Use case: My smoothie

Many smoothie fans already use the Internet to search for creative new recipes. But then, they resort to the time-consuming and often messy approach of going out and buying the ingredients, taking them home and pureeing them. The faster, easier way to get the ultimate smoothie experience is to order your preferred mix online – say 60% banana, 20% cherry, 10% pineapple and 10% kiwi – and have your custom smoothie delivered straight to your door. And, what if you could also pick the color of the cap and the design on the label? Many experienced producers would call this wishful thinking. After all, until now it has hardly been possible to make personalized products in a way that is profitable.

More flexible manufacturing

In traditional mass production, conveyor belts carry products at fixed intervals and constant speed through a variety of processing stations before they are packaged for sale. This approach no longer meets the needs of today's consumers. The young generation of digital natives enjoy the ability to express their individuality through products tailored to their needs and preferences – and they are willing to pay a premium for them. To address this market and remain competitive, manufacturers are challenged to make their production lines more flexible.

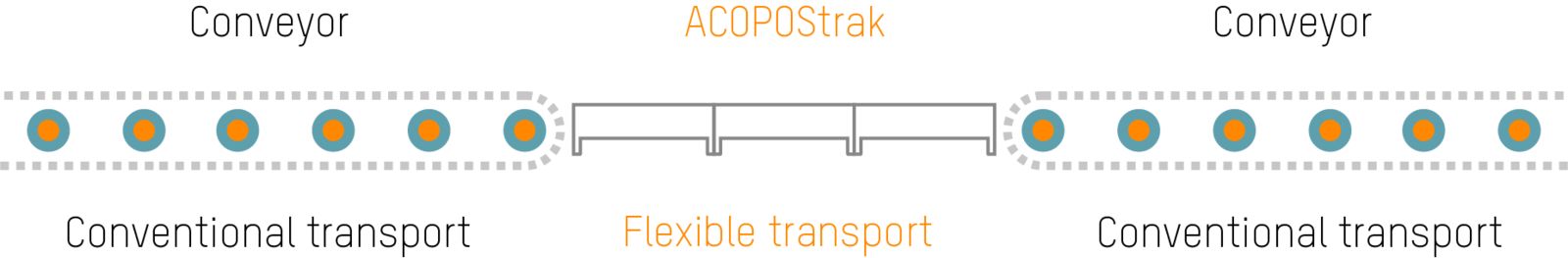

So, how can it be done? One way is to replace conventional conveyor belts with intelligent track-based transport systems. In some cases, however, it's not necessary to do so for the entire line. That's why B&R designed its intelligent ACOPOStrak transport system to interact perfectly with conventional conveyor belts. Many times, all you need to make a personalized product is one short section of flexible, intelligent, track-based transport. The products can be carried through the rest of the line as usual. Such a hybrid approach combines the flexibility of the intelligent track with the low cost of conventional belts.

