B&R's user management system allows custom configurations for each operator. The new Diagnostics function now allows the operator to choose via the HMI terminal how detailed the process flow diagnostics should be. This helps minimize downtime and significantly increases plant availability.

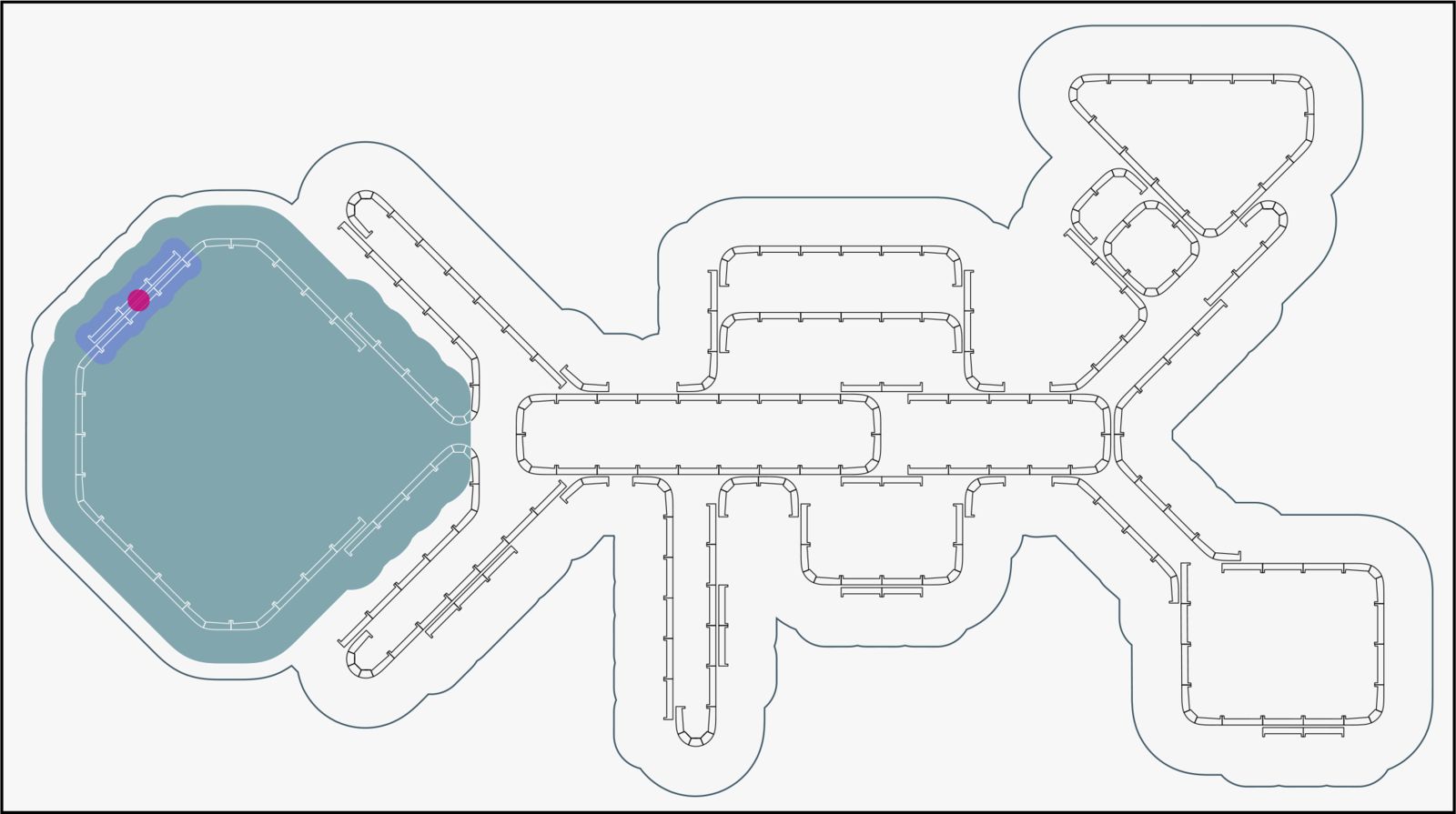

Diagnostics can be used to analyze the process flow of an entire plant at a macro level. Throughput analyses can identify potential traffic jams or disruptions.

