Test benches for commercial vehicles have to cover a very wide range of different scenarios. Traditionally, preparing for each new test has involved a considerable amount of mechanical setup and additional programming. Together with B&R, enders has developed a solution that allows the testing equipment to adapt flexibly to new test scenarios – without any rewiring or reprogramming.

The company F. X. Meiller subjects its famous dump truck solutions to a broad spectrum of quality assurance tests – from small-scale material testing to comprehensive load testing on completed dump truck assemblies.

Recently, Meiller commissioned enders to develop a flexible new test bench control system to replace an existing one that was getting on in years. For one thing, the sensors, valve actuators and other outputs had to be rewired for each new test. For another, the controller could only store one test sequence at a time. Every time they wanted to change the test sequence, they had to reload the data onto the controller.

Furthermore, it wasn't possible to create new test sequences during operation, because that required direct access to the control program. Measurement data had to be recorded using an external device. The old control system also didn't provide any opportunity for remote monitoring or maintenance of the testing process.

In an emergency, the test bench could be shut down by hitting the emergency stop or triggered by basic threshold value monitoring – but there was no way to monitor and interpret complex correlations between measurement results.

- Weaknesses of the replaced test bench:

- Mechanical setup for each new test

- No storage of multiple test sequences on the PLC

- Needed to interrupt testing to access application

- No internal storage of measurements

- No remote monitoring of test processes

Adapt test sequences flexibly

To develop the new test bench controller, enders relied on longtime partner B&R. "For us, B&R was the clear choice because the solution had to be as flexible as possible," explains Riccardo Princiotto, head of predevelopment at enders. "And with the modular software components from mapp Technology, we were able to do just that."

mapp Technology saves application developers a lot of programming work by providing many frequently required functions as pre-programmed modular components. Rather than coding from scratch, they configure the functions with only a few mouse clicks.

"Of all the options in B&R's toolbox, the mapp Sequence component was particularly helpful for our test bench application," says Princiotto. mapp Sequence made it easy for enders to embed the functionality of a configurable step sequencer or dynamic state machine seamlessly into the test bench software. Test engineers can open and modify an existing sequence in an editor or create a new one from scratch – all without any programming knowledge.

Since they can work in the editor offline on a laptop or PC, there's no need to interrupt ongoing testing to create new sequences. New sequences can be created right on the HMI screen or offline on a PC – or they can be provided along with the finished test bench in a custom sequence file.

"Test engineers can use mapp Sequence to create custom test sequences at any time, or load and modify existing ones," says Princiotto. "That makes it super easy for them to adapt the test bench to new scenarios, without needing to know anything about PLC programming." As a result, Meiller can move much more quickly from one test to the next, and handle test sequences of any complexity. "mapp Sequence is the perfect tool any time you're creating an automation solution that needs to be easily adapted to individual requirements," Princiotto adds.

- Advantages of test bench with mapp Sequence:

- No programming knowledge required

- Fast and easy switching between tests

- Offline programming for uninterrupted testing

- Recording of relevant data and measurements

- Remote access with defined user profiles

New test scenarios with no programming

Each test scenario is configured as a sequence of steps to be executed in a defined order. Creating them could hardly be easier. For each step, the operator defines one or more actions – or commands – along with the conditions under which they are to be executed.

"Operators can also define when a sequence should be aborted," notes Princiotto. "For example when the oil temperature exceeds a defined value." The operator defines the steps for each sequence and saves them on the controller for later use. In Meiller's case, around 30 sequences with an average of ten steps each were prepared for use in the test bench.

Fast results

Before starting a test sequence, the software checks whether all the specified signal sources, including the emergency stop, are connected. Since it's not always feasible to know the exact abort conditions for each signal in advance, enders has integrated a teaching function. During an initial test run, this function evaluates and displays complex correlations.

Based on this information, upper and lower limits can be defined for each signal value, which can then be used as abort criteria for the test sequence. These limits are monitored constantly during the testing process and displayed live along with the signal curves.

