“The whole is greater than the sum of its parts.” Aristotle's observation certainly rings true for additive manufacturers, and it is demonstrated with particular elegance by the B&R automation system. B&R lives and breathes machine automation, and our solutions reflect that. They provide real value for both machine builders and end-users – every day for the entire life of the machine. Here's what additive manufacturing OEMs are saying will be the critical capabilities their machines must master to take their performance to the next level.

System capabilities

|  |

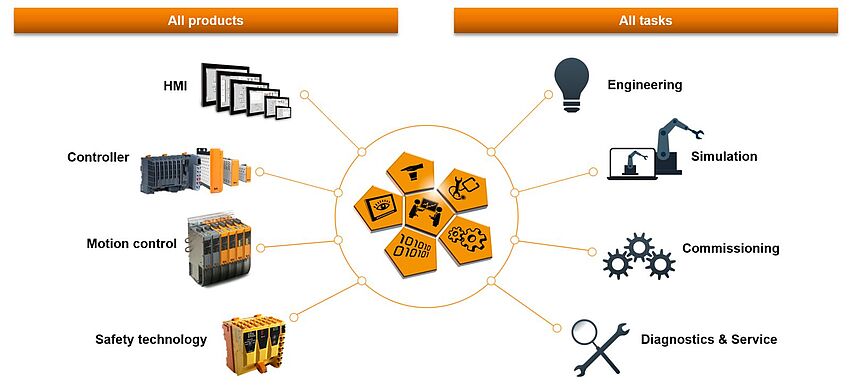

- One integrated tool for all products and tasks: Automation Software

- From design and development to deployment and diagnostics

- Extensive built-in simulation

- Integrated unit testing framework

|  |

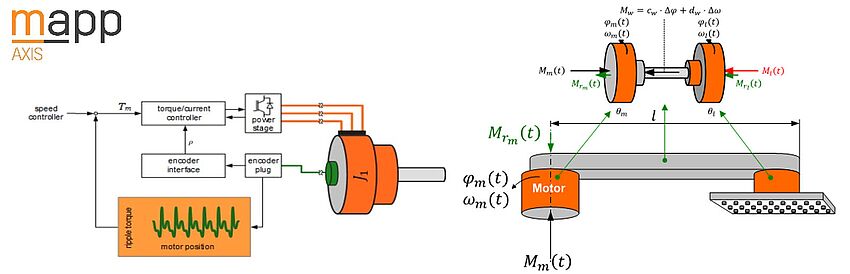

Motion control capabilities

3D printers come in dramatically different sizes. From those that build tiny components like artificial teeth to huge machines with build volumes up to 8 cubic meters.

B&R's broad and scalable range of motion control components has just the right solution for any size printer.

- Oscillation damping for thermally decoupled encoder mounting in high-temperature environments

