8LT | b | c | d | . | ee | nnn | ff | gg | - | h | ||||||||||||||||

Kühlart / Bauform | ||||||||||||||||||||||||||

Baugröße | ||||||||||||||||||||||||||

Baulänge | ||||||||||||||||||||||||||

Motorgebersystem | ||||||||||||||||||||||||||

Nenndrehzahl | ||||||||||||||||||||||||||

Motoroptionen | ||||||||||||||||||||||||||

Sondermotoroptionen | ||||||||||||||||||||||||||

Motorversion | ||||||||||||||||||||||||||

Bestellschlüssel geben nur in Ausnahmefällen Aufschluss über die möglichen Kombinationen.

Informationen zur Kombinierbarkeit sind im configuratore CAD abrufbar.

Weitere Informationen

Torque Motoren 8LT

Allgemeine Motordaten 8LT

Bestellschlüssel 8LT

Kühlart / Bauform (b)

Kühlart / Bauform (b)

8LT | b | c | d | . | ee | nnn | ff | gg | - | h | |||||||||||

8LT torque motors are available in cooling types 8LTA, 8LTB, 8LTJ, 8LTK, 8LTQ and 8LTS.

Cooling types are distinguished by a character (b) in the model number.

Cooling type (b) | Shaft end | |

|---|---|---|

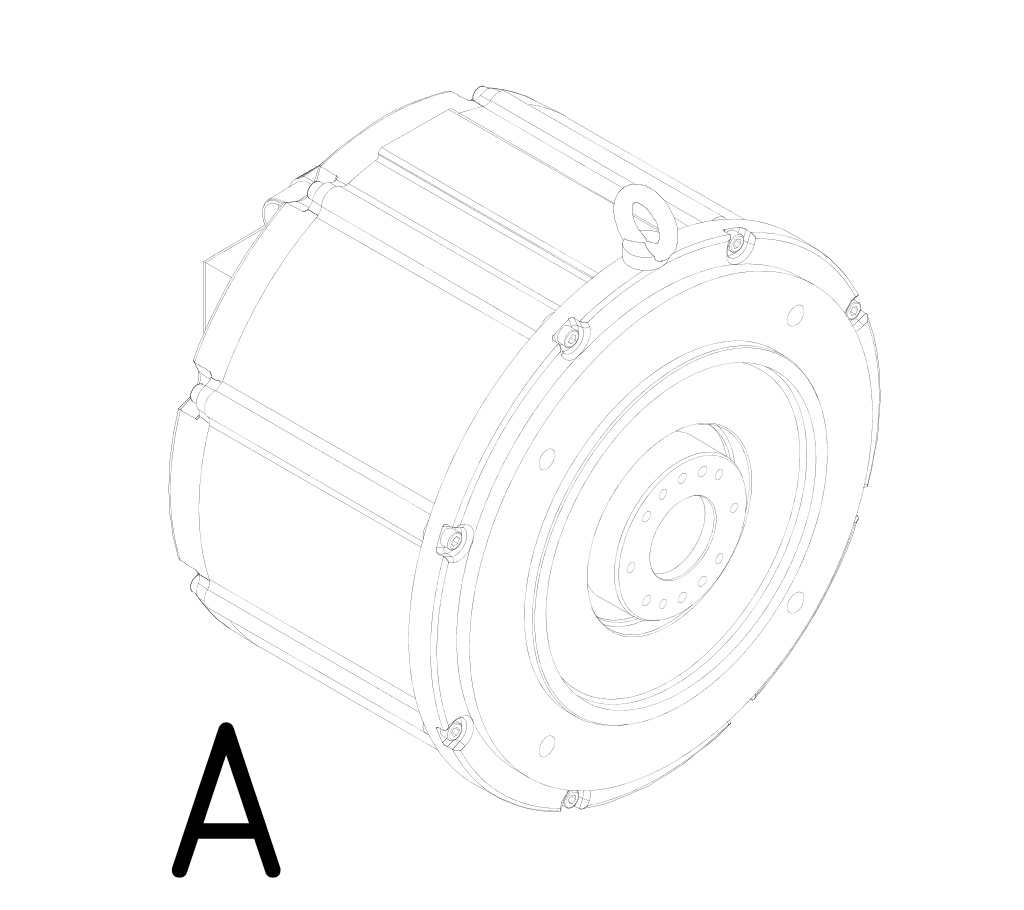

8LTA | Self-cooling | ISO output flange |

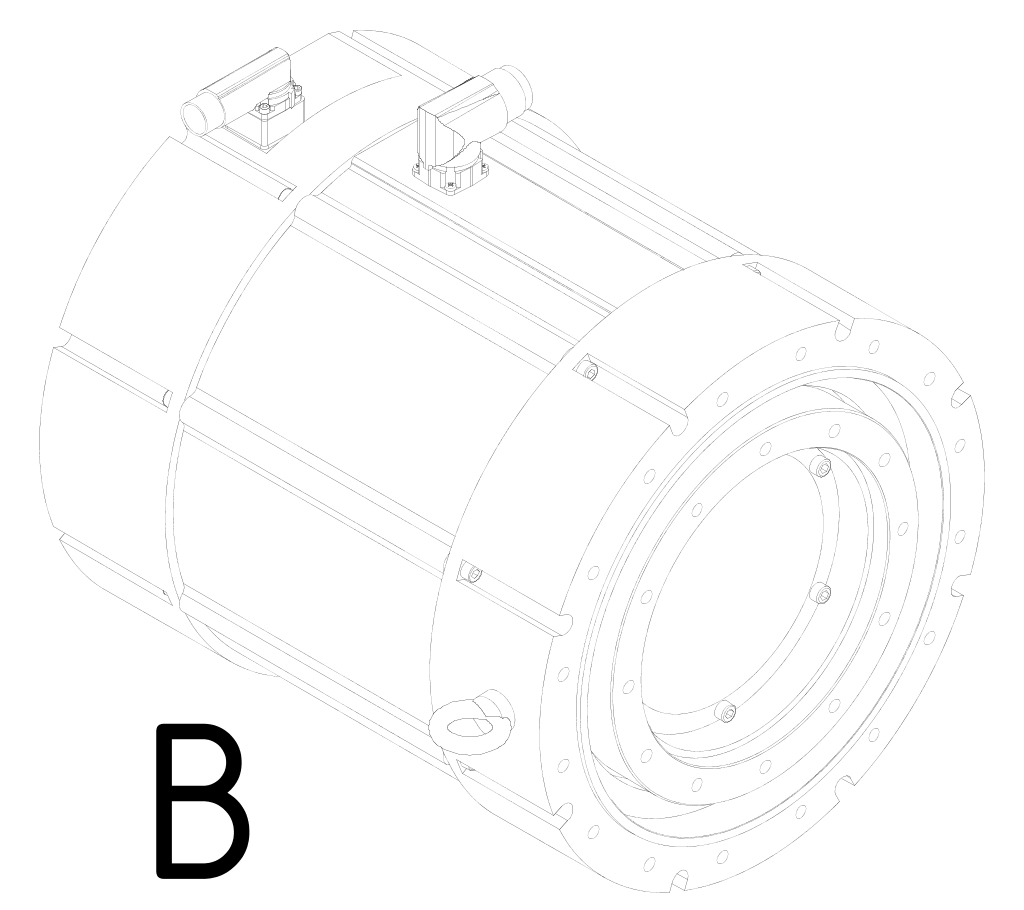

8LTB | Hollow shaft | |

8LTJ | Liquid-cooled | ISO output flange |

8LTK | Hollow shaft | |

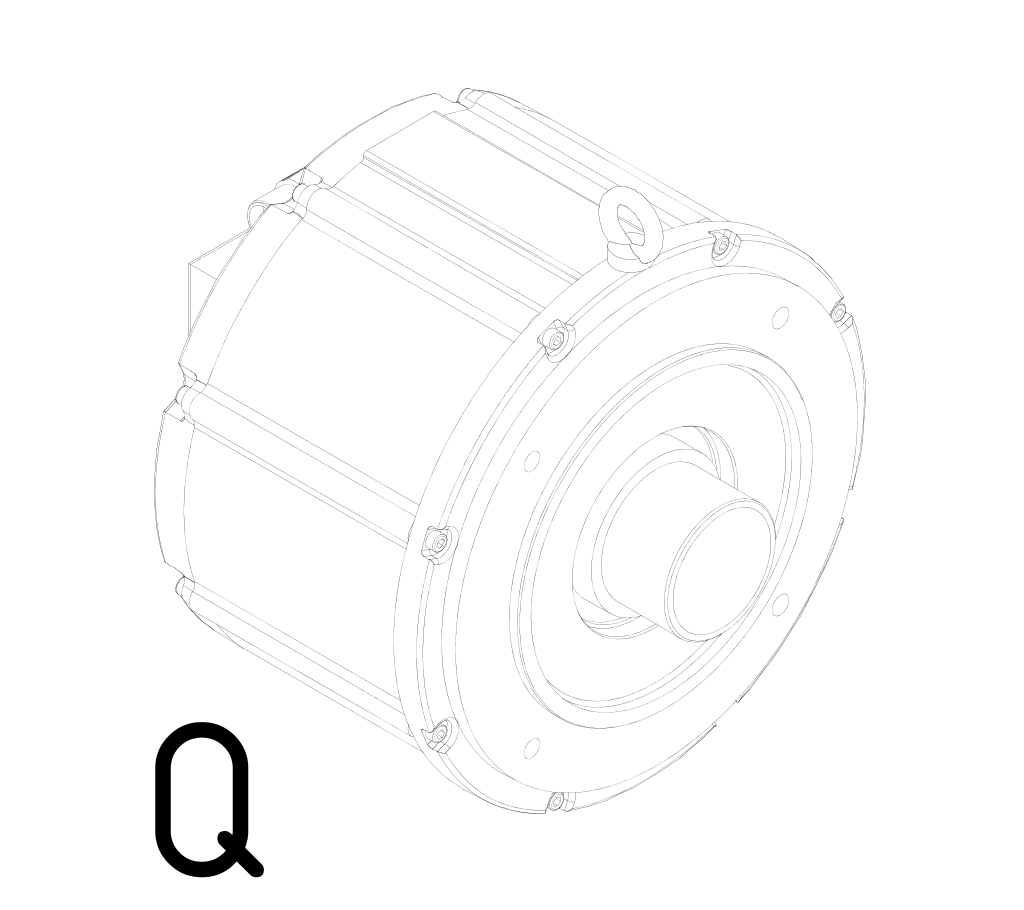

8LTQ | Self-cooling | Shaft with blind hole |

8LTS | Liquid-cooled | |

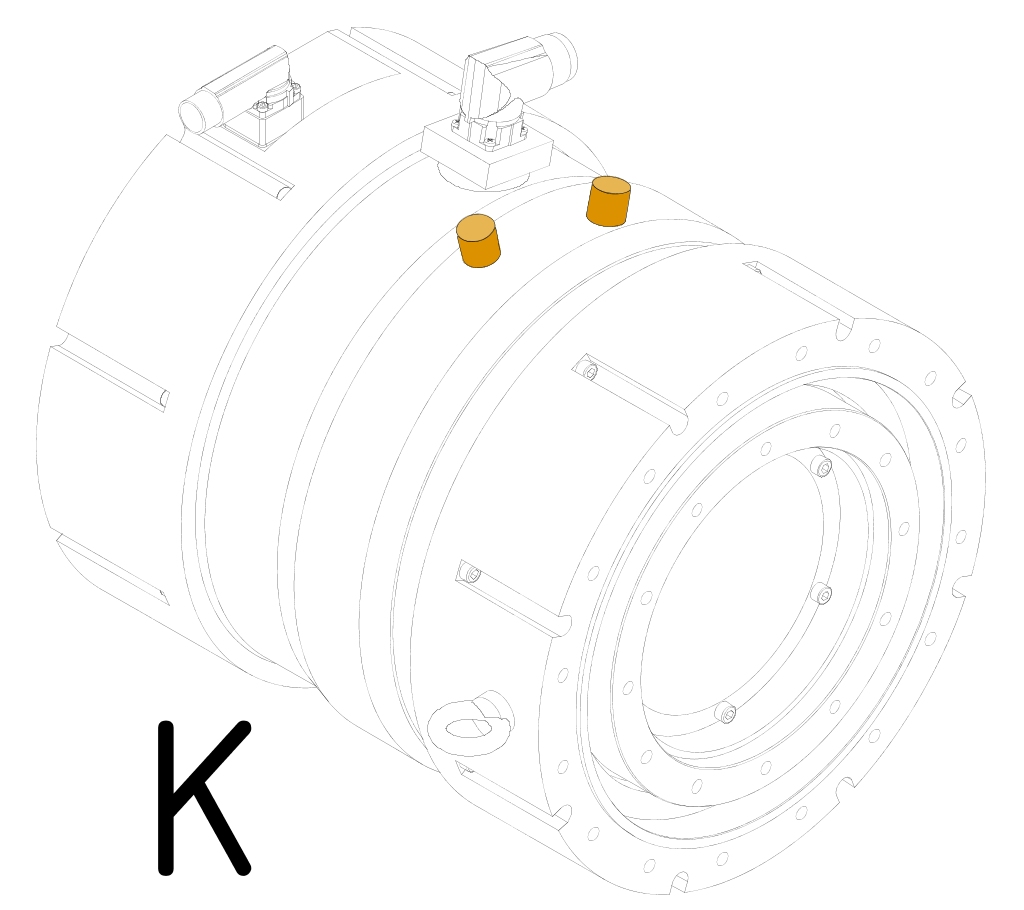

