Individual elements, such as turbine controllers and complete control systems for hydroelectric power plants, can be easily implemented using the APROL process control system.

Controllers can be developed very efficiently, for example using MATLAB/Simulink or MapleSim, and can be made available at the push of a button.

B&R utilizes open standards in all products and thus provides investment security for decades to come.

B&R has the perfect solution for...

SCADA and process control systems

The APROL process control system is mainly characterized by universal use. This is due to its unique scalability, modularity and flexibility.

As a reliable solution in over 3000 installations in the field, it offers the following important features:

- Openness through a large number of standardized interfaces for connecting field devices, lower level or higher level systems

- Secure data transfer

- Manipulation-proof data storage

- Audit Trail FDA conformity (traceability of all changes)

- Generating alarms

- Trend system (implemented using a database)

- Integrated business intelligence solution

- Further information:

- APROL Process Automation brochures

Automatic code generation

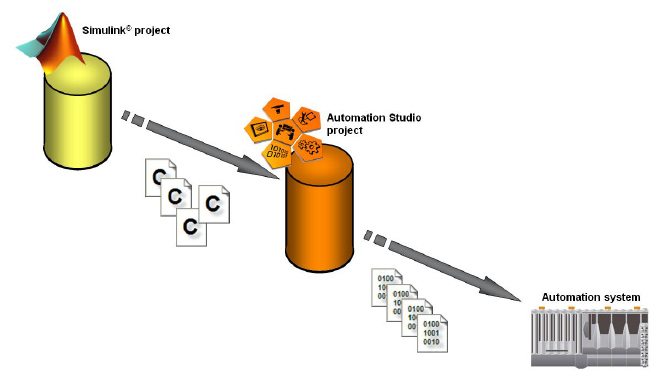

Algorithms and control loops developed in specialized tools can be very quickly and accurately implemented in control programs with automatic code generation. B&R offers a number of certified interfaces e.g. to MATLAB/Simulink or MapleSim.

The interface to Simulink is very simple to use. The input/output variables on the controller are simply defined in Simulink. The full power of Simulink is then available to the control program and also the controller component.

- Further information:

- Details concerning the Simulink interface

Open standards

The only future-proof solution is an open solution. Openness allows you to work with the tools you are most comfortable using. It allows machines to communicate effortlessly with external systems, and by facilitating the reuse of existing software for future solutions, it frees up valuable time to get your product to market faster. B&R offers openness on all levels and in all products.

High-precision turbine speed measurement

A critical measurement value for each turbine is the rotational speed. The associated controller must be able to react very quickly and precisely to any change in speed. With ultra-fast application cycle times of 1 µs, reACTION technology has proved to be especially well-suited for these types of applications because the measurements, the pre-processing and when necessary the reaction can be implemented directly in the I/O module.

- reACTION technology stands for:

- Ultrafast I/O responses

- For both low-end and high-end systems

- Fully integrated

- Open IEC 61131 technology

- Centralized software management

- Decentralized program execution

- Further information:

- reACTION Teknolojisi

- Ultrafast automation brochure

Robust control platform

B&R's proven X20 system is characterized by the fact that it can be adapted to any application due to its thinness, modularity and flexibility.

Huge product portfolio, all fieldbus systems

More than 250 different X20 modules allow use in any conceivable application. Interfaces to all the relevant fieldbus systems are available for integrating and connecting the X20 system with various sensors, systems, etc.

Approved for maritime use and an extended temperature range

Nearly all standard system components are certified for maritime applications. This permits their use on ships or offshore and is a seal of quality for the products due to the strict testing that must be carried out. The X20 system offers, with only a few exceptions, a continuous operating temperature range from -25 to +60°C.

Heavy duty construction

In addition to products with IP20 protection, there is also a coated version of the system available that can withstand up to 100% humidity and corrosive gases as well as the X67 system for applications that require IP67 protection.

- Further information:

- Details concerning control systems

- X20 System Overview

- X67 System Overview

- Details concerning certifications

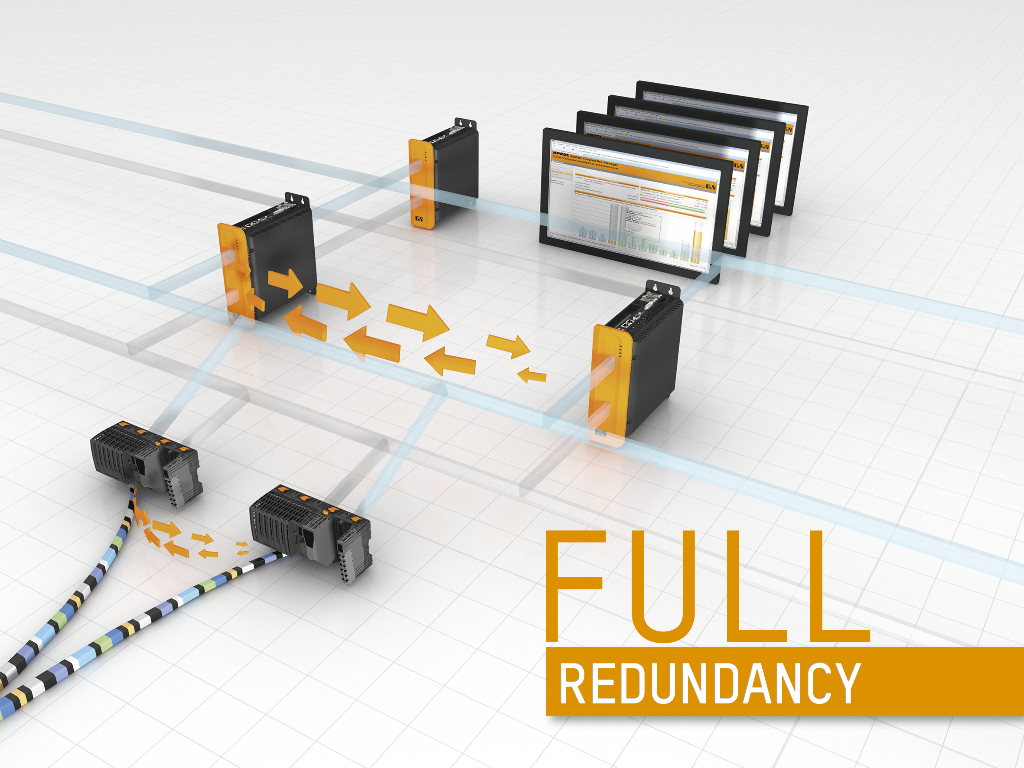

Redundancy

Increased availability through redundancy is a fundamental building block of energy technology. With its flexible product portfolio, B&R offers an efficient solution that can meet all demands.

- Server redundancy on B&R's APROL process control system

- Runtime Server

- Operator stations

- Hot / standby server redundancy

- Standard X20 controllers

- Extremely fast switchover times down to under a millisecond

- Bumpless changeover

- Network redundancy

- Various fieldbus systems are available

- Media and cable redundancy

- Ring redundancy

- Supply redundancy

- Redundant 24 V power supply modules

- Redundant power supplies

- Further information:

- Details concerning redundancy

- User's manual: Redundancy for control systems

- Details concerning the X20 system

- Details concerning the power supply