Descripción

Electronically coupled axes replace mechanical axis couplings. Everything from simple coupling gears to cam applications can be implemented using mapp Technology components compliant with PLCopen. The high-performance drive control from B&R ensures that coupled movement sequences are performed accurately.

- Linear couplings with gear ratio

- Dynamic phase shifting

- Electronic cam profiles

- Compensation mechanisms

- Configuring and using Cam Profile Automats

- Using mapp technology multi-axis functions

Documentos proporcionados

TM441 – Motion control: Electronic gears and cams

In addition to single-axis functions, the PLCopen standard also offers functions for the coordinated movement of multiple axes in an axis group. By implementing mapp technology, using them is made easier. Drive coupling can be carried out quickly with this.

Objectives and content

- Properties of drive coupling

- Linear coupling and dynamic phase shift

- Creating and using electronic cam profiles

- Parameterization and application of the MpAxisCoupling component

- Structure and functionality of the Cam Profile Automat

- Implementation of the Cam Profile Automat with MpAxisCamSequencer

- Overview of the different types of compensation gearing

- Exercises and examples

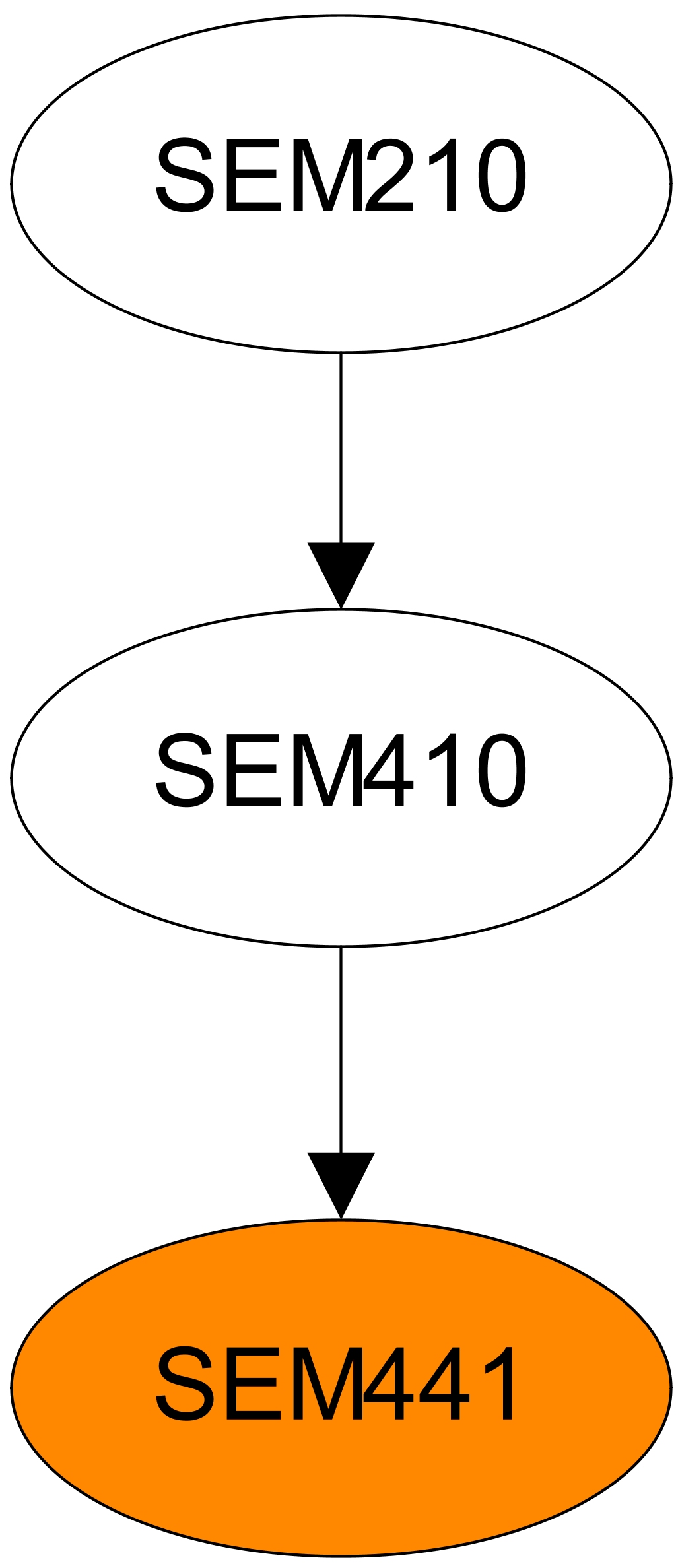

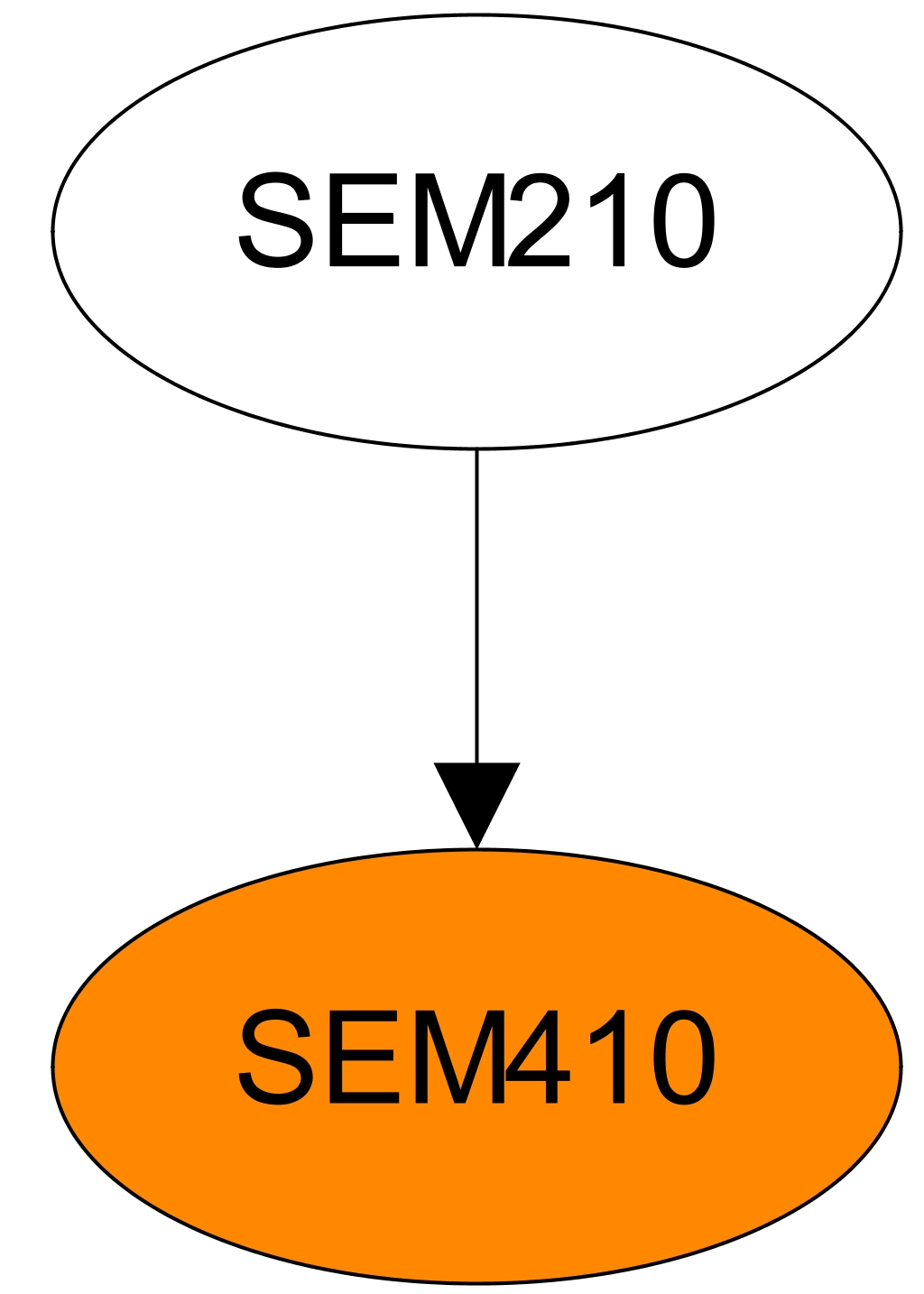

Requisitos previos

SEM210 – Automation Studio Training: Basics

Automation Studio is used to configure and program all B&R controller components. Core issues such as getting a clear overview of all product groups, initial commissioning of a controller, understanding the functions of the runtime environment and being familiar with the options for integrated configuration and diagnostics are decisive.

Learning objectives and content

- B&R company presentation

- B&R philosophy and products

- Using Automation Studio

- Using the integrated help documentation

