It seems everyone these days is talking about OPC UA and TSN. For many machine builders and plant operators, however, it remains unclear what specific advantages stand to be gained from using these technologies in their own equipment and facilities.

To shed some light on the matter, we got networking specialist Stefan Bina to answer some of the most important questions about OPC UA over TSN and its role in the future of Industrial IoT communication.

Connectivity and the Industrial IoT

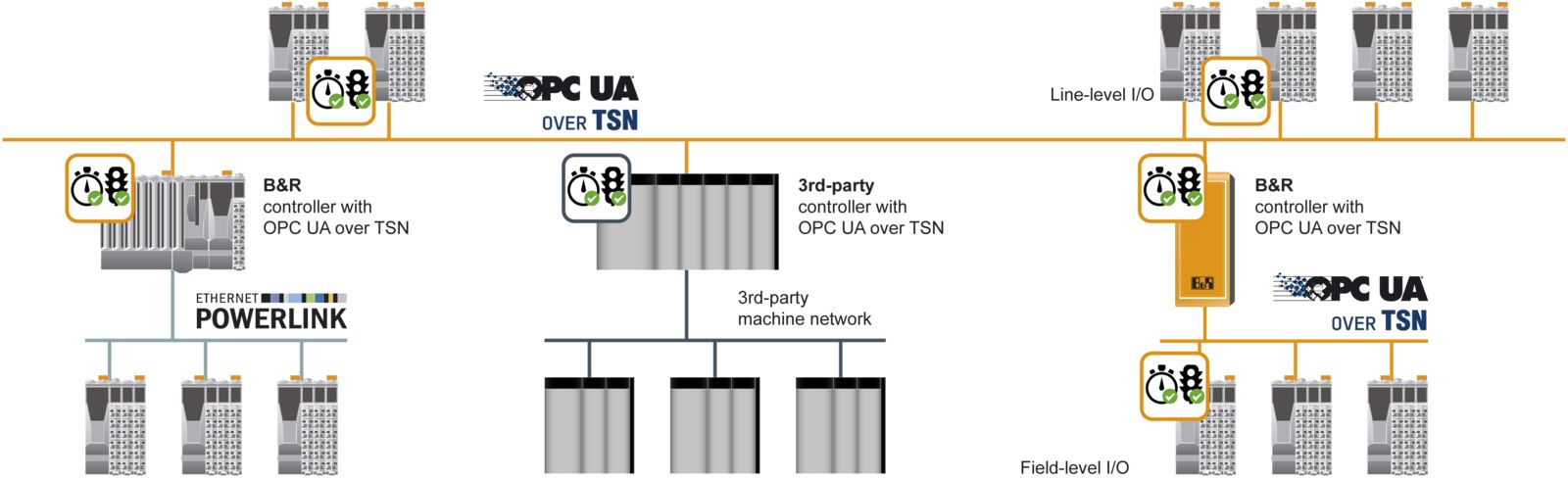

OPC UA over TSN is supported by all major automation suppliers. It ensures vendor-independent interoperability for all relevant industrial use cases, today and tomorrow.

OPC UA over TSN enables secure-by-design modular machine concepts and flexible production architectures on the shop floor. These will help users streamline their machines and plants for economical batch-size-one production. Additionally, offers secure insight into manufacturing processes for ongoing performance optimizations and predictive maintenance – without disturbing machine operations.

OPC UA over TSN is 100% open, significantly faster and secure. It can increase your ability to innovate, maximize your OEE, lower your TCO and streamline commissioning and maintenance.

