With the APROL process control system, biogas system manufacturers have the perfect solution for controlling the entire process. Because of its excellent scalability, APROL can be operated inexpensively on an industrial PC and offers redundancy solutions, safety technology and fully integrated drive solutions.

B&R technology in action

A new law for biogas plants has changed the market as it was. Faced with just such a situation, one manufacturer of biogas plants saw an opportunity to change control systems. The project began with specifications listing over 100 requirements and a tightly calculated budget.

B&R has the perfect solution for...

SCADA and process control systems

The APROL process control system is mainly characterized by universal use. This is due to its unique scalability, modularity and flexibility.

As a reliable solution in over 3000 installations in the field, it offers the following important features:

- Openness through a large number of standardized interfaces for connecting field devices, lower level or higher level systems

- Secure data transfer

- Manipulation-proof data storage

- Audit Trail FDA conformity (traceability of all changes)

- Generating alarms

- Trend system (implemented using a database)

- Integrated business intelligence solution

- Further information:

- APROL Process Automation brochures

High-performance industrial PCs

Powerful

Automation PC and Panel PC systems from B&R pack plenty of power. Using the latest technology, including the latest generation of Intel Core i-series processors, the Automation PC 910 and Panel PC 900 are the perfect choice for mastering highly demanding applications. The Automation PC 2100 and Panel PC 2100 are based on the latest Intel Atom technology. These systems have minimal size, but can deliver performance up to the Core i-series range.

Energy efficient

Another advantage of the latest generation of Core i-series and Atom processors from Intel is their considerably higher performance yet lower power consumption – maximized energy efficiency across the board. This makes it possible to do away with internal fans in many cases, an advantage already exploited by the passively cooled Automation PC 2100 and Panel PC 2100 systems.

Rugged

The robust design of the Automation PC and Panel PC is perfectly suited for operation in the harshest environments – even continuous 24-hour operation is no problem for these workhorses. Many variants of the PC systems have no internal cable connections whatsoever, let alone rotating parts.

Reliable

Each PC and panel undergoes comprehensive function testing prior to shipping. All system properties and interfaces are fully inspected. After years of reliable operation, your bottom line will notice the difference.

Customized

Automation PCs can be adapted perfectly to each application's unique requirements. This starts by selecting the necessary processor performance and housing size from within the series and then scaling everything else – memory capacity and storage media such as CFast, HDD or SSD, for example – as needed.

Ready to use

These industrial PCs are delivered completely ready to use. OEM machine manufacturers can have the Automation PC sent directly to their control cabinet supplier with all software fully installed. Upon request, B&R can freeze versions of BIOS and firmware for guaranteed long-term consistency – a huge advantage for individually certified machines and systems.

Long-term availability

Both the Automation PC 910 and Panel PC 900 as well as the Automation PC 2100 and Panel PC 2100 will be available over the long haul. Once the PC has been integrated into a machine, no additional maintenance work is necessary for the machine manufacturer. The machine enters series production and can continue to be manufactured for over a decade.

