The demands placed on commercial vehicles have evolved dramatically over the years. With new functions being added all the time and requirements for operating efficiency and quality higher than ever, these vehicles need an automation system that is both powerful and scalable. B&R makes it easier than ever to implement automation solutions for construction equipment and municipal vehicles as well as for agriculture and forestry applications. »Download brochure.

HARDWARE

Data exchange with Automation PC Mobile

Our report on the topic of autonomous machines examines the growing role that self-driving machines are playing in boosting agricultural productivity. For autonomous equipment to perform its tasks autonomously, it needs data from a variety of sensors. The Automation PC for outdoor use can collect large amounts of data from multiple agricultural machines and forward it to higher-level systems.

A tractor and combine, for example, can share information about their respective speeds and load capacities. When agricultural machines are able to exchange information, they become more effective in the field.

Harsh conditions, reliable operation

Agricultural work is synonymous with rain, dirt, heat and vibrations. Yet even under these adverse conditions, it's crucial that operator panels ensure reliable operation. A die-cast aluminum housing provides mechanical stability, and the multi-touch display can be used even in the rain.

Modular X90 control and I/O system

Manufacturers of agricultural and construction machinery face the challenge of implementing intelligent (semi)autonomous machine functions quickly and maintaining them long term. B&R continues to open up new possibilities in the automation of mobile machinery with its modular X90 control and I/O system. The system’s comprehensive set of standardized components is perfect for implementing flexible automation concepts.

Flexible means they are able to choose controllers from a range of performance classes – ensuring consistent solutions for basic to high-end machines.

A variety of option boards for the X90 makes it easy to connect sensors, transmit diagnostics data or control stepper motors directly.

Safety for mobile machines

The European Machinery Directive and the topic of safety in general are increasingly relevant for manufacturers of mobile machinery. A risk chart like the one shown in our report on safety for mobile machinery is an important tool for analyzing risk and determining the level of safety technology required. To avoid the added cost of developing safety solutions in-house, many of them seek assistance from a reliable technology partner.

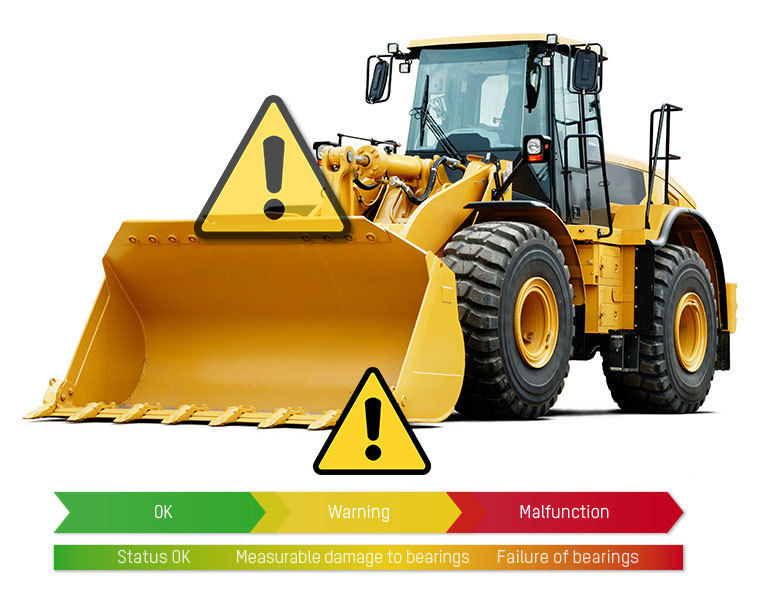

24/7 machine availability

As we all know, unscheduled downtime can be seriously costly. Our report on predictive maintenance takes a look at how these costs can be kept to a minimum with state-of-the-art analytics and maintenance. B&R's options board for condition monitoring utilizes vibration data to detect damage early, so it can be repaired before it causes equipment failure.

Software stacks for special functions

B&R offers a certified ISOBUS stack and corresponding toolchain for connecting tractors and implements. ISOBUS is a CAN-based communication protocol that enables machines from different manufacturers to exchange data. The ISOBUS stack from B&R covers all the relevant aspects of the ISOBUS standard.

- Highlights

- Vendor-independent communication between agricultural machines

- Simulation tools for efficient project development

- Certified hardware

SOFTWARE

Develop software 3 times faster with modular components

mapp Technology is revolutionizing the development of application software in the field of automation. Modular software components simplify the development of new programs and accelerate the development time for machine software by a factor of three.

How is that done? mapp streamlines implementation of programming tasks that recur frequently in the automation of mobile machinery. It does this by providing thoroughly tested, ready-made software components. Programmers can then concentrate on their main task: Implementing automation processes in the application software.

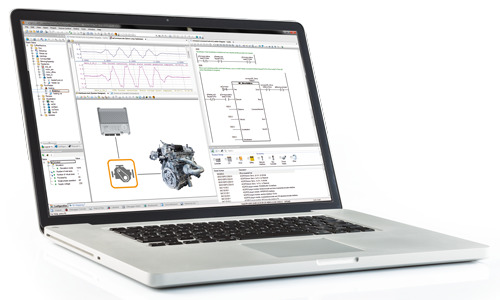

A universal engineering tool for all tasks

Automation Studio is B&R's integrated software development environment with tools for all phases of a project. Controllers, drives, communication equipment and HMI devices can all be configured in one environment. That reduces both integration time and maintenance costs when developing new construction machinery. Automation Studio allows PLC programming in all IEC 61131-3 languages, in CFC and C, as well as object-oriented programming in C++.

Simulation saves time and boosts quality

Each developer can work in their preferred language and mobile machines can be developed faster and easier. Tests on real agricultural machinery are costly and time consuming. With machinery growing more complex by the day, the topic of modeling and simulation is rapidly gaining significance. B&R offers the tools you need with MATLAB/Simulink and MapleSim.

ONE PARTNER – ONE SOLUTION

Perfection in Automation means more to us than developing the best solutions in mobile and industrial automation – it also means developing lasting relationships with our customers, partners, employees and suppliers based on mutual trust and measurable benefits. With over 180 offices worldwide , B&R is never far away.

Contact us

AgroIntelli's Robotti is an innovative agricultural robot for use in the field. It was important for them to have a technology partner at their side who understands the entire development process including both hardware and software. A partner who offers the infrastructure to think in global dimensions.

The sewer cleaning vehicle of Aryan Pumps recycles extracted sewage water in order to use it again the next time a sewer is cleaned. For a task like this, it's clearly advantageous to have a rugged control system. B&R software made it easy to program using standard IEC 61131 languages.

Highlights of automated Benzberg trailers include automatic steering and a hydrostatic transmission. Automatic slope compensation adjusts the trailer bed horizontally to prevent payload from being lost.