Motoren mit erhöhtem Massenträgheitsmoment

Tipo di raffreddamento/struttura N

Accessori

Drehstrom-Synchronmotoren 8LSN

Vorteile der B&R Servomotoren für Ihre Applikation:

Weitere Informationen

Synchronmotoren 8LSN

Bestellschlüssel 8LSN

Downloads

EU Konformitätserklärung

UK Declaration

UL Certificate of Compliance

Online-Tools

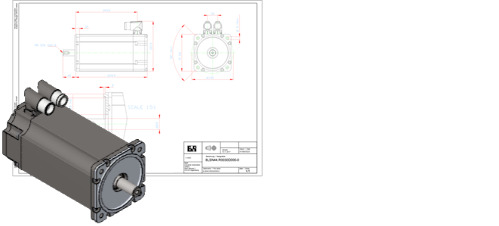

configuratore CAD Per motori e cambi. La nostra applicazione CAD consente di accedere a dati CAD 2D/3D in vari formati.

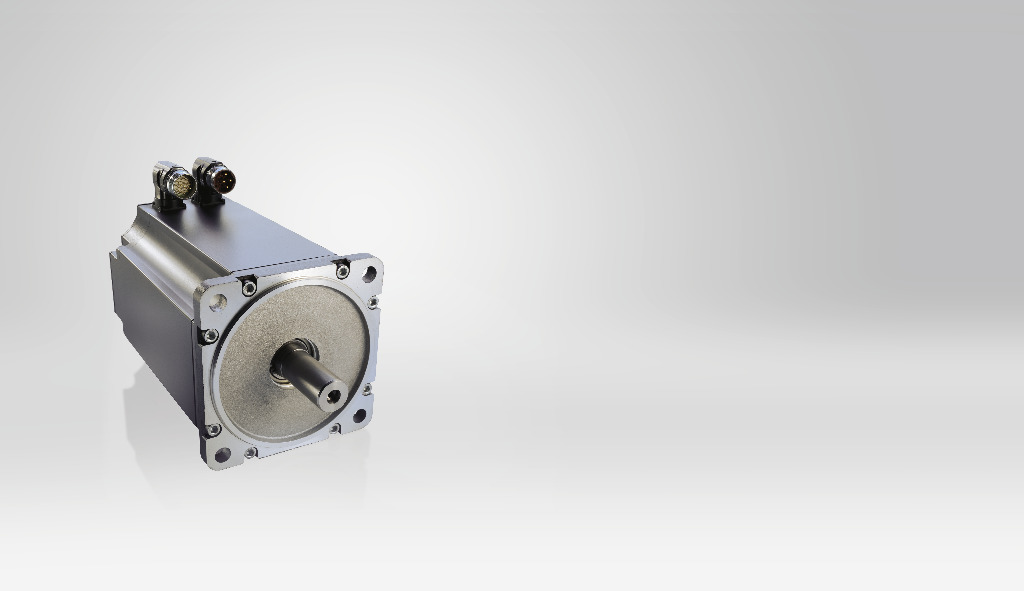

Die glatte Oberfläche

Die glatte Oberfläche

The special surface construction of 8LSN three-phase synchronous motors allows them to be used in applications for the food and beverage industry. Depressions where liquid can collect were deliberately avoided.

Anschlusstechnik

Anschlusstechnik

The uniform connection technology, the pre-assembled cables and the embedded parameter chip allow "plug and play" operation of the power transmission system. The angled connectors can be swiveled, which provides the maximum amount of flexibility during cabling.