Easy hand-off

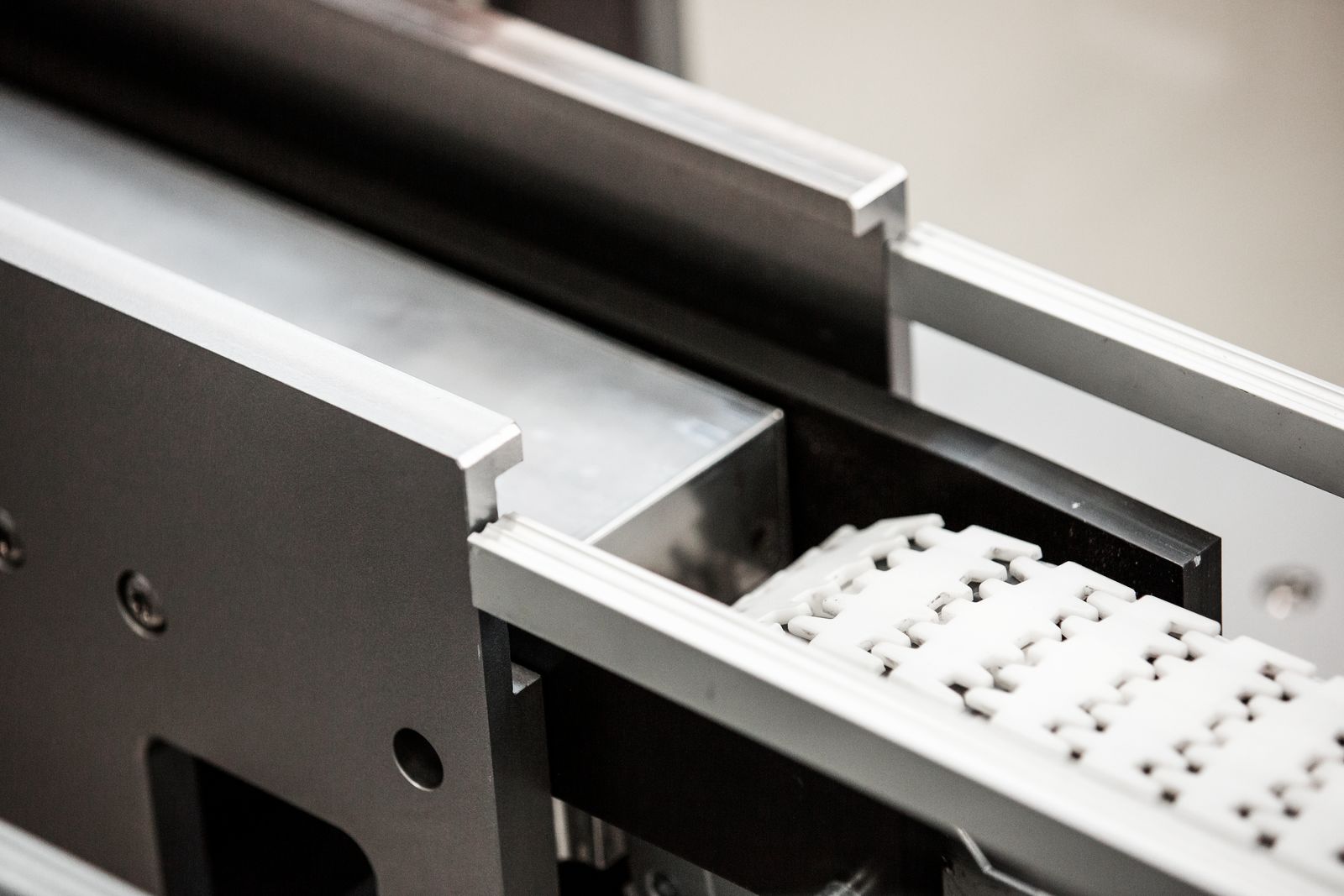

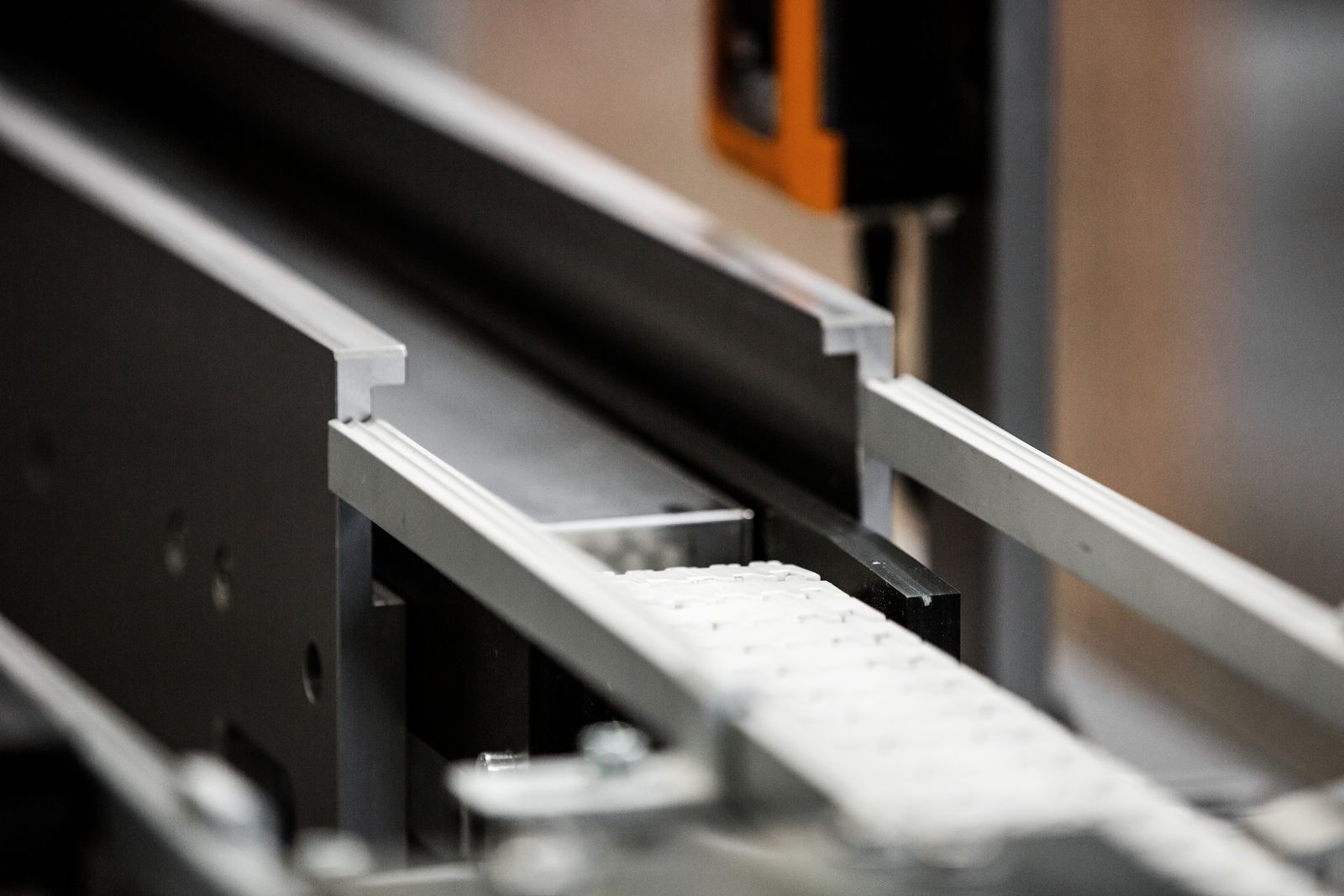

In some cases, this makes a hybrid solution the most cost-efficient response to the needs of flexible manufacturing. The key is being able to transfer the products between systems without assistance from an operator or robot. With B&R's solution, this is made possible by the special construction of the shuttles. They are held on the track by magnetic force and on the conveyor belt by friction. Continuous guide rails keep them on the right path.

While the conveyor belt moves the products with constant speed and spacing, each shuttle on the ACOPOStrak segment can be controlled independently. With the rigid timing of the conveyor belt no longer in effect, batch-of-one personalization can begin.

It becomes easy to vary transport speed and processing times. Integrating just a short segment of ACOPOStrak into a conveyor system adds the flexibility needed for profitable mass customization. Producers are finally free to explore the endless possibilities of personalization.

Cost-effective solution also saves space

ACOPOStrak's modular design allows segments of different lengths to be integrated into conventional conveyor systems. For a 100-meter-long production line that only needs 10 meters of intelligent transport, that leaves 90 meters of conventional conveyor.

Each ACOPOStrak segment has an integrated drive assembly. The power electronics and a powerful processor are built into the motor. There is no need for any additional inverters or motion control units, which would not only add substantial cost, but consume a great deal of space in the control cabinet. As a result, the combination of ACOPOStrak and conveyor belts is a very compact, space-saving solution.

Hybrid solutions significantly expand the range of potential ACOPOStrak applications. Many lines could benefit from greater flexibility, and achieving it will now be economically feasible.

More information about ACOPOStrak