0.014 | 0.068 | 0.173 | 0.605 |

Mass mBr [kg] | 0.35 | 0.63 | 1.1 | 2.0 |

Shaft end (ff)

Shaft end (ff)

The power is transmitted over the cylindrical shaft end, EN50347-compliant k6 fit with locking thread.

A keyed shaft is also available as an alternative. (The DIN 748-compliant keyway and the key correspond to DIN 6885 Form A, for stainless steel 1.4404.)

Special motor options (gg)

Special motor options (gg)

00...No special motor options

No special motor options are currently offered for 8JSB/8JSQ motors.

Motor version (h)

Motor version (h)

The motor version is automatically specified by the configurator and can be seen in the technical data.

Order code motor options (ff)

Motor option | ||||

|---|---|---|---|---|

Connection direction | Oil seal | Holding brake | Shaft end | Code for the order key (ff) |

Straight, single-cable solution (hybrid) | Yes | --- | Smooth | U6 |

Yes | --- | With key | U7 | |

Yes | Normal | Smooth | U8 | |

Yes | Normal | With key | U9 | |

Example order 1

Example order 1

A stainless steel three-phase synchronous motor of type 8JS for flange mounting (order code "B") was selected for an application. The size/length should be 43. An inductive single-turn encoder was chosen. The required speed is 2500 rpm. A brake is not required, the shaft is equipped with an oil seal, the output shaft should be smooth.

The code for the flange-mounted stainless steel motor 8JSB.

The code for the size/length is 43.

The code (ee) for the encoder system is D8.

The code (nnn) for a nominal speed of 2500 rpm is 025.

All 8JSB motors are equipped with option "single cable solution (hybrid cable) connector, straight, top". The option code (ff) is therefore always "U". The no holding brake and smooth shaft without oil seal options result in "6", so the option code is "U6"

No special options (gg), the code is 00.

The version has a fixed definition and is currently - 0.

The model number for the required motor is therefore 8JSB43.D8025U600-0.

Example order 2

Example order 2

A stainless steel three-phase synchronous motor of type 8JS for front mounting (order code "Q") was selected for an application. The size/length should be 65. An inductive multi-turn encoder was chosen. The required speed is 2000 rpm. A brake and oil seal are required (IP69K protection), the output shaft should be smooth.

The code for the flange-mounted stainless steel motor 8JSQ.

The code for the size/length is 65.

The code (ee) for the encoder system is DB.

The code (nnn) for a nominal speed of 2000 rpm is 020.

All 8JSQ motors are equipped with option "single cable solution (hybrid cable) connector, straight, top". The option code (ff) is therefore always "U". The holding brake and smooth shaft with oil seal options result in "8", so the option code is "U8"

No special options (gg), the code is 00.

The version has a fixed definition and is currently - 0.

The model number for the required motor is therefore 8JSQ65.DB020U800-0.