Short product lifecycles and an unbroken trend towards individualization are increasingly pushing conventional assembly and production machines to their limits. The matter is further complicated by the need to accommodate new packaging types and materials. With its new machine, German packaging machine builder Wolf shows how B&R technology can move products through the line with unprecedented flexibility and gentle handling.

"Major retail chains and global players in the packaging industry are aiming to complete the transition to environmentally friendly packaging within the next few years," says Markus Schmachtel, head of design and engineering at Wolf. Since it was founded in 1988, Wolf has delivered more than 3,000 filling and packaging machines, making quite a name for itself especially in the food industry. Looking back on his equally long career in packaging technology, Schmachtel is able to recall many upheavals along the way. "Typically, a design engineer will try solve new requirements with a mechanical approach. As the variety of packaging types and materials continues to grow, however, packaging machines need transport solutions that are substantially more flexible and gentle on the product than the purely mechanical chain driven conveyors that have been prevalent thus far.

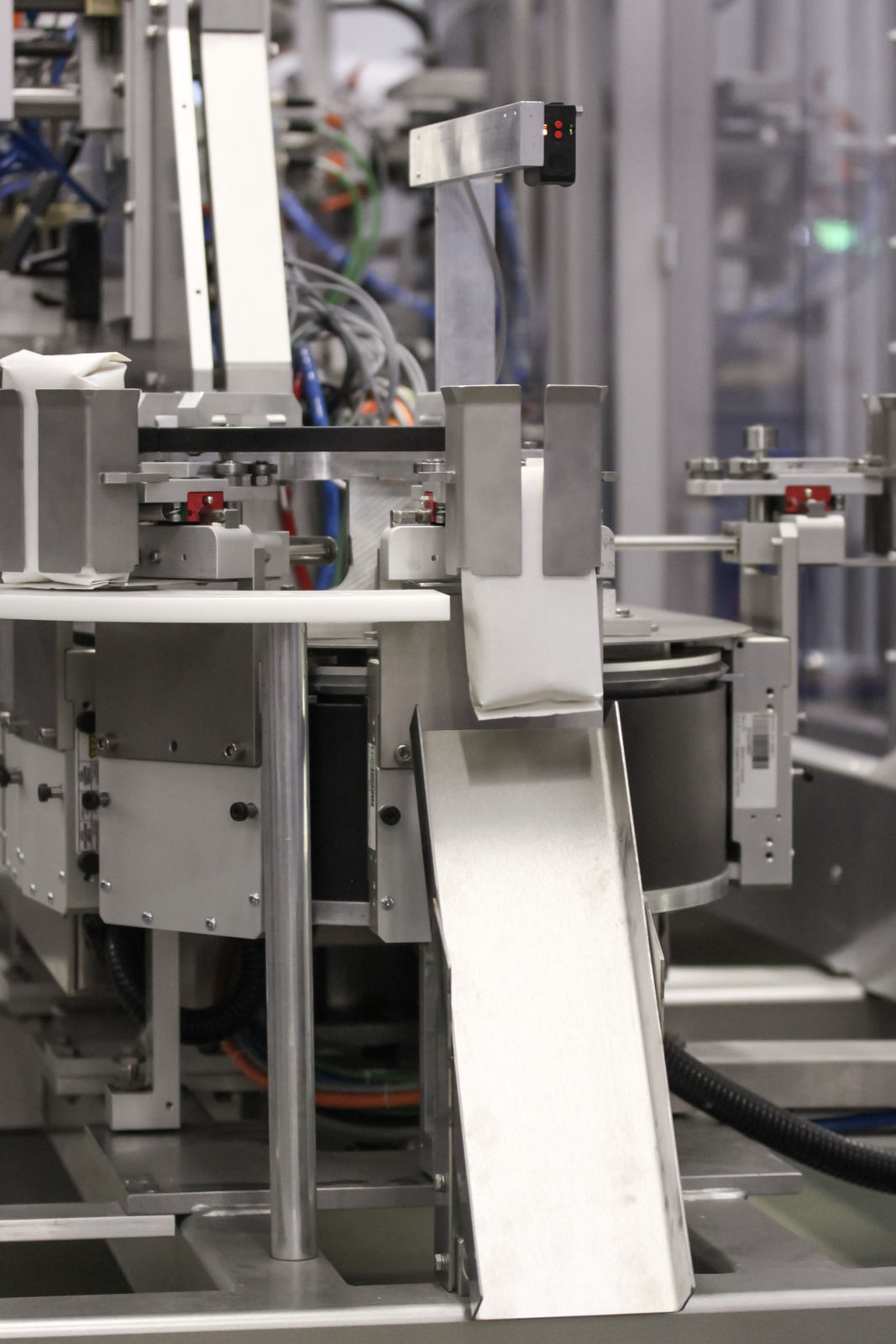

Wolf offers a vertical form fill seal (FFS) machine with easy changeover between all commonly used bag types, including flat or gusseted bags as well stand-up bags with sealed edges. Until now, a top closing machine connected to the FFS machine has transported the products using coupled chains, which feature pusher dog attachments that form compartments for the bags. With this design, the bags are pushed along in a standing position together with the entire transport mechanism, all synchronized with the timing of the FFS machine. As the bags move, the bottom glides over the base plate of the transport system.

