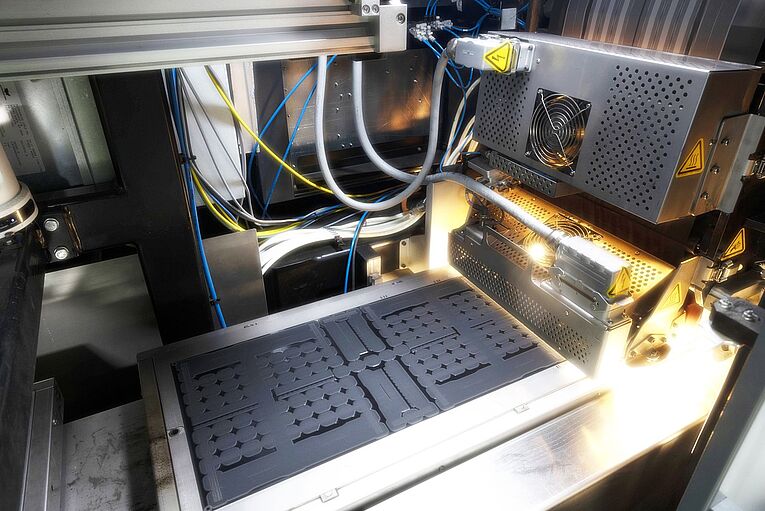

To move the print head along the x and y axes, conventional FFF systems rely on belts, which are subject to deformation, wear and loss of calibration over time. Roboze's beltless system replaces these belts with direct mechatronic movement, making it not only precise, but also highly efficient and easy to maintain. A helical gear ensures smooth movement of the rack and pinion for a significant reduction in noise, wear and localized overheating.

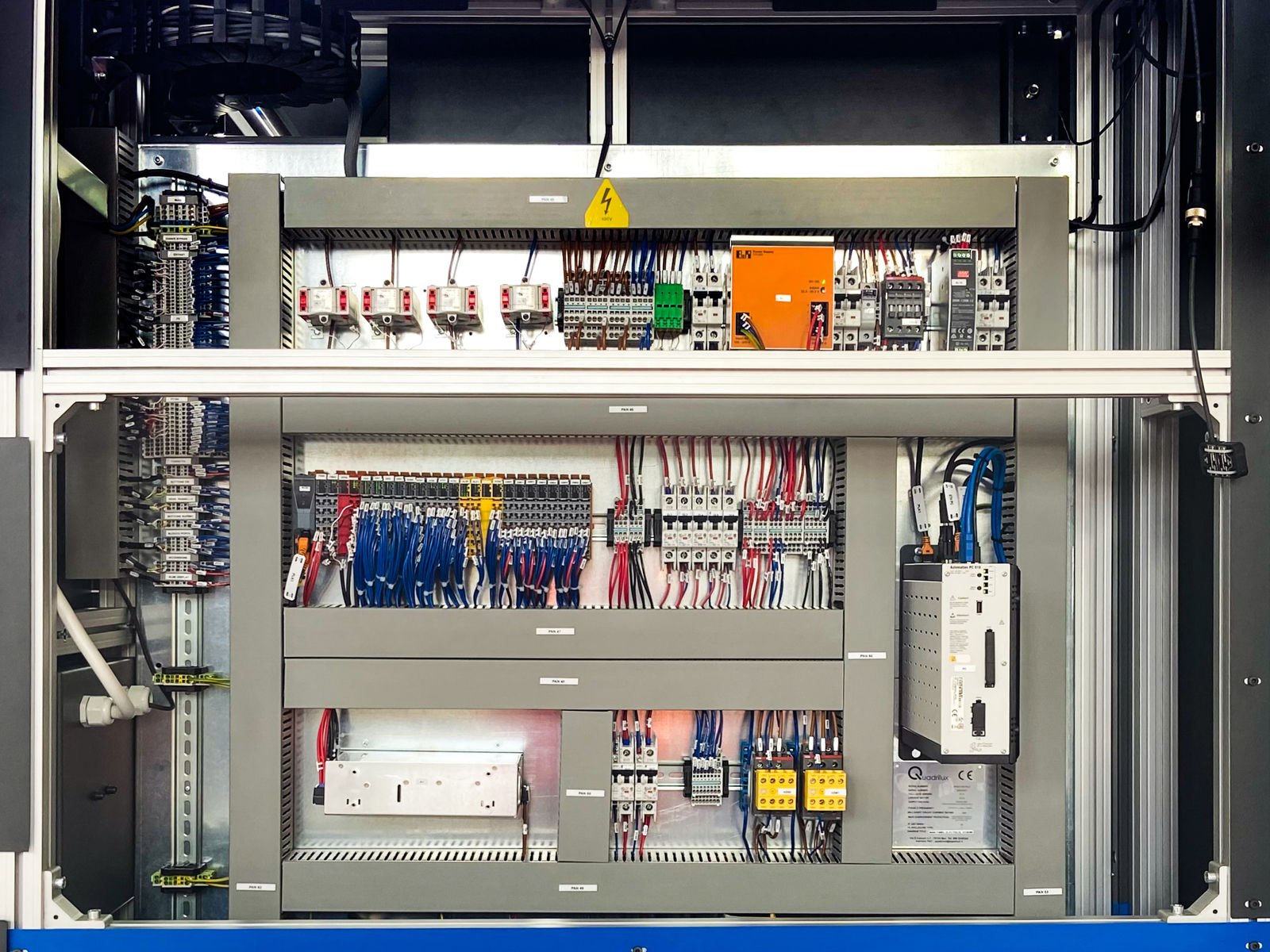

"To compete with a CNC machine, we needed to achieve consistent micrometric tolerances," says Davide Schiena, Roboze's head of application engineering and customer success. The 50-μs sample time of B&R's ACOPOS P3 gave Roboze the performance it needed. "B&R's servo drives help us guarantee a positioning precision of ±10 micrometers," says Schiena. "That's six times better than a belt-driven system."