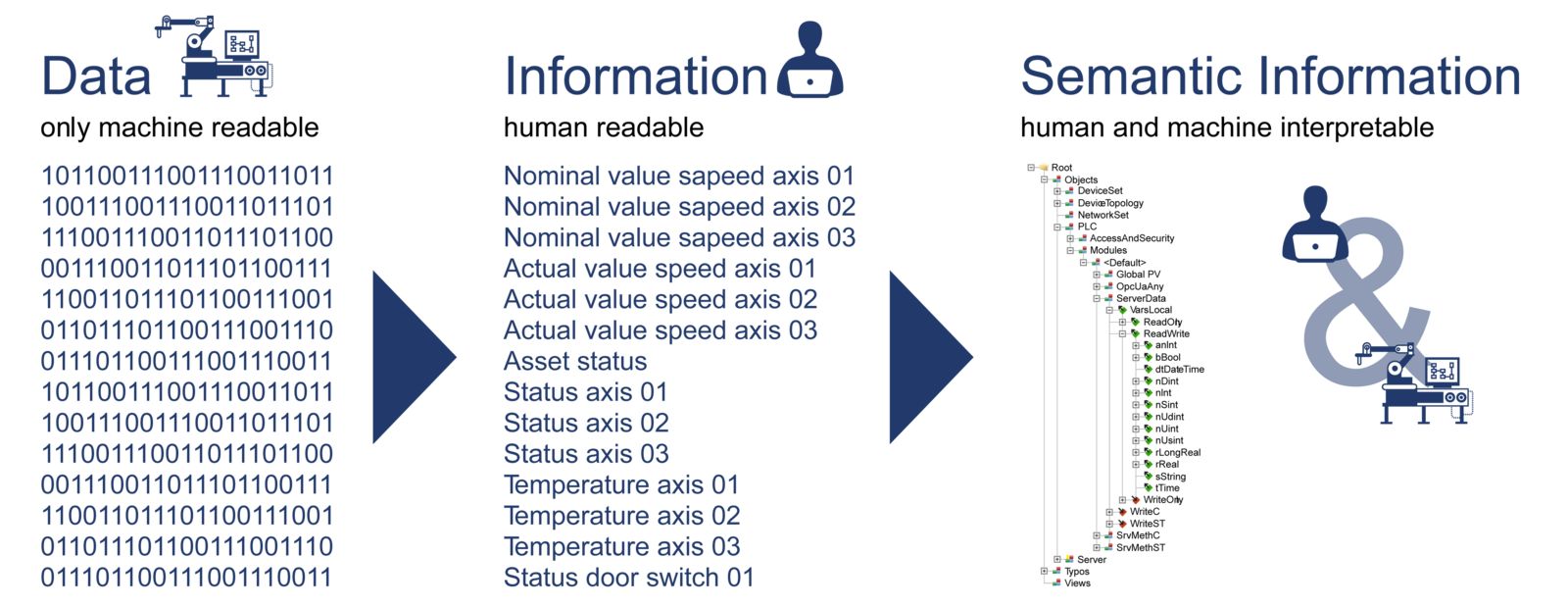

Today's proprietary fieldbus systems communicate using raw data – just zeros and ones. Without the corresponding tables, devices on the network don't know how to interpret that data. That makes it impossible to achieve the kind of seamless communication required in the Industrial Internet of Things (IIoT).

With its information model, OPC UA enriches the raw data with semantic descriptions. These give it context and meaning, so any device or person that receives the information can correctly interpret it without any further explanation.

OPC UA offers so-called methods that enable direct interaction with assets. Machines can query each other to find out what kind of services, interfaces and capabilities they provide – which enables them to interact more efficiently and autonomously.

For more information on the OPC UA information model and why we need semantics, see the OPC Foundation website.