- Low gantry axis velocity ripple for perfect powder bed flatness

- Special motors with minimized cogging for high-precision printing

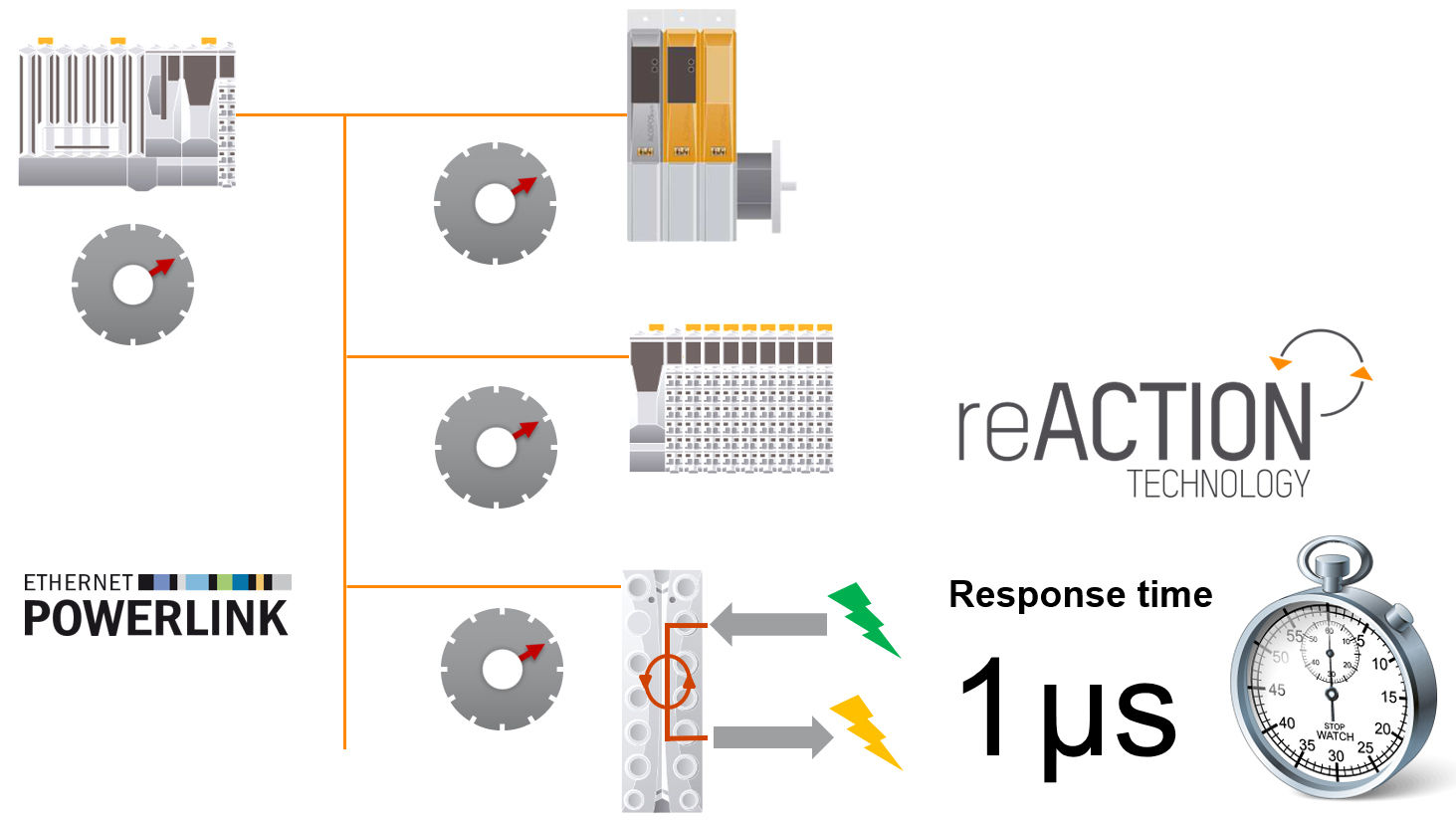

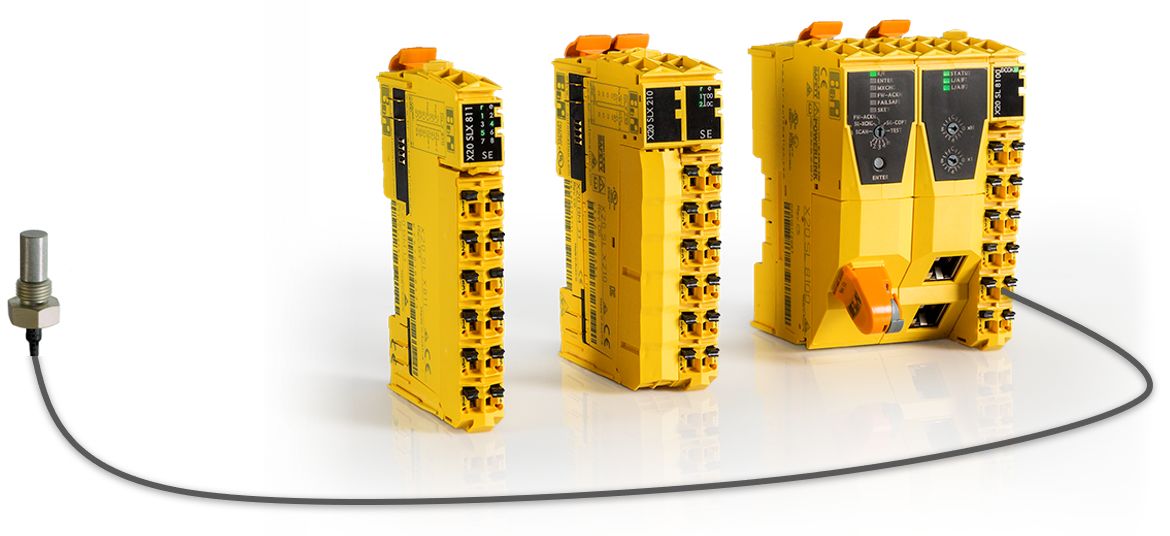

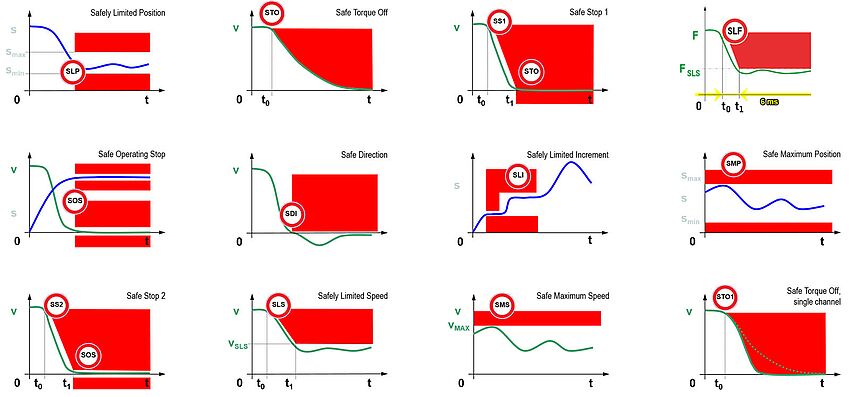

Safety capabilities

|  |

We offer a complete portfolio of safe motion control functions with the industry’s shortest safety reaction time. This guarantees the shortest safety clearances and the smallest machine footprint.