Self-cooling motors

ISO output flange | Hollow shaft | Shaft with blind hole |

|---|---|---|

|  |  |

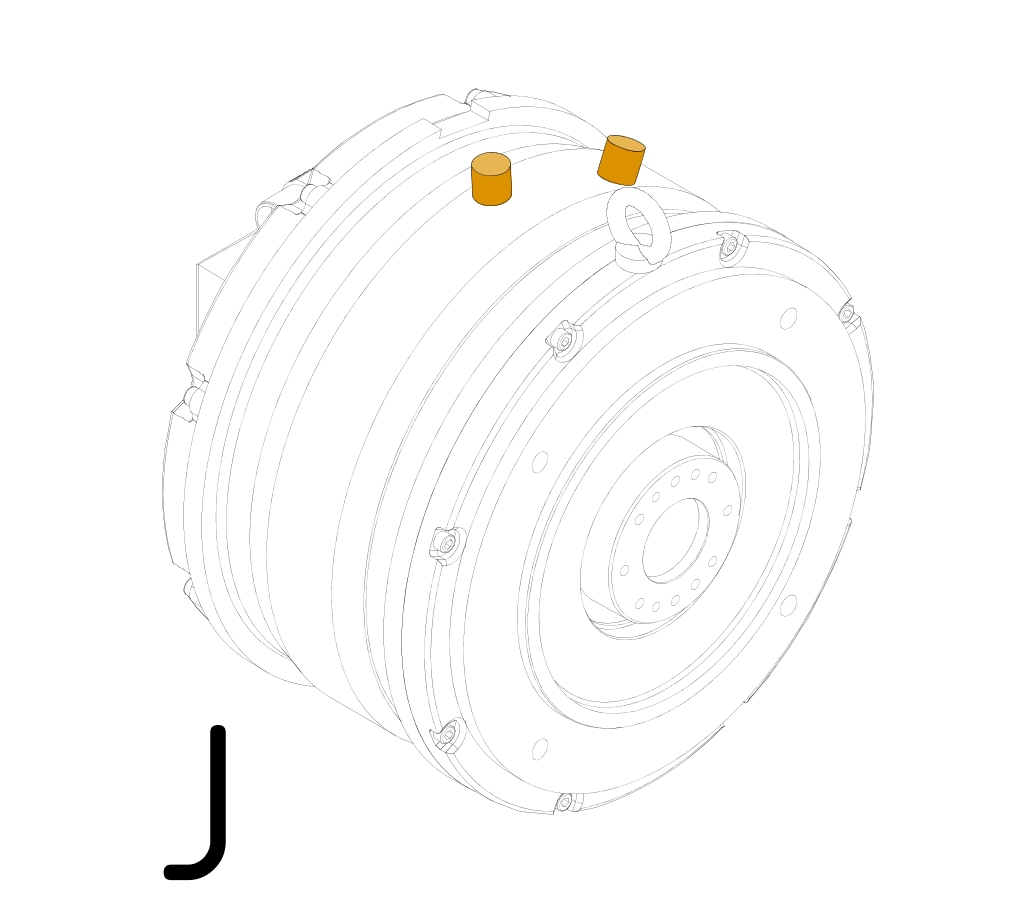

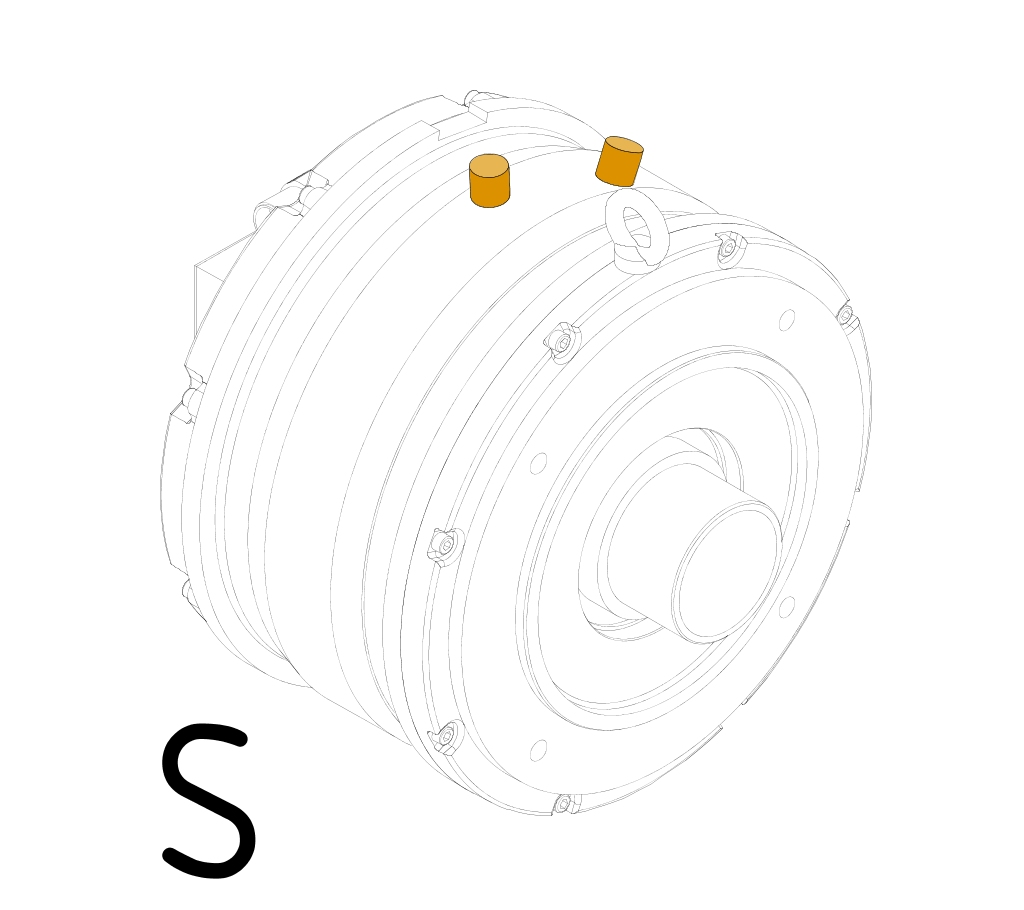

Liquid-cooled motors

ISO output flange | Hollow shaft | Shaft with blind hole |

|---|---|---|

|  |  |

Baugröße (c)

Baugröße (c)

8LT | b | c | d | . | ee | nnn | ff | gg | - | h | |||||||||||

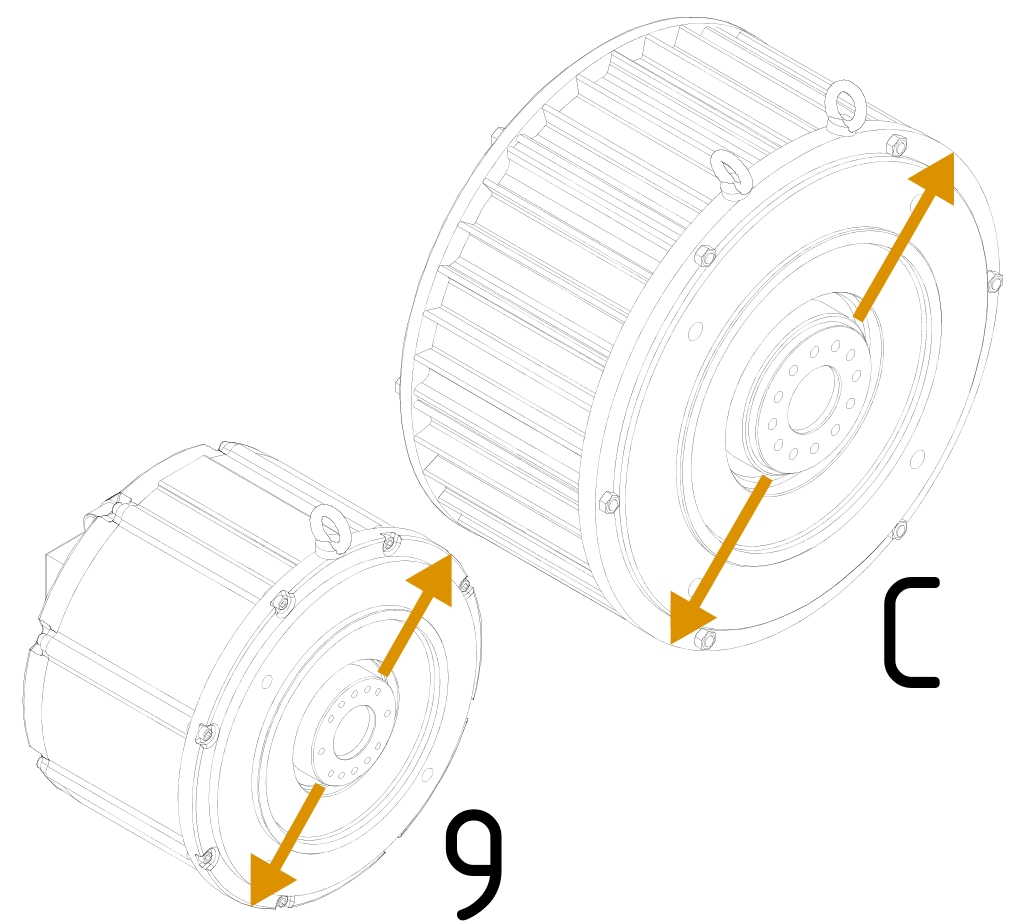

| 8LT torque motors are available in various sizes (9 and C). These differ in dimensions (especially flange dimensions) and power data. The sizes are distinguished by a character (c) in the model number. The list of sizes is ascending. |