|

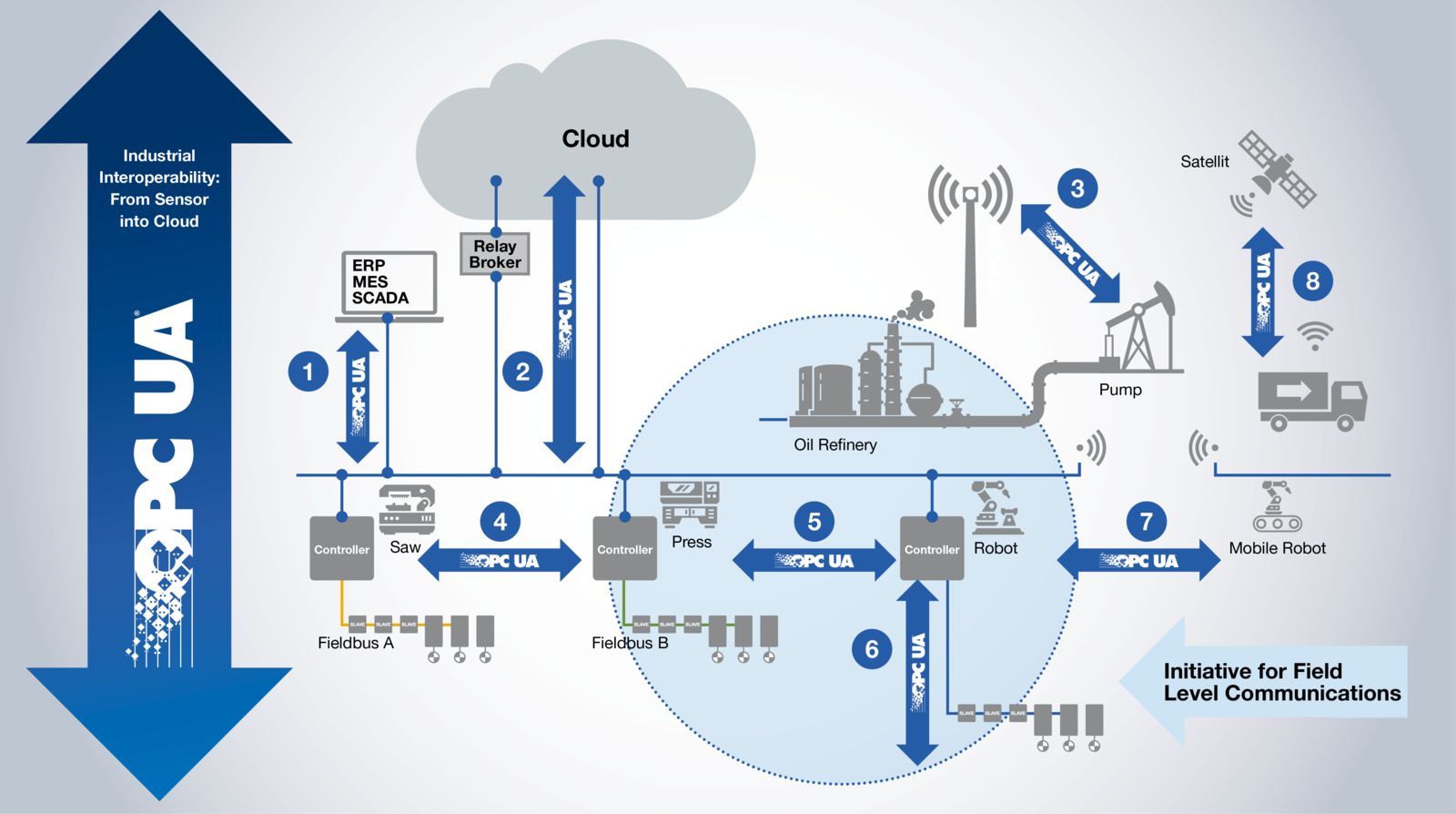

TSN's determinism allows machine-to-machine OPC UA communication to better synchronize a multi-vendor plant floor. The same holds true for device-level communication within the machines themselves.

OPC UA provides a standardized way to structure data. It adds semantics for any kind of asset and provides it in a secure manner. TSN is the infrastructure, the highway that OPC UA drives on in a deterministic way.

Without the interoperability provided by OPC UA over TSN, these multi-vendor communications would have to be hard-coded – adding exorbitant development costs and canceling out any gains in flexibility. On top of that, OPC UA over TSN guarantees continuous insight without disturbing machine operations.

Industrial IoT applications are data driven – information is their lifeblood. OPC UA over TSN adds a vast array of sensors, actuators and other automation devices to the available pool of information by extending the semantic self-description of the OPC UA information model down to the field level.