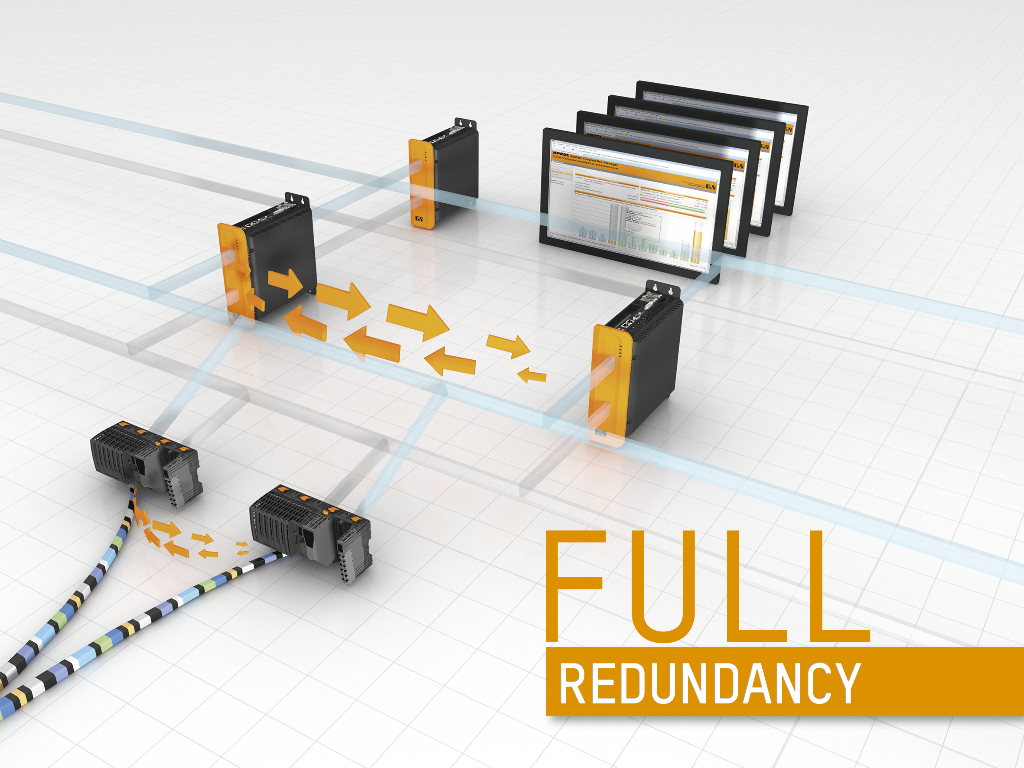

Redundancy

Increased availability through redundancy is a fundamental building block of energy technology. With its flexible product portfolio, B&R offers an efficient solution that can meet all demands.

- Server redundancy on B&R's APROL process control system

- Runtime Server

- Operator stations

- Hot / standby server redundancy

- Standard X20 controllers

- Extremely fast switchover times down to under a millisecond

- Bumpless changeover

- Network redundancy

- Various fieldbus systems are available

- Media and cable redundancy

- Ring redundancy

- Supply redundancy

- Redundant 24 V power supply modules

- Redundant power supplies

- Further information:

- Details concerning redundancy

- User's manual: Redundancy for control systems

- Details concerning the X20 system

- Details concerning the power supply

Groundbreaking safety technology

The B&R safety system provides a clear technological advantage with the highest level of safety and allows intelligent safety concepts to be implemented that would otherwise not be possible. The safety system is completely integrated into the standard (non-safety) control system and fully transparent.

Simple programming

Safety applications are created with pre-certified function blocks using a safe, integrated development tool. FBD and Structured Text programming languages are available for this purpose. In addition, there will also be the opportunity to create function blocks independently, for example in ANSI-C.

Remote maintenance and acknowledgment

An open interface for remote acknowledgment of errors and service scenarios is also available in addition to a remote update function for the safety application.

Comprehensive product portfolio

Various functions and different variants exist that can be used for all types of applications: IP20, IP20 coated or IP67 protection available:

- Digital inputs

- Digital outputs (0.5 A, 2 A and 10 A)

- Relay outputs

- Switching potential groups

- Counter module detecting pulses

- Analog inputs

- Temperature inputs (PT100/1000 and temperature sensors)

- Further information:

- Details concerning safety technology

- Integrated safety technology brochures

Integrated Motion Control

As an expert in drive technology, B&R offers a very wide range of drive units: From compact, single-axis, multi-axis or motor-mounted servo drives to frequency converters.

Uniform control with Generic Motion Control

All drive technology components are integrated seamlessly into the Automation Studio development tool. Regardless of the drive and motor being used, all functions are available – from single-axis movements to CNC and robotics.

Simple solutions for complex control systems

Even the most complex control system requirements can be easily met using B&R drive technology. With technology packages for various solutions and an extensive standard library, any task can be solved in an efficient manner.

- Further information:

- Hareket Kontrolü

- System overview - Drive systems

- System overview - Frequency inverters

- System overview - Motor systems