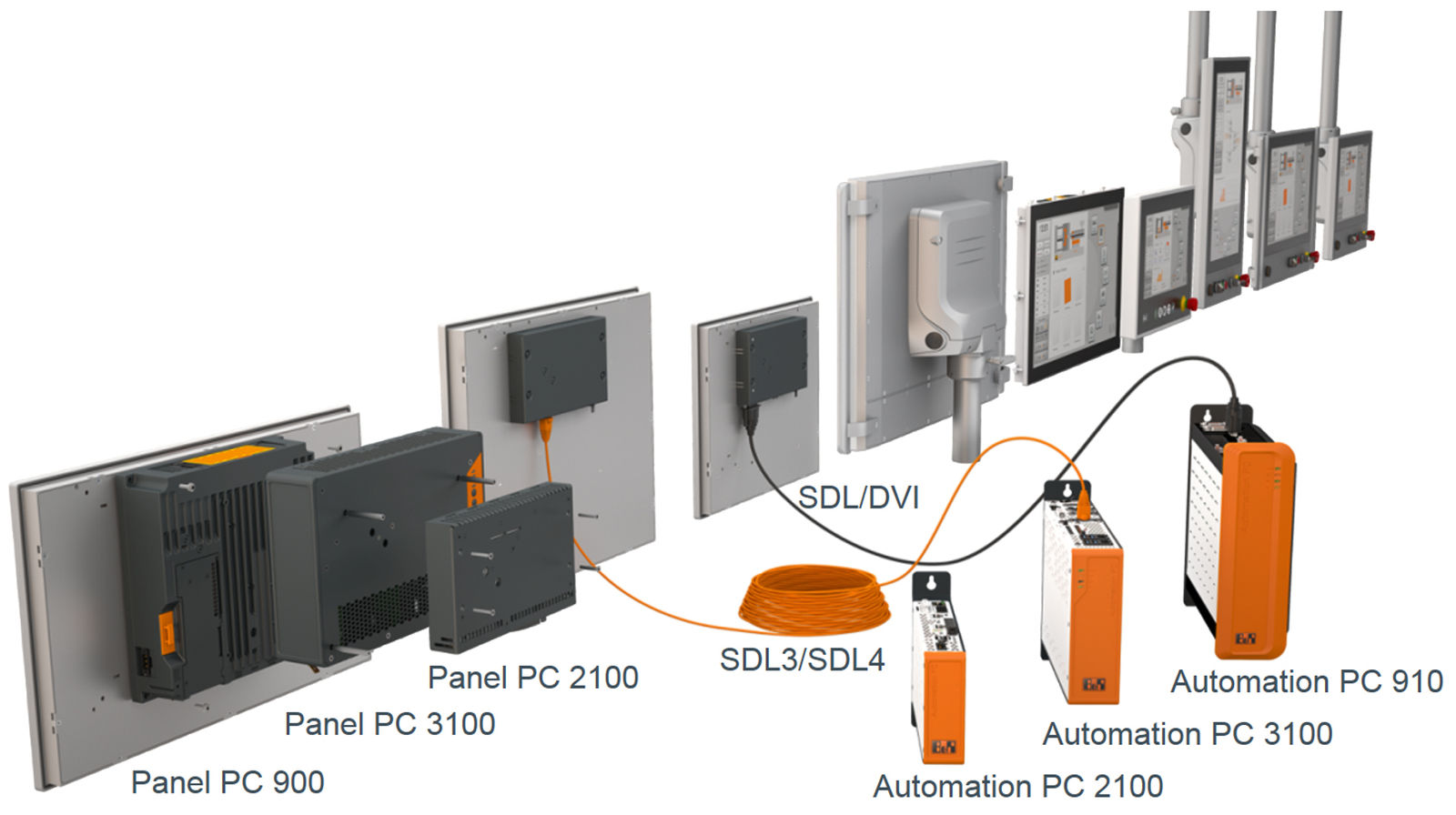

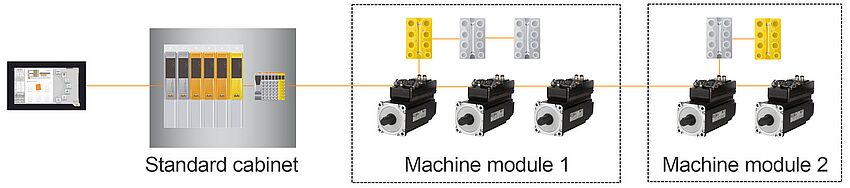

Machine design capabilities

- Cost-efficient options handling with streamlined engineering: Using standardized cabinet for all machine variants and options implemented decentrally

- Significant reduction of cabling: Minimized connections out of cabinet through daily-chaining

- Independent testing of machine units

B&R supports this design approach with IP65 motor-integrated drives and IP67 remote I/O modules designed for out-of-cabinet mounting as well as dedicated support for software modularization in the engineering system.

Floor space is expensive and the trend towards compact machines is universal. B&R’s automation components offer outstanding power density in a highly compact design. |  |