Seamtec develops innovative, sustainable solutions to help its customers automate and optimize their hydroelectric power plants and biomass heating systems. The power plant and energy sector demands control technology with absolute stability, high availability and failsafe protection. At B&R, Seamtec found a partner with shared values who provides not only reliable control solutions, but also fast and effective support.

As a specialist in the field of renewable energy, Seamtec develops innovative control techniques to maximize the effectiveness of hydroelectric power plants and biomass heating systems. The company's portfolio spans the entire range of automation, control and electrical components from the level of individual sensors up to feed-in management and grid control. Seamtec also collaborates with partners, such as hydroelectric specialist WWS Wasserkraft, who use Seamtec systems in power plants ranging from 10 kilowatts to 20 megawatts. This broad perspective allows them to develop holistic solutions for their customers.

Changing tides in the energy industry

Seamtec was founded by CEO Peter Reiter in 2009 and currently has 6 employees. The visionary startup has seen substantial growth over the past few years and draws 70% of its revenue from international sales. "It will be very interesting to see how things develop over the next few years," says Reiter. "Particularly in Europe, the energy industry is at a crucial tipping point, and with our innovative products we are well prepared to face the challenges ahead."

With strong roots in the German-speaking region, Reiter also has big plans for developing markets in Eastern Europe, Asia and South America. Energy consumption is rising quickly in these regions, and the potential for hydroelectric power is even greater than in Western Europe. To broaden its stance in the industry, Seamtec is also branching out with new solutions for biomass heating systems and industrial automation. With its specially developed cloud automation solutions, the company demonstrates how well it has its finger on the pulse of Industry 4.0.

Reliable partner past and future

B&R first appeared on Reiter's radar through the real-time POWERLINK protocol, around which he originally designed his control and automation solutions. With POWERLINK and embedded Linux solutions as the starting point, the next question was how best to combine this with the control hardware.

Since POWERLINK is not only open, but also established worldwide as an IEC standard, Seamtec had access to thoroughly tested and certified hardware modules. A modular control system is particularly important for hydroelectric plants, because the individual subsystems – turbine controllers with I/O, remote components such as level sensors and control for hydromechanical equipment like sluice gates and trash rack cleaners – can operate autonomously, while also being interconnected via bus interfaces.