The Industrial IoT promises us an ability to design efficient and effective production processes that are at the same time cheaper and easier to commission and maintain. It also promises to allow profitable mass customization of products.

To achieve these aspirations, today's production lines will need to be transformed into flexible production units that allow continuous insight into their internal workings. This insight, combined with clever algorithms – even artificial intelligence – will be the fuel that powers ongoing performance optimizations and predictive maintenance.

|

Interoperability

It is true that we have gotten this far without it. Yet, to take automation to the next level, with ready exchange of information, digitalization of manufacturing and the rise of the smart factory and autonomous operations – interoperability is an essential stepping stone.

Interoperability brings added speed, flexibility and cost-efficiency, without which it is impossible to implement the advanced data acquisition, analysis and optimization required for the Industrial IoT.

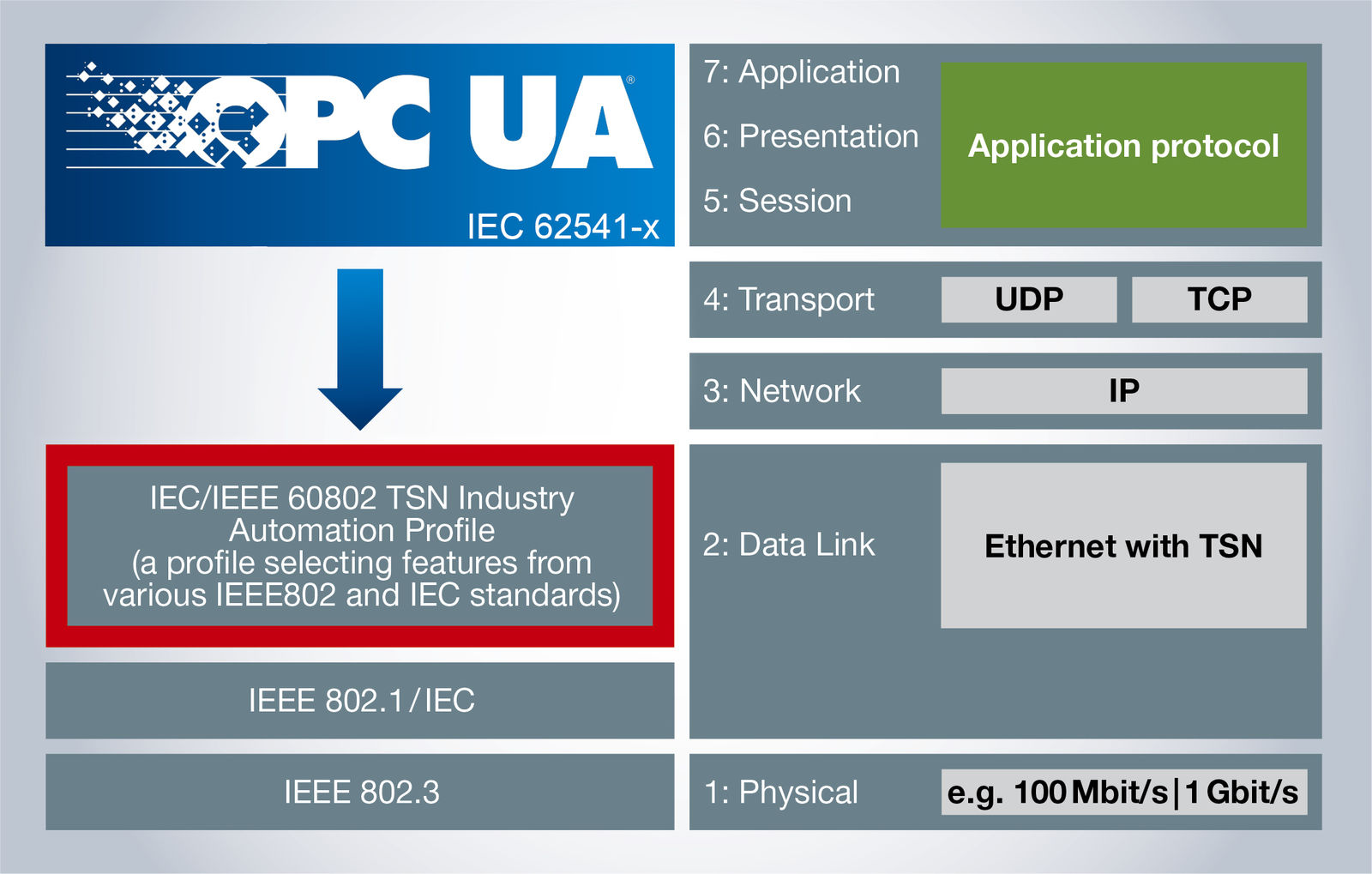

As a framework for thinking about communication systems, the OSI reference model divides them into seven conceptual layers – from the connectors and cables up to the user interface.

To ensure seamless interoperability on a network, you need interoperability on all seven of these layers. OPC UA delivers secure information interoperability on layers 5-7, allowing secure vertical communication from the sensor to the cloud. Interoperability on layers 3 and 4 is ensured through common IT standards. Layer 1 is covered by the Ethernet standard.

As the final piece in the puzzle, Time Sensitive Networking (TSN) brings interoperability to layer 2, the data link layer. This makes it possible to use OPC UA for precise real-time applications in converged OT/IT networks with unprecedented performance.

|

Ecosystem and standardization

OPC UA itself is developed and standardized by the OPC Foundation. The TSN standards are the responsibility of the IEEE 802.1 working group. To ensure a cohesive, open approach to implementation of OPC UA together with TSN and associated application profiles, the OPC Foundation has launched the new Field Level Communications initiative. The director of the working initiative is Peter Lutz, who will lead and drive forward the development of the initiative and specifications.