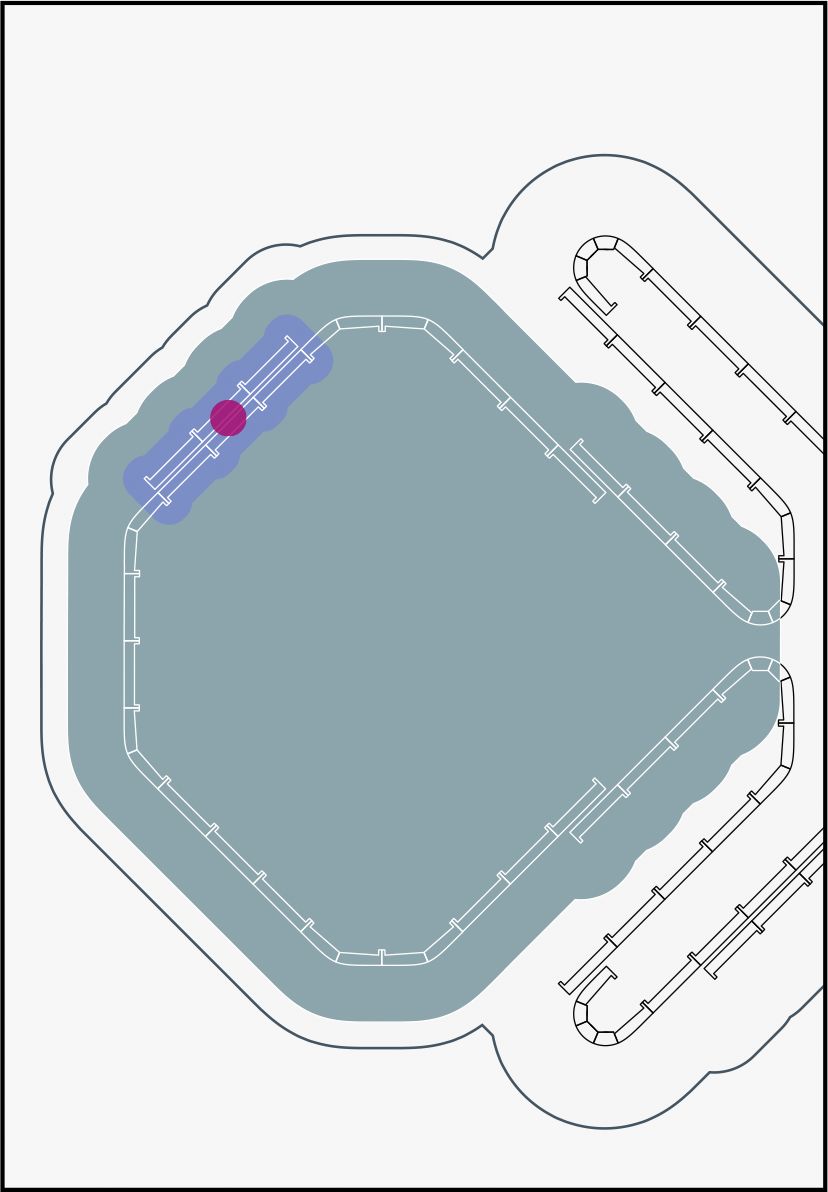

An intermediate level provides an additional degree of detail. Here, diagnostics are applied to individual modules or track segments to narrow down where delays are occurring.

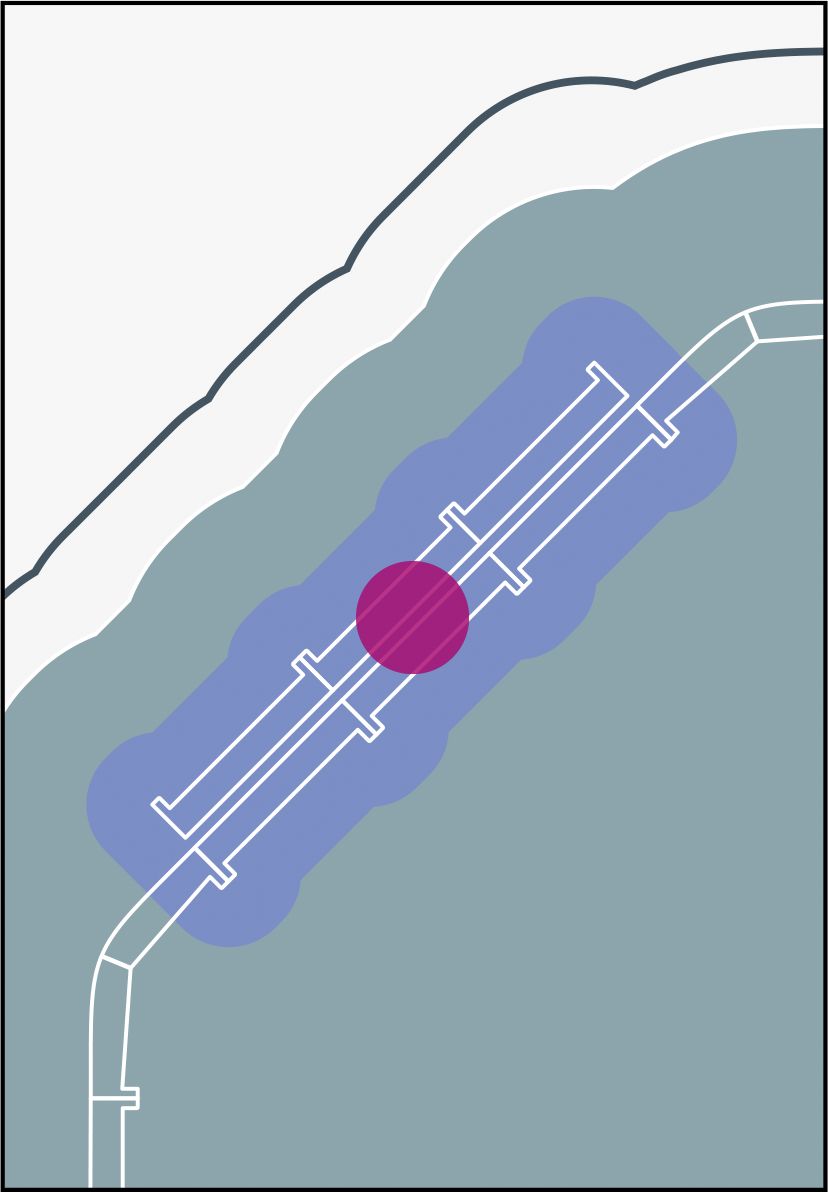

The most fine-grained analysis occurs at the micro level, where the focus is on individual shuttles. This helps to identify the exact cause of the problem, such as a laser that fires too slowly. This extremely precise analysis is perfect for implementing predictive maintenance measures. If a fill valve is not achieving the throughput that it should be, this can be an early indication of an impending fault. By detecting and correcting issues before they become critical, you can prevent downtime and significantly increase plant availability.

- Highlights

- Custom diagnostics for each operator

- Significantly higher plant availability

- Minimal downtime