In principle, a power grid is a zero-sum game: whatever electrical energy is fed into it must also be consumed at the same moment – no more and no less. Sounds simple enough in theory, but is often quite different in practice. Growing numbers of photovoltaic and wind systems present grid operators with enormous challenges. After all, consumers hardly base their behavior on whether or not the sun is shining or wind is blowing. WSTECH, based in the northern German town of Flensburg, has proven that these challenges can be overcome with POWERLINK.

When generating renewable energy, it is important to comply with the legal requirements of Germany's medium-voltage directive. This applies to much more than simply feeding it the right voltage and frequency. Feed-in systems must also comply with detailed specifications with regard to the presence of disturbing harmonics and must also be able to play an active role in static and dynamic grid stabilization. All these tasks fall on the inverters that form the heart of the feed-in system. They process the DC voltage coming from the photovoltaic cells or the AC voltage coming from the wind generators with variable frequency and then feed it into the supply grid as needed.

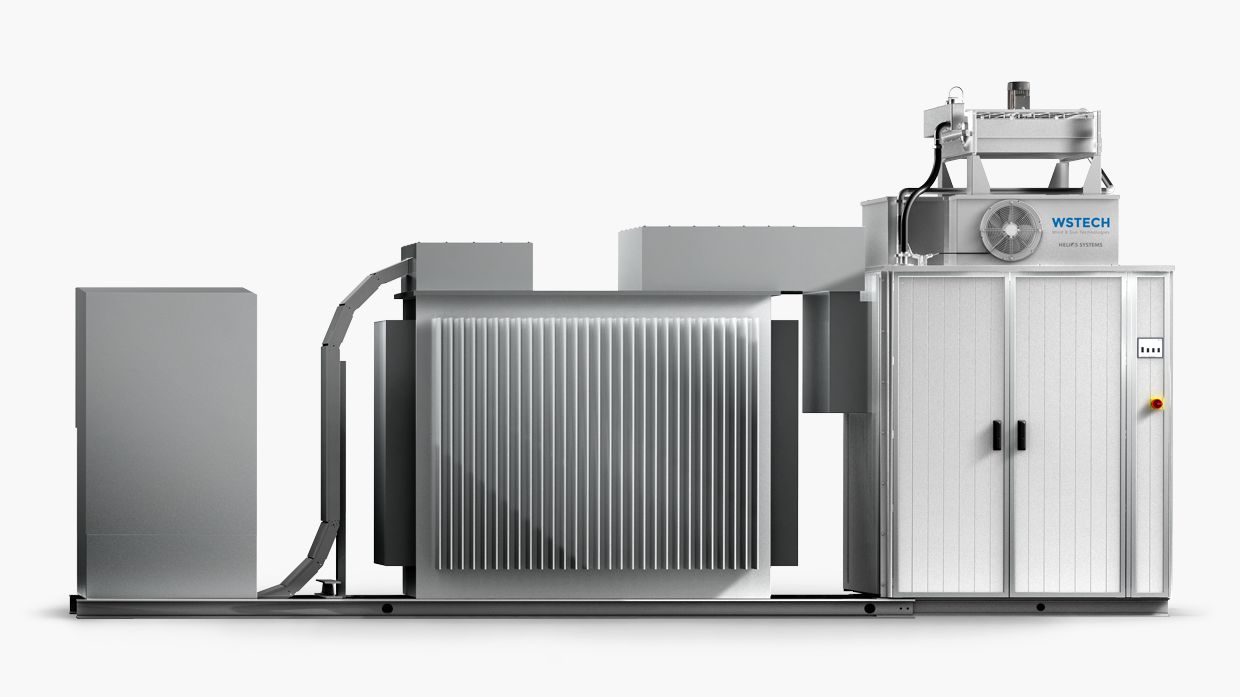

Powerful inverters from 500 to 6,000 kilovolt amperes

Since the company's founding in 2001, the approximately 100 employees of WSTECH, based in the northern German town of Flensburg, have acquired extensive know-how. Their expertise includes the development and production of controller assemblies in which the inverters are controlled with a pulse pattern via their IGBT modules. "This assembly represents our core competence and is used in all types of devices," says R&D team leader Mark Ahmling. "With its fast and accurate control loops, it ensures that the current reaches the grid in sinusoidal form and free of harmonics." To perform the trick they use to achieve this, WSTECH developers need a high-performance fieldbus that is virtually jitter-free.

POWERLINK for maximum synchronicity

By phase-shifting multiple power modules by exactly 180 degrees, the 10-kilohertz harmonics cancel each other out rather than having to be filtered out afterwards. "Not only does this trick enable us to reduce the amount of filter technology needed, it also significantly increases operational reliability," emphasizes Ahmling. It only works, however, if all the modules involved operate and communicate synchronously within a tolerance of ±2 µs.

In its search for a suitable bus system, Ahmling's team discovered B&R technology and, in particular, POWERLINK. The choice fell on a primary controller from B&R's X20 series, connected to secondary controllers, measuring boards and other components via POWERLINK. The virtually jitter-free SoC signal (= single-chip system) from POWERLINK now keeps all the components precisely synchronized and is therefore the key to success. Another factor that distinguishes this bus from its competitors is the extensive amount of data that can be exchanged in real time.

Open and independent

The use of the X20 controller has other advantages for WSTECH as well. "The VxWorks-based Automation Runtime operating system makes us independent of Microsoft and reduces the risk of malware," explains the developer. "At the same time, whenever we're looking at interfaces, openness is a key criteria." This is required in order to be able to communicate with other systems in which the Modbus protocol is currently still the standard. Remote maintenance is also important for Ahmling, as WSTECH systems are exported worldwide. This is achieved in B&R's Automation Studio engineering environment using the integrated Visual Components 4 tool and VNC server. This enables service technicians to log on to any system in the world, analyze its condition online and intervene if necessary.

Stable supply grid into the future

Generation of renewable energy results in a growing number of decentralized feed-in points. As this number rises, however so do the requirements for grid stability. To ensure this, the components involved must react ever faster to control commands from grid management systems and regulate them ever more precisely.

"Especially in the wind energy sector, communication cycles of 10 to 40 milliseconds are already standard today and will certainly become even shorter in the future. So it's certainly good to be prepared for it today," says Ahmling. And the system concept implemented by WSTECH does precisely that. It also opens up new applications for the WSTECH inverters, such as battery storage that allows excess energy to be dynamically absorbed and released on demand. One example is the lithium-ion battery storage facility in Jardelund in the German state of Schleswig-Holstein, which has an output of 48 megawatts and a storage capacity of 50 megawatt hours. This allows energy flows to be stored or fed into the grid within fractions of a second – a crucial factor in ensuring high grid stability.

Higher-level plant communication requires a standardized, real-time-capable and above all secure IT network. With the availability of OPC UA and real-time Ethernet based on the Time-Sensitive Networking standard (TSN), the B&R system supports these requirements perfectly.

| Mark Ahmling R&D Team Leader, WSTECH "With the SoC signal from POWERLINK, we are able to synchronize our systems virtually jitter-free. This enables us to achieve a high level of operational reliability and, at the same time, significant cost savings in the area of mains filters." |