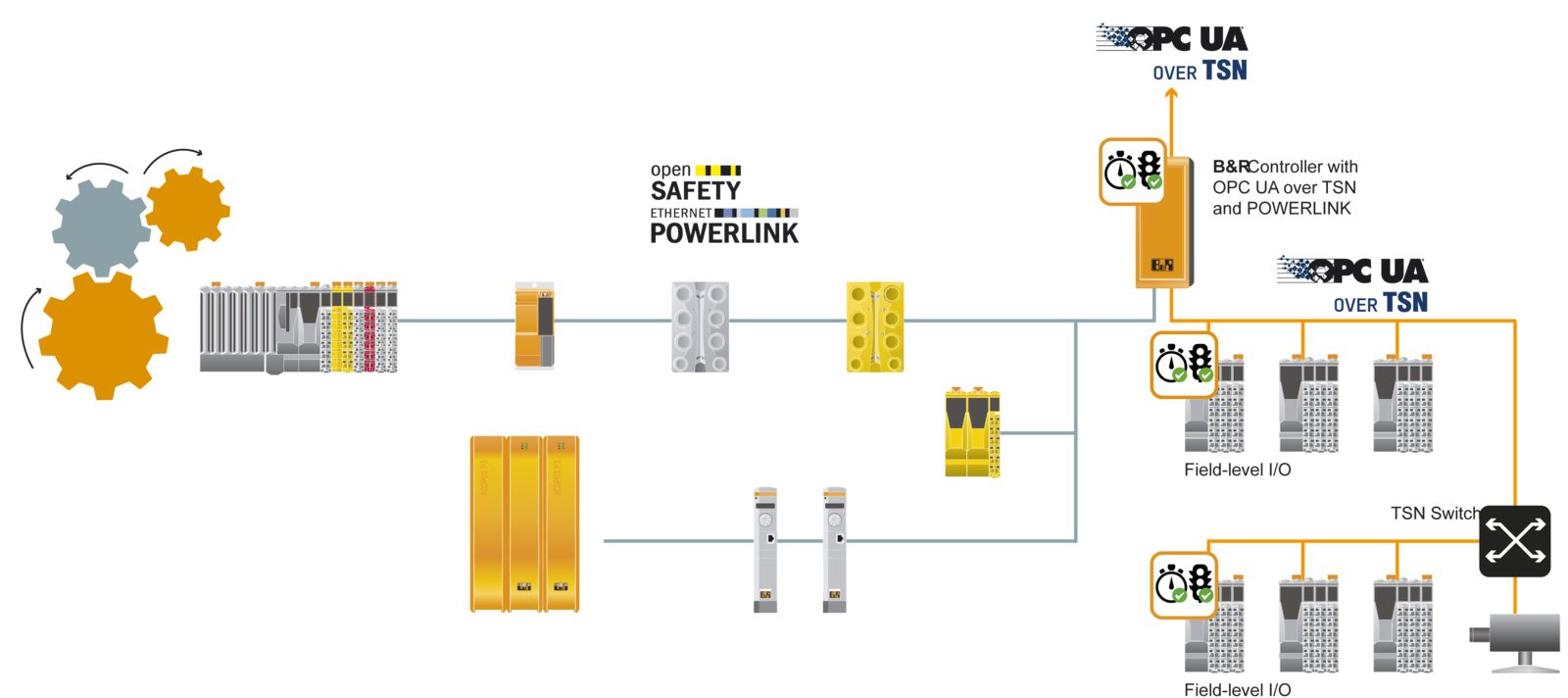

The technology will bring vendor-independent, end-to-end interoperability into field-level devices used in all areas of industrial automation. Integrating field devices and the shop floor will further solidify the OPC Foundation's role as the driver for a worldwide industrial interoperability standard. Standardization efforts for unified functionality currently taking place at the OPC Foundation include I/O, motion and safety applications.

The OPC Foundation's steering committee for field-level communications consists of 24 leading technology providers from the automation industry, including ABB, Beckhoff, Bosch-Rexroth, B&R, Cisco, Hilscher, Hirschmann, Huawei, Intel, Kalycito, KUKA, Mitsubishi Electric, Molex, Omron, Phoenix Contact, Pilz, Rockwell Automation, Schneider Electric, Siemens, TTTech, Wago and Yokogawa. More and more companies are joining all the time, with recent additions including Moxa and Murr Elektronik.

Image source: OPC Foundation |

Real-time communication is critical for industrial automation capabilities such as device-level control, motion control, machine vision and machine-to-machine (controller-to-controller) control. Yet, standard Ethernet was never designed to be a deterministic network, so proprietary fieldbus systems each implemented their own mechanisms to achieve deterministic behavior. TSN now extends IEEE 802 Ethernet to include real-time communication, providing a unified standard that meets the requirements of industrial automation.

TSN also enables the possibility of converged networks, allowing the same network to manage both non-deterministic IT communications and deterministic OT communications, such as machine control and safety. In the future, the TSN standard will be a standard feature of mainstream Ethernet chips.

For more information, see Wikipedia and the Website of the IEEE.