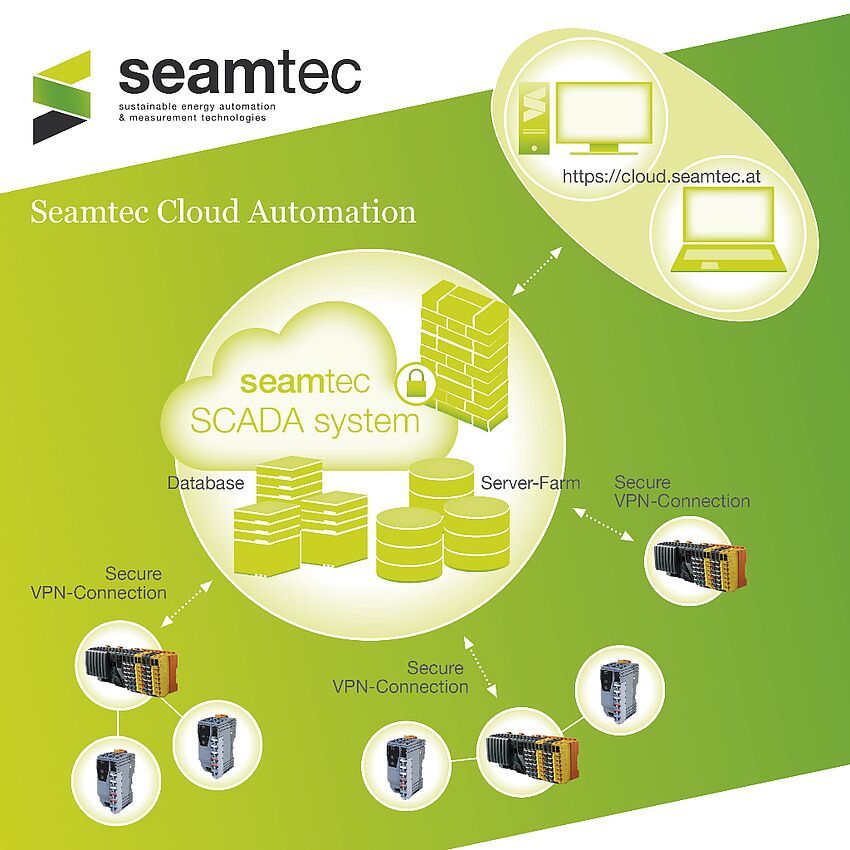

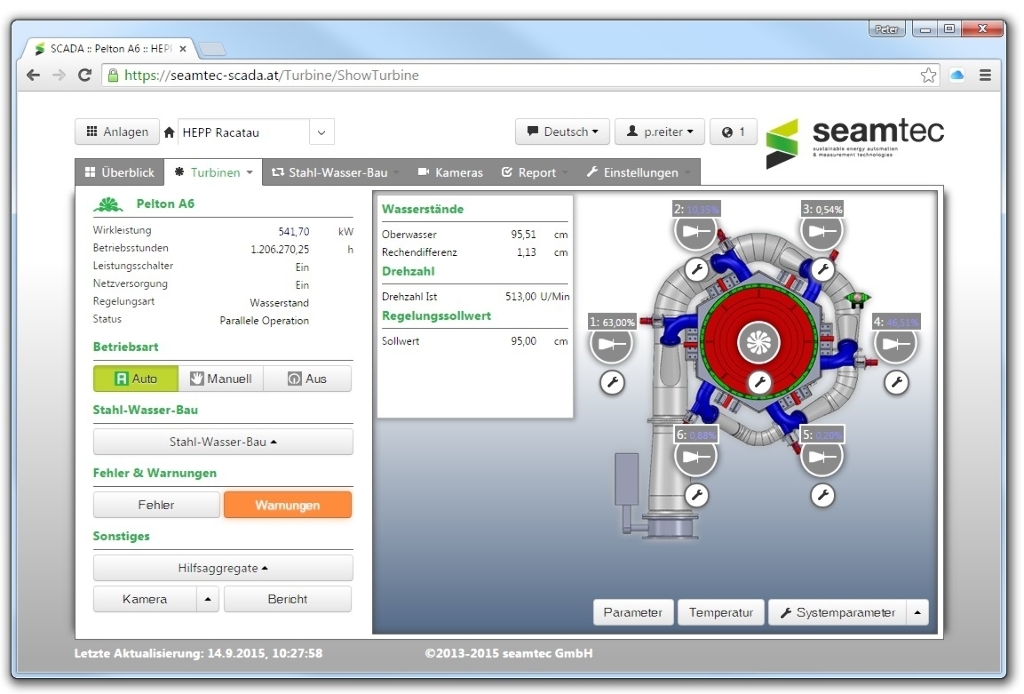

This allows communication between them to be coordinated centrally. "Together with our SEAMTEC Cloud Automation product, we also offer a modern web-based visualization solution that combines the advantages of POWERLINK and advanced cloud technologies in a single system – all based on B&R," says Reiter.

POWERLINK is an open technology and defined worldwide as an IEC standard. A modular control system is particularly important for hydroelectric plants, because the individual subsystems can operate autonomously, while also interconnected via a bus interface so that communication between them can be coordinated centrally.

An automation partner at your side

For Reiter, partnering with B&R was clearly the right strategy. "Our decision of which control components to use was tied to three criteria," he explains. "The solution would have to ensure high-availability, be extremely reliable and include local support." This third criteria was particularly important to Reiter and his team, because when a customer's system is down – or even when there is a question regarding a new development – they need a qualified contact close by to provide the necessary answers. "We need a partner for whom we're more than an anonymous number, who won't need us to retell the same story every time we call, and who won't make our customers wait weeks for a solution. That's why B&R was the clear choice," says Reiter.

From the field to the cloud

As a young and dynamic company, Seamtec relies heavily on research and development to keep it a step ahead of the competition. One such development is the company's two-level software design. At the field level, the control application developed in Automation studio is implemented on X20 controllers with corresponding I/O and POWERLINK modules.

The modular and object-oriented implementation in Automation Studio helped drastically increase the reliability of the software and streamline the process of configuring the system. To connect the various subsystems to the central operator station, Seamtec developed a state-of-the-art cloud automation system that runs on B&R industrial PCs. This system networks the individual subsystems via the PVI protocol and offers a Web-based HMI solution as well as database archiving of system data.

The main advantage of the SEAMTEC Cloud Automation System is that multiple plants can automatically archive and exchange data with the Seamtec Cloud via secure VPN connections. The customer logs into the secure cloud system once, and from there can not only monitor but also control plants all around the world in real time. This solution also has advantages for the plant manufacturer, offering central access to all plants to resolve problems, compare data or offer dynamic maintenance services for after sales support. All data is safeguarded with the latest encryption technology to ensure maximum security.

Highly efficient thanks to B&R support

"Another important consideration for us in the selection of a partner was the demand for high-availability that we're constantly faced with," notes Reiter. Particularly in projects implemented over great distances, it's important that solutions are available quickly when problems arise. Outages need to be avoided wherever possible and dealt with quickly when they do occur. "The 24/7 support that B&R offers is essential to our business," explains Reiter.

Active plant monitoring algorithms help detect faults and warn the customer of potential problems before an outage occurs. Seamtec is only able to offer this service thanks to the perfect cooperation and optimal coordination of products with B&R. This makes it possible to guarantee highly available products – even to customers on the other side of the world.

"We chose B&R based on the reliability and high availability of their automation solution as well as the quality of their local support." Peter Reiter, CEO, Seamtec

Seamtec sets sights on developing markets

The scope and level of service that Seamtec offers is just one of the ways that its nearly 50 systems installed around the world stand apart from the competition. The constant growth of the renewable energy market raises new challenges all the time. To address the challenge of revitalizing aging plants – a frequent requirement in developing markets – Seamtec developed a special low-cost solution. This solution offers an easy yet high-quality way to upgrade plants with improved availability, secure and easy remote maintenance and optimized overall efficiency.

The Cloud Automation System sets new standards in automation, which is why Seamtec is working to adapt it for other industries, such as biomass systems and industrial automation. This is what it looks like when Industry 4.0 is put into practice – with B&R as a reliable expert partner.