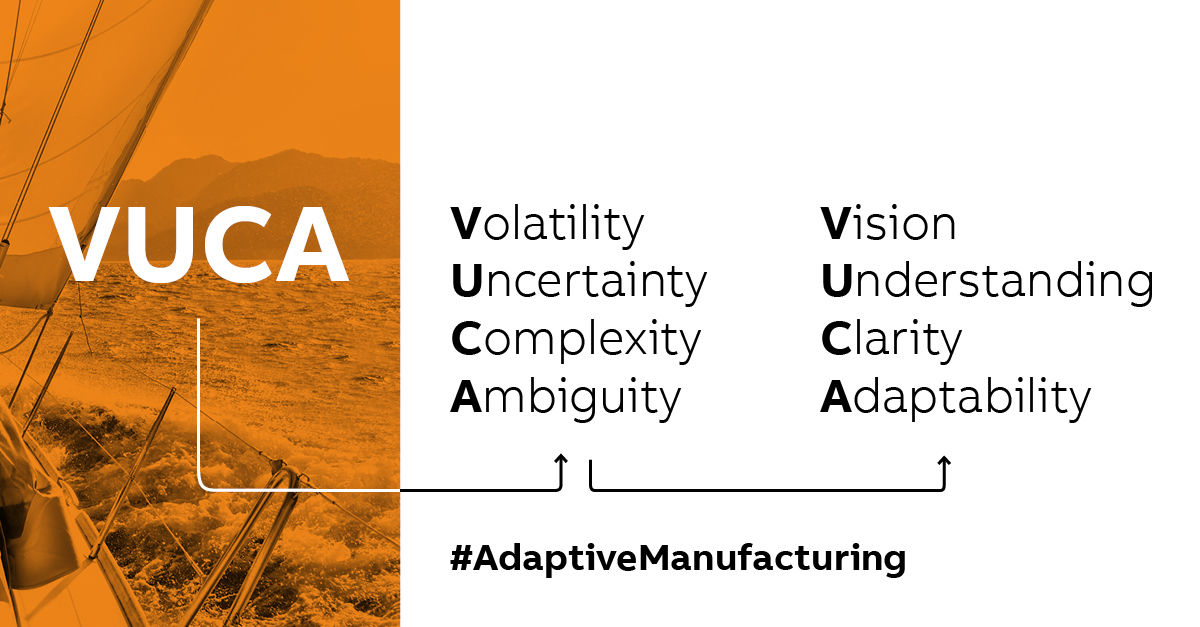

For much of its history, industrial manufacturing has been all about productivity and economies of scale. You could enjoy many years of success with a small number of products, simply by scaling up volume and improving efficiency. More recently, however, e-commerce began conditioning consumers to expect faster and faster delivery of increasingly personalized products. And as social media trends come and go, sudden changes in demand become more and more common.

Then, along came a global pandemic. Stay-at-home orders propelled e-commerce forward by years virtually overnight. Online and direct-to-consumer (D2C) sales doubled and tripled, and companies pivoted business models on the spot to survive. Now, even as stores reopen, the share of consumers who purchase most or all of their products online remains elevated. Consumer behavior has shifted, and there is no going back.

But consumer behavior is not the only area where recent crises have catalyzed existing trends. The dramatic global impact of localized lockdowns and port closures has highlighted the risk of supply chain disruptions and accelerated the trend toward reshoring and nearshoring. Even more momentum has been added as geopolitical conflicts impact fuel and freight costs, and climate change drives efforts to improve sustainability.