Verfügbarkeit

Available sizes (c) | ||

|---|---|---|

8LTx9 | 8LTxC | |

8LTA | Yes | Yes |

8LTB | Yes | --- |

8LTJ | Yes | Yes |

8LTK | Yes | --- |

8LTQ | Yes | Yes |

8LTS | Yes | Yes |

Baulänge (d)

Baulänge (d)

8LT | b | c | d | . | ee | nnn | ff | gg | - | h | |||||||||||

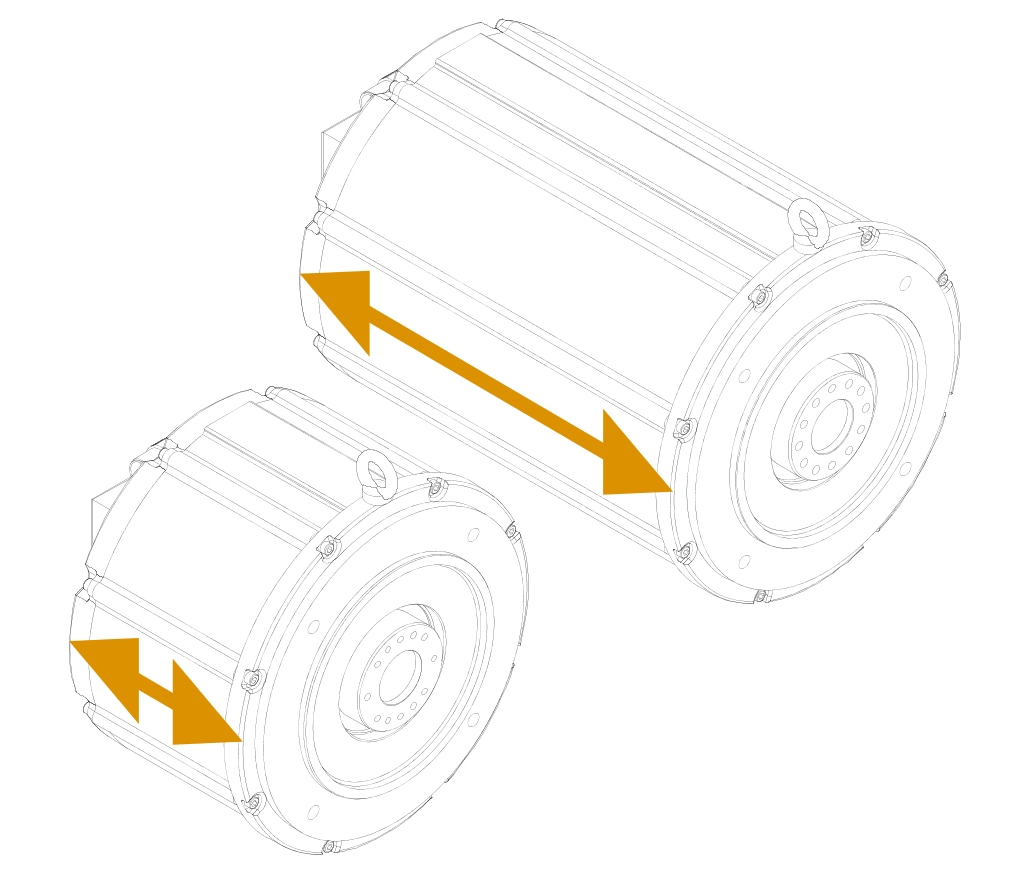

| 8LT torque motors are available in various lengths. These differ in the power data with identical flange dimensions. The lengths are distinguished by a number (d) in the model number. The larger this number, the longer the respective motor. |

Verfügbarkeit

Available lengths (d) | ||||||

|---|---|---|---|---|---|---|

8LTxx3 | 8LTxx4 | 8LTxx5 | 8LTxx6 | 8LTxx7 | 8LTxx8 | |

8LTx9 | YesNot available for 8LTB / 8LTK | Yes | Yes | Yes | Yes | --- |

8LTxCNot available for 8LTB / 8LTK | Yes | Yes | Yes | Yes | Yes | Yes |

Motorgebersysteme (ee)

Motorgebersysteme (ee)

8LT | b | c | d | . | ee | nnn | ff | gg | - | h | |||||||||||

8LT torque motors are equipped with a magnetic or EnDat encoder. The encoder system is specified as part of the order number in the form of a 2-digit code (ee).

Magnetischer EnDat Geber

With the hollow-shaft motor variant (8LTB and 8LTK), EnDat 2.2 encoders (M0) with distance-coded absolute position are used.

Commissioning

When started for the first time, the motor does not detect its actual position. A shaft movement of ≤18° degrees is required for detection. Preferably in single-phase mode (stepper mode).