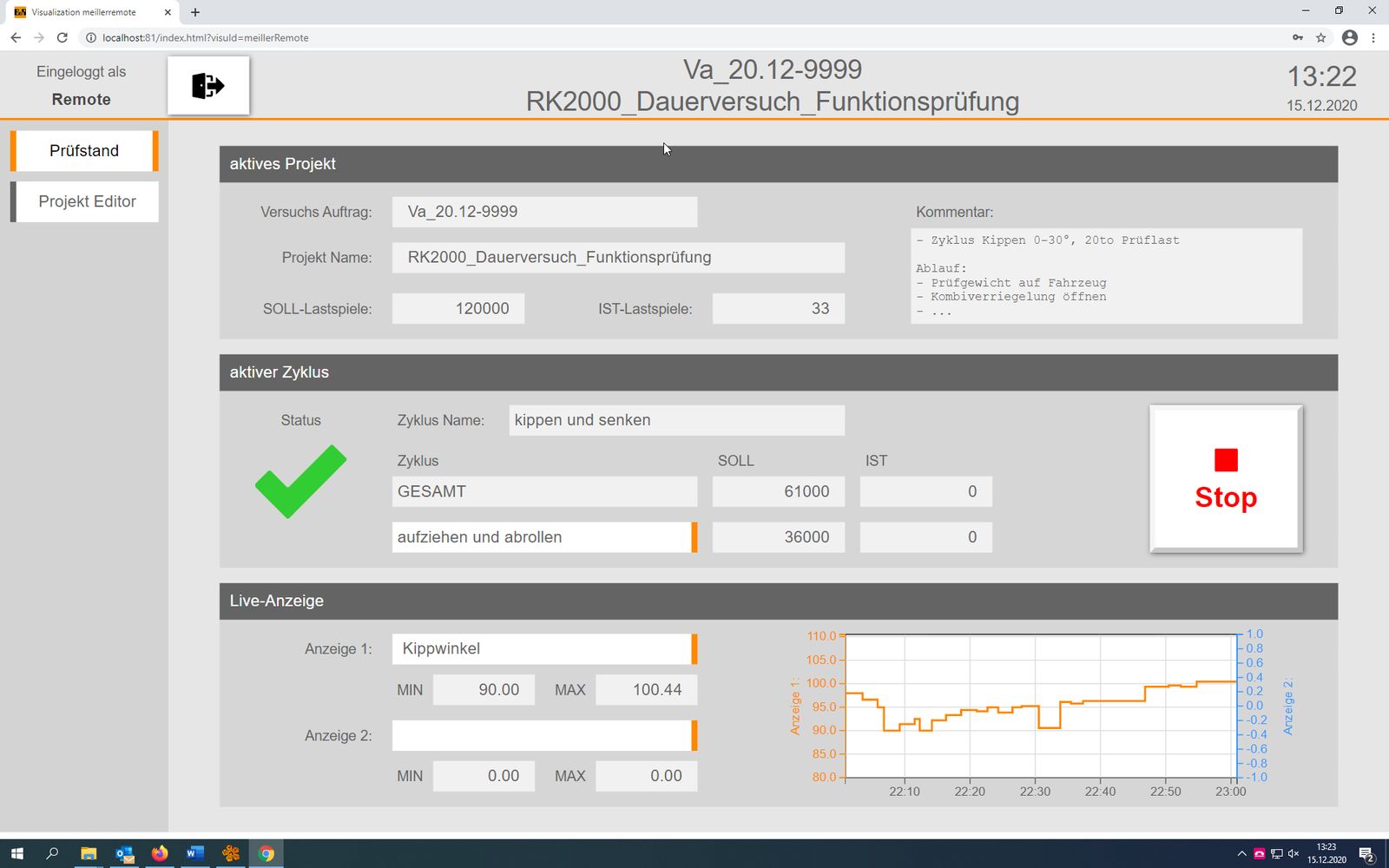

Teaching is performed using the controller's web-based user interface, which enders created using the configurable widgets of B&R's mapp View HMI solution. mapp View makes it easy to create powerful, intuitive user interfaces without having to deal with the underlying web technology.

This technology is encapsulated in widgets, which are simply dragged and dropped into place and configured. "The mapp components and widgets noticeably reduce the time it takes to program basic machine functions and HMI software," Princiotto explains. "It really makes a substantial difference, even in a relatively small project like a test bench controller."

No rewiring

The control hardware for the test bench is housed in a compact, wheeled frame. The control application runs on a PLC from the X20 system, while the HMI application is displayed on a Power Panel T80 terminal with a 10.1" multi-touch display and robust glass screen.

A variety of X20 I/O modules are used to acquire signals and control actuators. The digital and analog inputs and outputs are internally hardwired and accessible via connectors on the rear of the test bench controller. Thanks to optimized wiring and sophisticated sensor technology, the internal wiring doesn't need to be adapted for different test scenarios.

Maintenance from a distance

The previous test bench solution lacked access to important data for analysis and diagnostics. With the B&R controller, all the data is now recorded and stored for later evaluation. Different profiles and roles can be defined to manage user access. One such profile is set up specifically for remote access and unlocks a corresponding overview in the user interface.

All the relevant information about the testing process is collected by the X20 controller and displayed for the user in the HMI application. If problems occur in the field, the test sequence can also be terminated remotely.

New test sequences can be created and loaded onto the controller at any time, where they are immediately available for use on site. "B&R's mapp Technology and control hardware made the task of implementing the test bench control system exceptionally efficient," says Princiotto with satisfaction.

Author: Franz Rossmann, technology journalist from near Munich

| Riccardo Princiotto Head of pre-development, enders GmbH "B&R's mapp Technology and control hardware made the task of implementing the test bench control system exceptionally efficient." |

enders GmbH supports companies in the development of technical products, plants, manufacturing processes, complete vehicles and digitalization. The company's customers come from the fields of plant and process technology, construction machinery and special-purpose vehicles, agricultural technology, additive manufacturing, health care, commercial vehicles and automotive sectors for B2B and B2C markets. As a B&R Qualified Partner, enders has many years of experience with B&R as its preferred technology for the automation of manufacturing systems, mobile machinery and test benches. |