Performance

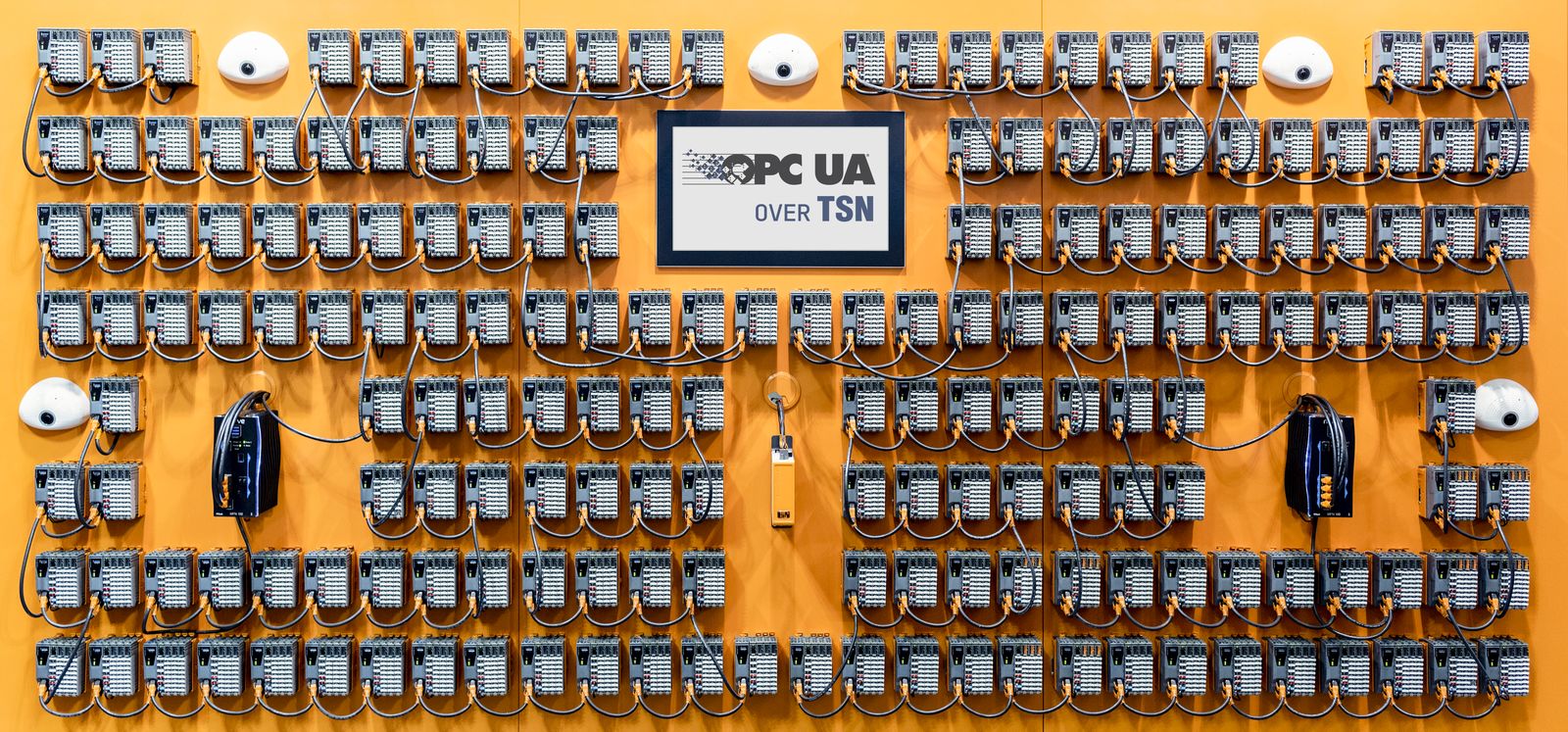

The technology is capable of addressing more than 10,000 network nodes, scalable from 10 megabits to 10 gigabits and beyond. Testing conducted by B&R achieved cycle times below 50 microseconds with a jitter of less than ±100 nanoseconds in a network of 200 remote I/O bus couplers totaling 10,000 I/O points. This is consistent with claims that OPC UA over TSN is "18 times faster than today's fastest solution".

This level of performance makes proprietary fieldbus networks obsolete. OPC UA over TSN allows high-performance motion control traffic and bandwidth-intensive IT traffic on a single cable without interference between them.

A detailed white paper on the topic of OPC UA over TSN implementation can be downloaded from the B&R website.

|

Cybersecurity and migration

OPC UA was designed to communicate with IT systems. OPC UA over TSN will enable you to converge OT and IT networks without disturbing machine operations. This is thanks to TSN and the use of OPC UA security mechanisms familiar to IT departments today, including user authentication and authorization, encryption and certificate handling.

The main advantages are openness, consistent semantics, security and performance. The performance aspects include high bandwidth and guaranteed real-time communication.

Whereas a machine builder would otherwise need to support every major fieldbus over TSN, the combination OPC UA with TSN mechanisms for real-time field-level communication gives you a single vendor-agnostic network and protocol all the way from the sensor to the cloud.