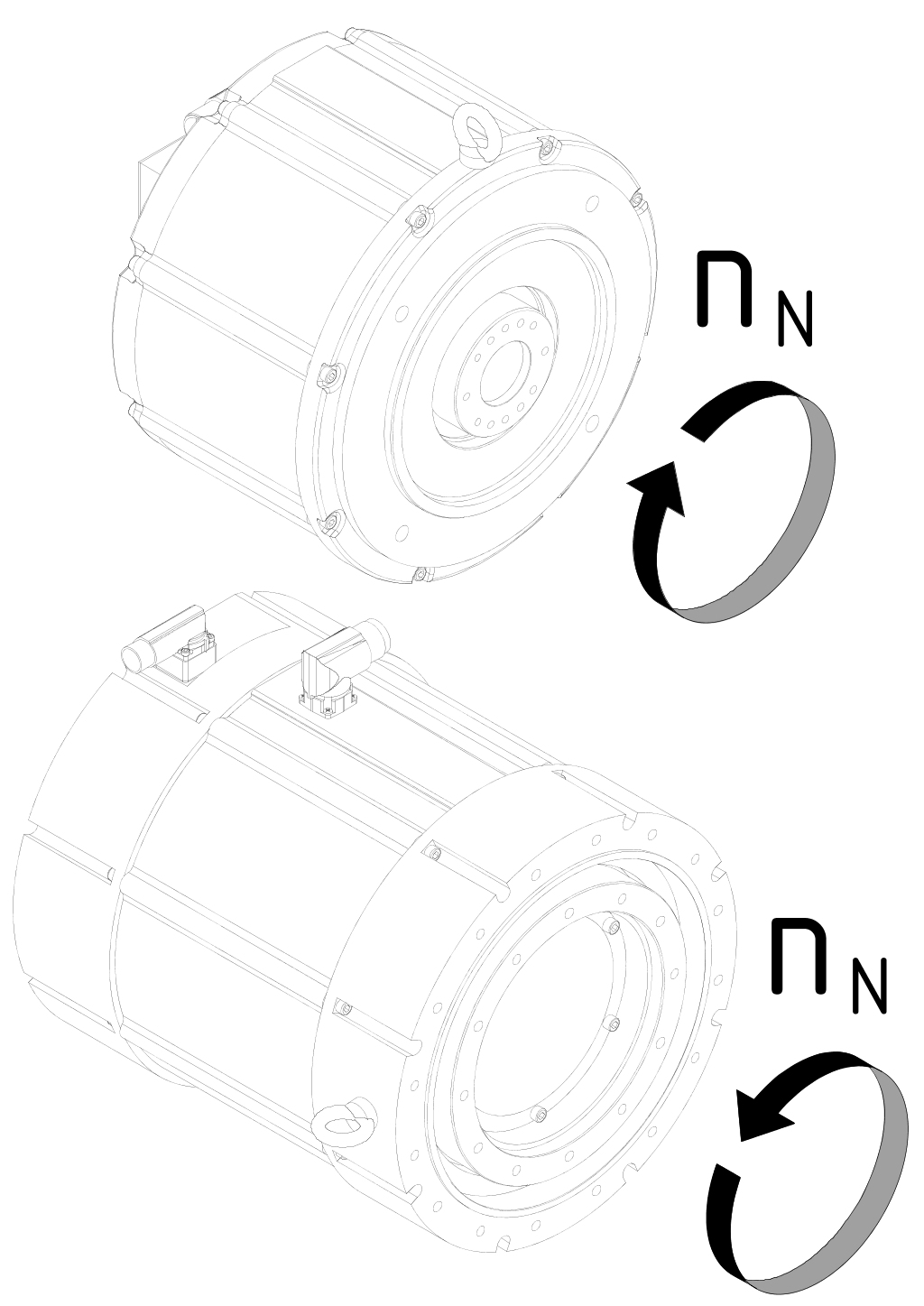

Drehrichtung

Hohlwellenmotoren (8LTB / 8LTK) weichen von der üblichen Drehrichtung (rechts) ab und werden linksdrehend ausgeliefert. Eine softwareseitige Anpassung auf rechtsdrehend ist durch den Anwender möglich.

Encoder type / Order code | M0 |

|---|---|

Operating principle | Magnetic |

EnDat protocol | 2.2 |

Functional safety | No |

Single-turn/Multi-turn | S |

Revolutions | 1 |

Resolution [bits single-turn / bits multi-turn] | 14/0 |

Accuracy | Absolute after 18 degrees |

Stator - Vibration during operation Max. [m/s2] | 300 |

Rotor - Vibration during operation Max. [m/s2] | 300 |

Max. shock during operation [m/s2] | 1000 |

Manufacturer's product ID | AK ERM 2410 EnDat22 |

Availability | Available encoders / Order code (ee) |

|---|---|

M0 | |

8LTA | --- |

8LTB | Yes |

8LTJ | --- |

8LTK | Yes |

8LTQ | --- |

8LTS | --- |

Endat 2.2 Geber

For the advanced, fully digital EnDat 2.2 protocol, the positions are generated directly in the encoder and communicated serially with the drive system. This transfer is very robust in relation to disturbances and is even certified for safety applications.

EnDat 2.2 is therefore to be preferred over the older EnDat 2.1 variant.

Technical data | Encoder type / Order code (ee) | |||||

|---|---|---|---|---|---|---|

E6 | E7 | D0 | D1 | S0 | S1 | |

Operating principle | Optical | |||||

EnDat protocol | 2.1 | 2.2 | ||||

Functional safety1) | --- | Yes | ||||

Single-turn/Multi-turn | S | M | S | M | S | M |

Revolutions | 1 | 4096 | 1 | 4096 | 1 | 4096 |

Resolution [bits single-turn / bits multi-turn] | 13/0 | 13/12 | 25/0 | 25/12 | 25/0 | 25/12 |

Accuracy ±["] | 20 | |||||

Cutoff frequency ≥ [kHz] | 400 | Digital pos. in the encoder | ||||

Stator - Vibration during operation Max. [m/s2] | 300 | |||||

Rotor - Vibration during operation Max. [m/s2] | 300 | |||||

Max. shock during operation [m/s2] | 2000 | |||||

Probability of dangerous failure per hour (PFH) SIL 2 | --- | ≤10 * 10-9 | ||||

Manufacturer's product ID | ECN 1313 | EQN 1325 | ECN 1325 FS | EQN 1337 FS | ECN 1325 FS | EQN 1337 FS |

| 1) | See appendix B "Safety level overview for ACOPOS product family safety functions" of the SafeMOTION user's manual (MAACPMSAFEMC-ENG), which is available in the Downloads section of the B&R website (www.br-automation.com). There are additional limitations when combining B&R motors with a gearbox, see section "1.2.1 ACOPOSmulti SafeMOTION EnDat 2.2 and ACOPOS P3 SafeMOTION" of the SafeMOTION user's manual (MAACPMSAFEMC-ENG), which is available in the Downloads section of the B&R website (www.br-automation.com). |

Availability | Available encoders / Order code (ee) | |||||

|---|---|---|---|---|---|---|

E6 | E7 | D0 | D1 | S0 | S1 | |

8LTA | Yes | Yes | Yes | Yes | Yes | Yes |

8LTB | --- | --- | --- | --- | --- | --- |

8LTJ | Yes | Yes | Yes | Yes | Yes | Yes |

8LTK | --- | --- | --- | --- | --- | --- |

8LTQ | Yes | Yes | Yes | Yes | Yes | Yes |

8LTS | Yes | Yes | Yes | Yes | Yes | Yes |

Nenndrehzahl (nnn)

Nenndrehzahl (nnn)

8LT | b | c | d | . | ee | nnn | ff | gg | - | h | |||||||||||

| Torquemotoren 8LT sind mit verschiedenen Nenndrehzahlen erhältlich. Die Nenndrehzahl wird in Form eines dreistelligen Codes (nnn) als Teil der Bestellnummer angegeben. DrehrichtungHohlwellenmotoren (8LTB / 8LTK) weichen von der üblichen Drehrichtung (rechts) ab und werden linksdrehend ausgeliefert. Eine softwareseitige Anpassung auf rechtsdrehend ist durch den Anwender möglich. |

Bestellcode (nnn) | ||||||

|---|---|---|---|---|---|---|

A08 | 001 | 003 | 005 | 009 | 010 | |

Nenndrehzahl nN [min-1] | 80 | 100 | 300 | 500 | 900 | 1000 |

Verfügbarkeit 8LTx9

verfügbare Nenndrehzahlen nN [min-1] | ||||||

|---|---|---|---|---|---|---|

80 | 100 | 300 | 500 | 900 | 1000 | |

8LTx93 | --- | --- | Ja 1) | Ja 1) | --- | Ja 1) |

8LTx94 | --- | --- | Ja | Ja | --- | Ja |

8LTx95 | --- | --- | Ja | Ja | --- | Ja |

8LTx96 | --- | --- | Ja | Ja | --- | Ja |

8LTx97 | --- | --- | Ja | Ja | Ja 2) | Ja |

8LTx98 | --- | --- | --- | Ja | --- | Ja |

| 1) | für 8LTB / 8LTK nicht erhältlich |

| 2) | für 8LTA / 8LTB / 8LTQ nicht erhältlich |

Verfügbarkeit 8LTxC

verfügbare Nenndrehzahlen nN [min-1] | ||||||

|---|---|---|---|---|---|---|

80 | 100 | 300 | 500 | 900 | 1000 | |

8LTxC3 | Ja | Ja | Ja 1) | Ja 1) | --- | --- |

8LTxC4 | Ja | Ja | Ja | Ja | --- | --- |

8LTxC5 | Ja | Ja | Ja | Ja | --- | --- |

8LTxC6 | Ja | Ja | Ja | Ja | --- | --- |

8LTxC7 | Ja | Ja | Ja | Ja | --- | --- |

8LTxC8 | Ja | Ja | Ja | Ja | --- | --- |

| 1) | für 8LTB / 8LTK nicht erhältlich |

Motoroptionen (ff)

8LT | b | c | d | . | ee | nnn | ff | gg | - | h | |||||||||||

8LT | b | c | d | . | ee | nnn | ff | gg | - | h | Bestellschlüssel | ||||||||||

See the following table for the corresponding code (ff) in the order key.