- Establishing an online connection to the control system

- Initial installation of a controller

- Project engineering for the hardware configuration

- Working with the text and table editors

- Functions and configuration options in Automation RuntimeAutomation Runtime is the operating system that runs on all B&R controllers

- Runtime and startup behavior of the controller

- Use of the integrated diagnostics options

- Overview of available programming languages

Documents provided

|

SEM410 – Automation Studio Training: Integrated Motion Control

B&R drive solutions are configured, put into operation and diagnosed in Automation Studio. Uniform software interfaces compliant with PLCopen make it easy to program and combine a variety of different drive components in the machine.

- The components of a mechatronic drive solution

- Configuring the B&R drive solution

- The testing environment for commissioning a drive

- Using diagnostic tools

- mapp technology concept

- PLCopen-compliant basic functionsPLCopen is a vendor-independent organization in the field of industrial control technology. They develop standards intended to increase the efficiency of application development and lower the maintenance costs of associated software. (Source: translated from the German version of the PLCopen entry in Wikipedia)

- Structured programming of axis movements

- Simulation options

- Creating a sample application

- Control concept, settings and autotuning

Número de modelo

SEM441.2

Registrarse ahora Para información sobre los precios, póngase en contacto con su comercial

Lugar del evento

B&R HQ: Shanghai / 上海

No. 487 Tianlin Road, Xuhui D.

200233 Shanghai / 上海

China

Organizador

B&R HQ: Shanghai

No. 487 Tianlin Road

200233 Shanghai

China

Teléfono:

+86 / 21 54644800

Información adicional

Desde: 13.11.2024

Empezar: 09:00

Hasta: 14.11.2024

Fin: 15:00

Estado de la reserva:

Duración:

2 Días

Idioma: Chino