An end user may be concerned with converged networks, for example, and need the ability to use OPC UA to connect to the cloud over MQTT. Cloud, ERP and DCS platforms today support an OPC UA connector, simplifying communication. Regardless of the manufacturer of a machine, OPC UA companion specifications allow the machines to describe themselves in a consistent manner, with standardized semantics. The VDMA robot companion specification, for example, provides a standardized information model which is capable of presenting all robot related information and functionality regardless of manufacturer or location in a uniform manner.

The ARC Advisory Group has published an informative brief on the subject.

The OPC Foundation has a good track record of its members supporting OPC UA. This is one of the reasons OPC Foundation was chosen by the participating suppliers to develop OPC UA for deterministic communication using TSN.

Those 24 companies share a common vision and participate in a steering committee for the Field Level Communications initiative, dedicated to extending OPC UA for field-level communication over TSN for seamless OPC UA communication from sensor to cloud.

With their clear position in support of that vision, it can be expected that all 24 companies will release automation products with OPC UA over TSN in the upcoming years – the first set to arrive in 2020. This enormous momentum will convince other vendors and integrators to follow the market trend of a unified communication solution and contribute to the largest ecosystem of connected industrial automation solutions in history.

The topologies commonly used in industrial networks are all supported – including line, star, tree and ring. TSN includes a standard mechanism for seamless, real-time redundancy implemented through cable redundancy, ring or mesh topologies.

The supplier's development suite will provide everything necessary to make configuration simple and automated. For those who choose not to use the supplier's tools, the necessary configuration interfaces are open standards and additional third-party network tools are available.

Yes, because TSN is an evolution of standard Ethernet. TSN simply enhances standard Ethernet with real-time capabilities, so it is possible to have standard Ethernet devices and TSN devices present in the same network.

Standard Ethernet devices would not need any interface or gateway to connect to a TSN network. However, only TSN-capable devices will be able to communicate in real time.

Yes, it will be possible to synchronize POWERLINK and OPC UA over TSN devices in B&R systems.

|

B&R has always followed a sustainable product strategy ensuring long-term availability of products and technologies. This will not change with the market introduction of OPC UA over TSN. B&R will support POWERLINK parallel to OPC UA over TSN in its extensive product portfolio. Customers will be able to select the best communication solution to suit their needs.

|

TSN capability is already built into the majority of B&R's newer Automation PCs and will be supported in all new PLCs to come. The TSN and Ethernet port will be one and the same.

TSN in combination with existing fieldbusses

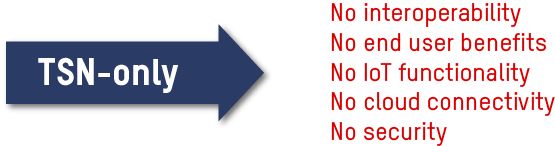

The legacy fieldbus protocols would share a common TSN network, but the devices would not be interoperable as OPC UA devices would be. These protocols also lack the semantics and methods that OPC UA provides. OPC UA has built-in security and is recognized an international standard for communication from sensor to cloud with new developments being added all the time.

The key difference is system interoperability: without it, you are locked into one vendor and one automation solution, with no ability to communicate or synchronize with other systems. In a multi-vendor plant, this means you are unable to secure your communication and implement advanced functionality such as condition monitoring, line balancing, predictive maintenance, machine optimization and plug-and-produce startup and maintenance. As a machine builder, this means you are limited to the level of innovation offered by your chosen vendor.

|

Availability

The first products will be announced by suppliers in late 2019 and available in early 2020. Contact your preferred suppliers to learn more about their commercialization plans.

Stay informed

Subscribe to the OPC Foundation newsletter OPC foundation newsletter or ask your B&R representative. For participation and direct answers, you can also get in touch with Peter Lutz:

Peter Lutz, Field Level Communications Director

OPC Foundation

Peter.Lutz@OPCfoundation.org