Motor option | Order code (ff) | ||

|---|---|---|---|

Connection direction | Oil seal | ||

Power connection | Encoder connection | ||

Angled (swivel)  | Angled (swivel)  | --- | F0 |

Yes | F3 | ||

Straight  | --- | F6 | |

Yes | F9 | ||

Anschlussrichtung (ff)

Anschlussrichtung (ff)

Leistungs- und Geberanschluss

8LT torque motors are available with 2 different connection options. The position of the connections is determined by the design of the shaft end.

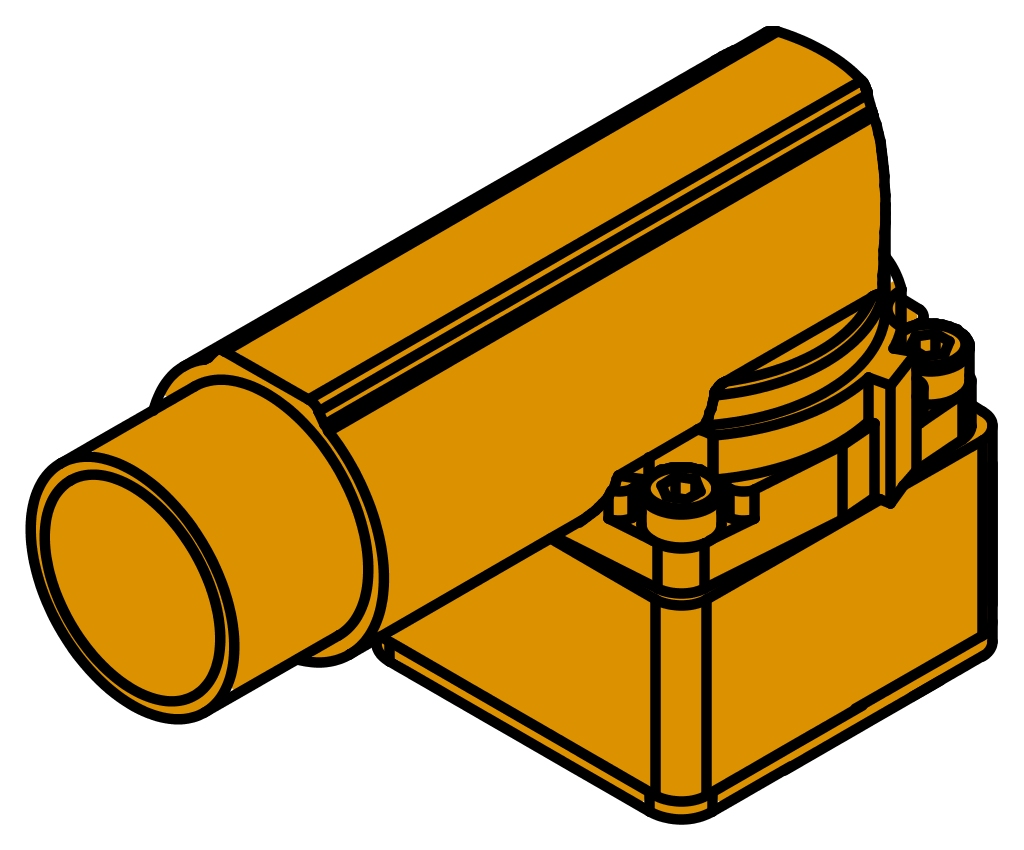

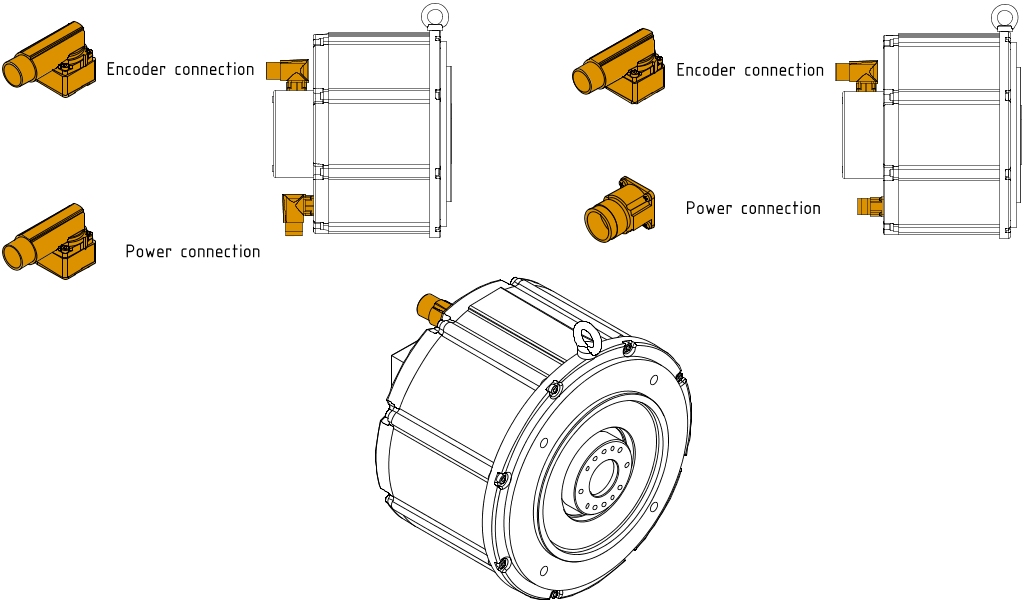

8LTA / 8LTJ / 8LTQ / 8LTS

For motors with ISO output flange or a shaft with blind hole, the connections are at the rear end.

Power connection: Angled (swivel) Encoder connection: Angled (swivel) | Power connection: Straight Encoder connection: Angled (swivel) |

| ||

For details about whether connections can rotate, see the CAD configurator at CAD configurator. | ||