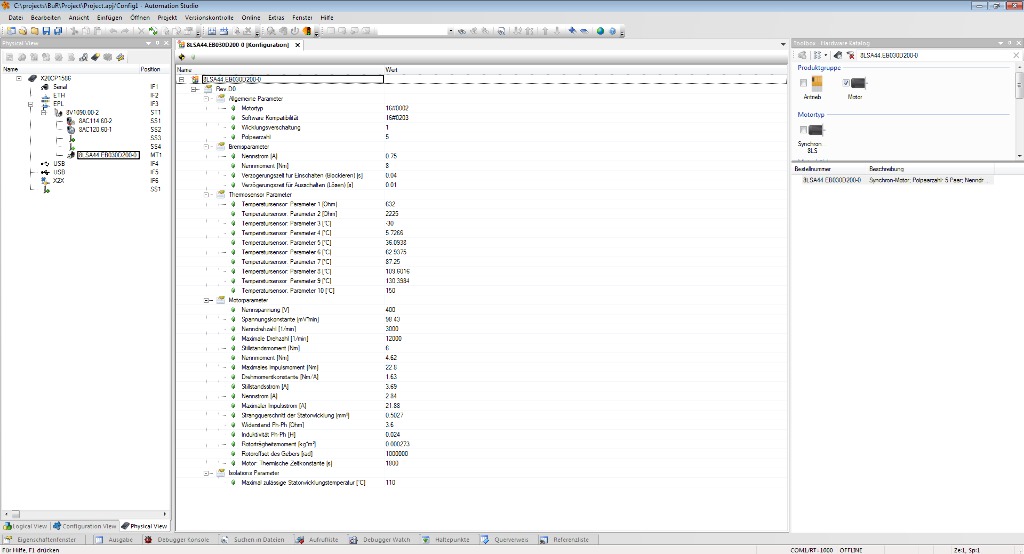

Das elektronische Typenschild

Das elektronische Typenschild

All relevant mechanical and electrical information and data is stored in the EnDat encoder used for 8LSN three-phase synchronous motors. This means that the user doesn't have to configure settings on the servo drive in the field. As soon as the encoder is connected to the servo drive and the power is applied to the electronics, the motor is automatically identified. The motor sends its rated parameters and limit parameters to the servo drive. The drive then automatically determines the current limits and current control parameters required for optimal control of the motor. The user things that the user has to optimize are the speed and position controllers. The integrated commissioning environment in B&R Automation StudioTM provides all necessary support.

In addition to assistance during commissioning, routine service work is also simplified, and motors can be exchanged without having to take extra time to set parameters.

Kühlarten/ Bauform

Kühlarten/ Bauform

8LSN three-phase synchronous motors are self-cooling and have a long, slim design. The motors must be installed on the cooling surface (flange).

Baugrößen

Baugrößen

8LSN three-phase synchronous motors are available in 2 different sizes (4, 5). They have different dimensions (especially flange dimensions) and power ratings. These different sizes are indicated by a number represented by (c) in the model number. The larger the number, the larger the flange dimensions and power rating for the respective motor.

Cooling type | Available sizes | |

|---|---|---|

4 | 5 | |

A | Yes | Yes |

Baulängen

Baulängen

The 8LSN three-phase synchronous motors are available in up to 5 different lengths. They have different power ratings with identical flange dimensions. These different lengths are indicated by a number represented by (d) in the model number.

Length | Available sizes | |

|---|---|---|

4 | 5 | |

3 | Yes | - |

4 | Yes | Yes |

5 | Yes | Yes |

6 | Yes | Yes |

7 | - | Yes |

8 | - | Yes |

Rückführungssysteme nach Maß

Rückführungssysteme nach Maß

8LSN three-phase synchronous motors are available with different encoder systems. As standard, they are equipped with Heidenhain EnDat encoders. Depending on the application, the customer can select between normal and high-resolution encoders. Both types are also available as multi-turn encoders. They allow operation without requiring homing procedures or additional measurement systems on the workpiece. The absolute encoder functions without a battery and is therefore absolutely maintenance free. 8LSN three-phase synchronous motors are also available with resolvers for machines with lower precision and speed requirements.

Belastbarkeit des Wellenendes und der Lagerung

Belastbarkeit des Wellenendes und der Lagerung

8LSN three-phase synchronous motors are equipped with grooved ball bearings which are sealed on both sides and greased. Radial and axial forces (Fr, Fa) applied to the shaft end during operation and installation must be within the specifications listed below. Bearing elements may not be subjected to shocks or impacts! Incorrect handling will reduce the service life and result in damage to the bearings.

The axial forces Fa permitted during the installation of pinion gears, couplings, etc. depend on the motor size and can be found in the following table:

Motor size | Permissible axial force Fa [N] |

|---|---|

Standard bearing | |

4 | 2300 |

5 | 2500 |

The radial force Fr on the shaft end is a function of the loads during installation (e.g. belt tension on pulleys) and operation (e.g. load torque on the pinion). The maximum radial force Fr depends on the shaft end type, bearing type, average speed, the position where the radial force is applied and the desired service life of the bearings.

The axial force Fa on the shaft end is a function of the loads during installation (e.g. stress caused by mounting) and operation (e.g. thrust caused by slanted tooth pinions). The maximum axial force Fa depends on the bearing type and the desired service life of the bearings. The fixed bearing is secured on the A flange with a retaining ring. The floating bearing is preloaded on the B flange with a spring in the direction of the A flange. Axial forces in the direction of the B flange can cause the spring bias to be overcome and the shaft is shifted by the amount of axial play in the bearing (approx. 0.1 - 0.2 mm). This shift can cause problems on motors with holding brakes or motors with EnDat encoders (EA and EB). As a result, no axial force is permitted in the direction of the B flange when using these motors.

Axial loads are not permitted on shaft ends of motors with holding brakes. It is especially important to prevent axial forces in the direction of the B flange since these forces can cause the brake to fail!

Information for determining permissible values of Fr and Fa can be found in the motor data for the respective three-phase synchronous motor. Permissible values are based on a bearing lifespan of 20,000 h (bearing lifespan calculation based on DIN ISO 281).

Motoroptionen

Motoroptionen

8LSN three-phase synchronous motors are available

- With various rated speeds

- With or without an oil seal

- With or without a holding brake

- With a smooth or keyed shaft

- With two different connection directions

.

The rated speed is listed as part of the model number in the form of a 3-digit code (nnn). This code represents the nominal speed divided by 100. The respective combination of other motor options is listed in the form of a 2-digit code (ff) as part of the model number.