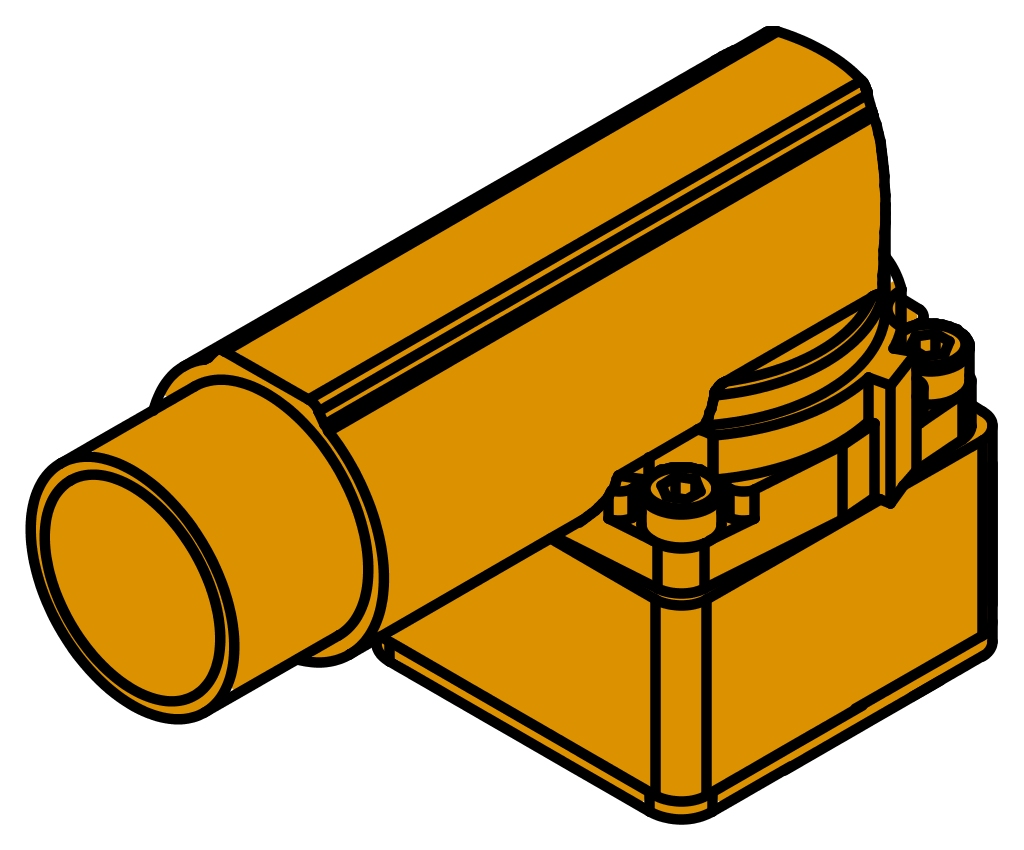

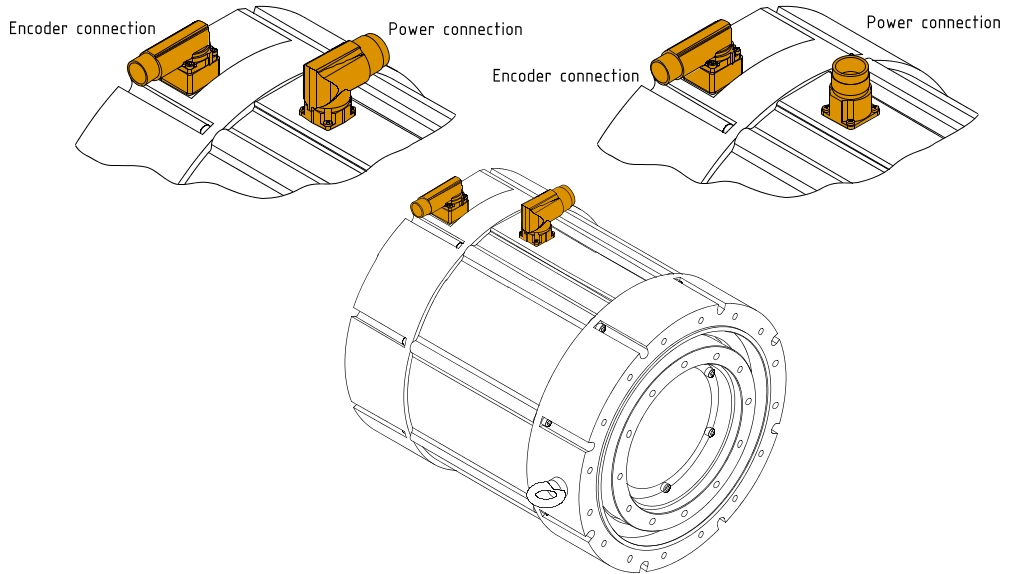

8LTB / 8LTK

Motors with hollow shafts have the connections on the top.

Power connection: Angled (swivel) Encoder connection: Angled (swivel) | Power connection: Straight Encoder connection: Angled (swivel) |

| ||

For details about whether connections can rotate, see the CAD configurator at CAD configurator. | ||

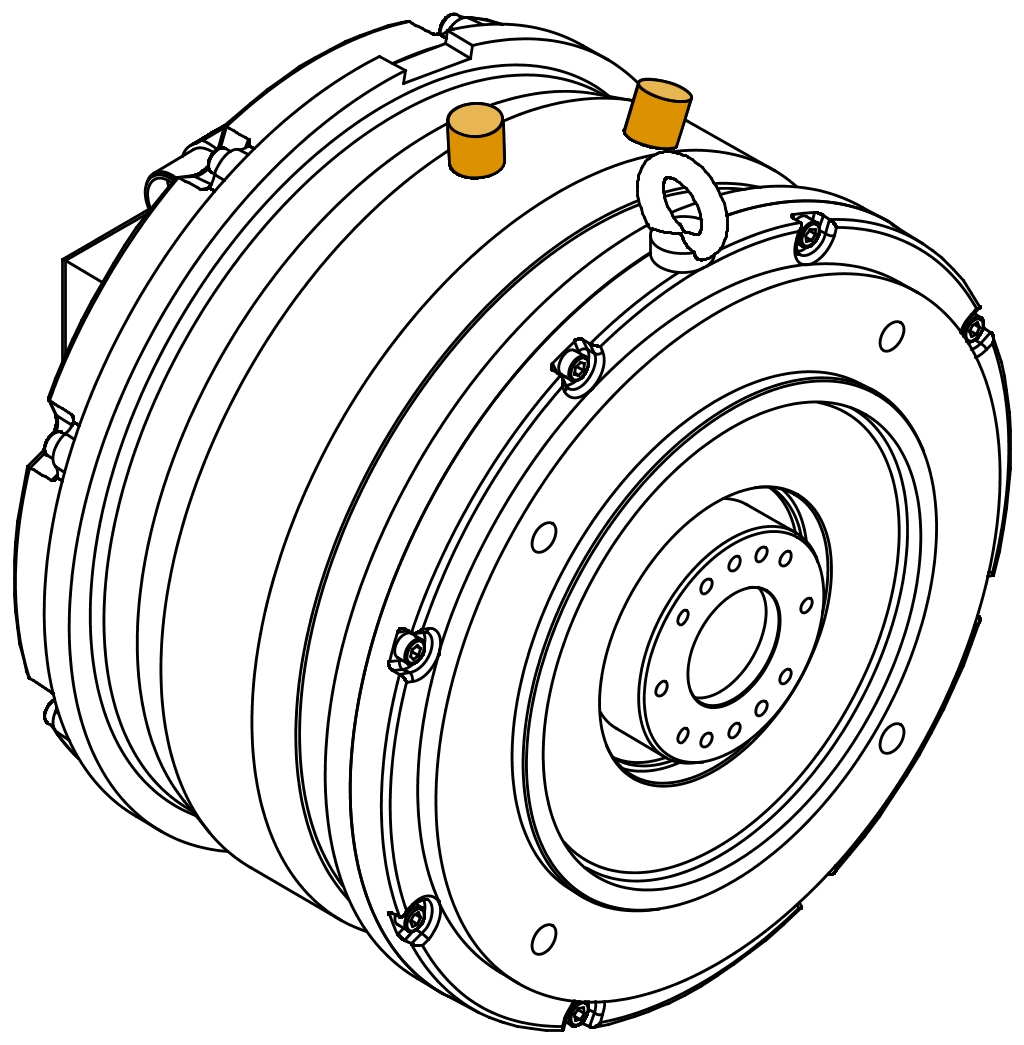

Kühlmittelleitungsanschluss 8LTJ / 8LTK / 8LTS

| ||

The coolant inlet and outlet are straight internal threads (1/4"G). | ||

Wellendichtring (ff)

Wellendichtring (ff)

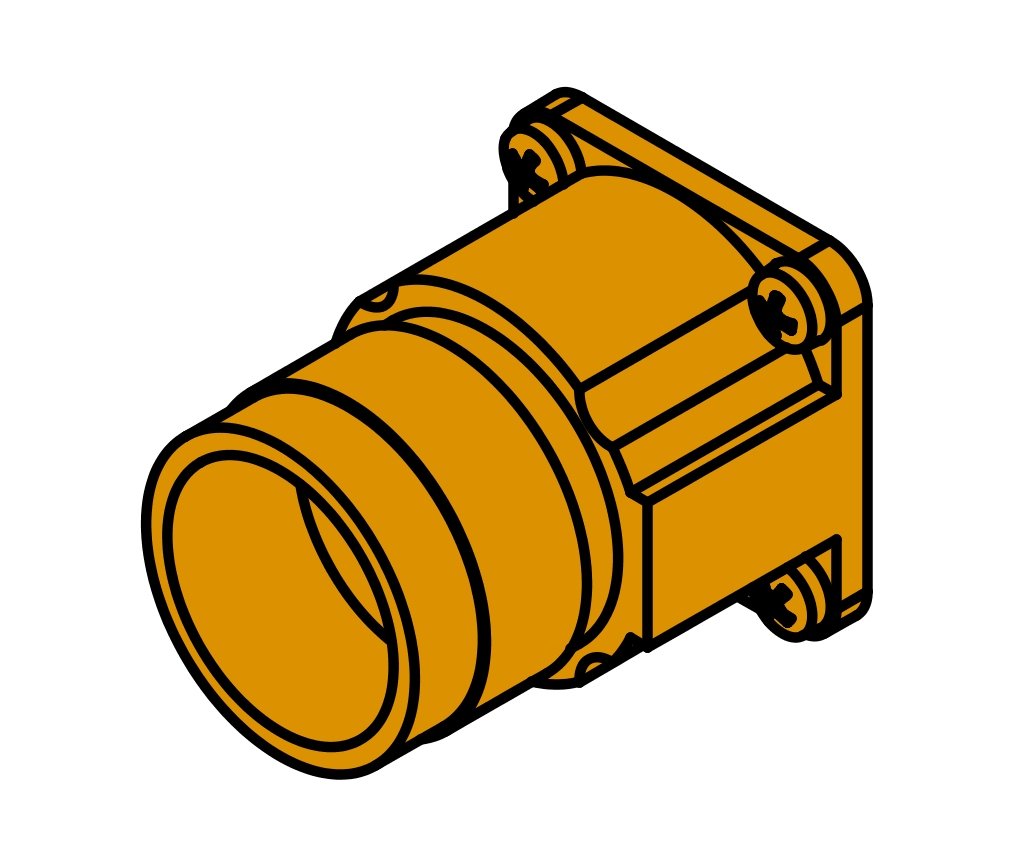

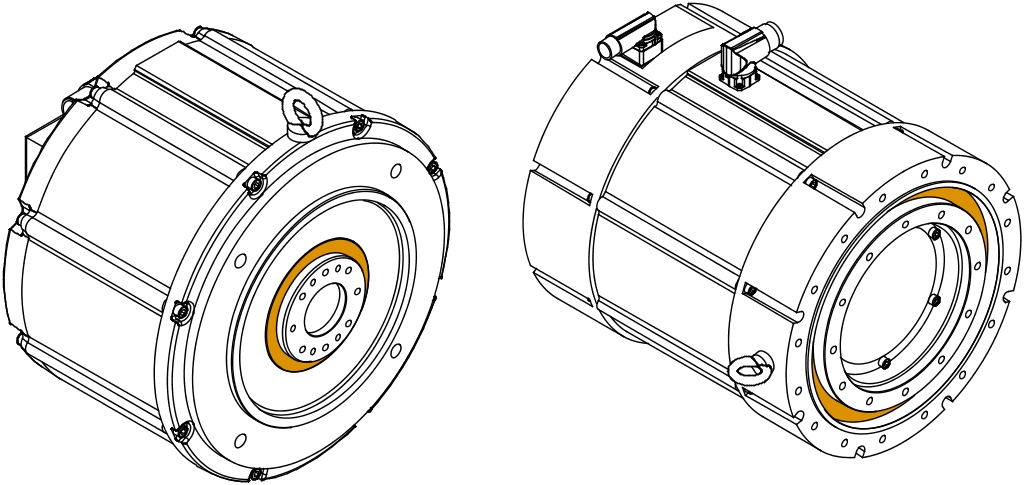

All 8LT torque motors are available with a form A oil seal per DIN 3760.

With an oil seal, the motors have IP65 protection per EN 60034-5.

|

Wartung

Damit die Funktion des Wellendichtringes auf Dauer gewährleistet ist, muss er regelmäßig mit Öl geschmiert werden. Ein nicht geschmierter Wellendichtring verhärtet durch die erhöhte Reibungswärme und kann dann nur noch die Funktion als Staubschutz auf Dauer gewährleisten.

Für eine ausreichende Schmierung des Wellendichtrings ist während der gesamten Lebensdauer des Motors zu sorgen.

Daher ist der Anbau eines Getriebes an Motoren mit Wellendichtring nicht zulässig!

Sondermotoroptionen (gg)

Sondermotoroptionen (gg)

8LT | b | c | d | . | ee | nnn | ff | gg | - | h | |||||||||||

8LT | b | c | d | . | ee | nnn | ff | gg | - | h | |||||||||||

8LT | b | c | d | . | ee | nnn | ff | gg | - | h | |||||||||||

8LT | b | c | d | . | ee | nnn | ff | gg | - | h | |||||||||||

8LT | b | c | d | . | ee | nnn | ff | gg | - | h | |||||||||||

8LT | b | c | d | . | ee | nnn | ff | gg | - | h | |||||||||||

8LT | b | c | d | . | ee | nnn | ff | gg | - | h | |||||||||||

8LT | b | c | d | . | ee | nnn | ff | gg | - | h | |||||||||||

8LT | b | c | d | . | ee | nnn | ff | gg | - | h | |||||||||||

Es sind keine Sondermotoroptionen verfügbar. Gültiger Code (gg) in der Bestellnummer ist 00.

Motorversion (h)

Motorversion (h)

8LT | b | c | d | . | ee | nnn | ff | gg | - | h | |||||||||||

Die Motorversion wird als Code (h) in der Bestellnummer angegeben. Aktuell ist Motorversion 0 gültig.

Bestellbeispiel 1

Bestellbeispiel 1

A torque motor of type 8LSA45 with a nominal speed of 300 rpm has been selected for an application. The motor should have a 2048-line EnDat single-turn encoder. Both the motor and the encoder plugs should be swivel plugs.

The code (ee) for the encoder system is E6.

The code (nnn) for a nominal speed of 300 rpm is 003.

The code (ff) for the other options (connection direction) is F0.

The model number for the required motor is 8LTA93.E6003F000-0

Bestellbeispiel 2

Bestellbeispiel 2

A three-phase synchronous motor of type 8LTJ97 with a nominal speed of 500 rpm has been selected for an application. The motor should have an oil seal and a 2048-line EnDat multi-turn encoder. The motor plug should have a straight connection. The encoder plug should have a "swivel (angled)" connection.

The code (ee) for the encoder system is E7.

The code (nnn) for a nominal speed of 500 rpm is 005.

The code (ff) for the other options (oil seal and connection direction) is F9.

The model number for the required motor is 8LTJ97.E7005F900-0