Gentle transport of sensitive eco-packaging

For a combination of marketing and environmental reasons, paper is gaining in popularity as a packaging material. Especially at higher transport speeds, however, the bottoms of paper bags could be subjected to too much strain, or the bags themselves could become deformed due to shearing forces. Coarse and stiff paper types are particularly susceptible to these problems. "You can minimize the problem with the bags deforming by putting a special coating on the affected surfaces," explains Schmachtel. "But that wears off over time and contaminates the production environment. An increasing number of companies are even banning such coatings from their production halls, so our customers are sure to appreciate a product transport solution that is virtually wear-free."

To be prepared for the challenges that lie ahead, Wolf decided to develop a new top closing machine. A variety of decoupled transport systems were tested with regard to payload, shuttle handling and supplier support. B&R's long-stator linear motor based SuperTrak system – specially designed for the higher performance range – prevailed in the end.

In combination with one or two FFS machines and a corresponding dosing unit – the goal for the single variant of the top closing machine was to be capable of producing, filling and sealing up to 80 bags per minute. For the duplex variant, the goal was up to 130 bags per minute.

Changeover with minimal effort

A further goal was for the machine to be able to handle a wide range of bag types, materials and closure methods with as little effort as possible for changeover. This would enable plant operators to react flexibly to market requirements and to choose from a variety of closure variants such as label closure, gable closure, rider top or clip closure.

In order to do this, the bags that have been formed, filled and sealed by the FFS machine must be handed off to the transport system of the top closing machine, which takes them to the various processing stations. In the case of a block bottom bag with label closure, these stations would form the top, press it, cut it, seal it and fold it over to make a compact bag without any unnecessary space at the top. Finally, the folded top is attached to the block-shaped bag with a label.

Independent shuttles for maximum flexibility

Unlike a chain driven conveyor with fixed coupling, the SuperTrak system transports the bags in cartridges mounted on independently controlled shuttles. This allows the shuttles to pass through the processing stations of the top closing machine independently of the rate they leave the FFS machine.

"Since the bags are carried through the machine in the cartridges, there are no shearing forces on the bottom of the bag," explains Schmachtel. "Each shuttle can be programmed and controlled individually. This enables us to tailor the movement profiles to different packaging types and contents, which allows us to produce more efficiently and gently than ever before."

The shuttles can also travel backwards. Wolf's designers used this option to incorporate a vibratory movement into the movement profile of the top closing machine. "This eliminates the need for a separate station that vibrates the bags in order to compress bulk material. The space that is saved can be put to other use. The vibration process no longer has to be completed within a certain timeframe, so it can be implemented more gently and/or more effectively. Users can also implement different movement profiles with custom vibration functions for different product variants.

Increased output

Thanks to the freely programmable movement profiles, designers have more freedom in how to arrange the processing stations, and can skip or add stations as necessary. One way to take advantage of this is to double up time-critical stations in order to boost output or hit a target cycle time. You can do this without needing to have two of every other station as well, as you would with a fixed chain conveyor system.

The programmable movement profiles also make it possible to process multiple packaging types or materials on the same line with minimal added effort, simply by of adding or skipping processing steps for certain bags. This makes the SuperTrak-based top closing machine the ideal counterpart to Wolf's flexible FFS machine:

"SuperTrak makes it possible to boost output or produce product variants with minimal added costs," adds Schmachtel. "It also makes it easier to integrate into the user's production line, and the customizable movement profiles give us more freedom with regard to where we position the transfer stations for the FFS machine or packer. The entire system layout is really easy to adapt to the situation on site." The modular design of the guide rails of the high-speed SuperTrak system gives the machine builder additional degrees of freedom in designing the machine layout. "We can easily lengthen or shorten the top closing machine and adjust the number of shuttles as required," says Schmachtel. "The flexibility to change the overall direction of movement makes it easy to adapt to new requirements."

System layout with many degrees of freedom

In the first new-generation machine built by Wolf, a simple SuperTrak oval, consisting of two 180° curved segments and six straight segments, each one meter long, was sufficient to meet the specifications. This is in large part because SuperTrak's curved segments can also be used for processing. Wolf even planned in sufficient space reserves to accommodate additional stations in the future – even in later phases of the system's lifecycle.

"B&R's simulator tool allowed us to check in advance whether the current design and any future expansions would be able to meet the target cycle time. We were able identify just the right number of shuttles and parallel processing stations to handle a respective bag type. That way we can avoid unnecessary investments and minimize development risks," reasons Schmachtel. The high power efficiency of the system also reduces operator costs. With the SuperTrak solution, the only thing that needs to be moved are the shuttles and bag cartridges. That's considerably less mass than with a permanently coupled transport system, which means less power is needed for acceleration and braking. Braking energy is also recovered and used to accelerate the shuttles.

Fertile ground for innovations

The potential of the new transport solution is far from exhausted and gives Wolf room for future innovations, as Schmachtel is pleased to point out: "We have only begun to explore the possibilities of SuperTrak. It would be possible, for example, to have two shuttles grip a bag and open it as it travels between stations or to combine shuttles for an increased payload. Things like that open up exciting new possibilities to design groundbreaking new filling and packaging machines."

Author: Franz Rossmann, technology journalist from near Munich

| Markus Schmachtel Head of Design and Engineering, Wolf "Each shuttle can be programmed and controlled individually. This enables us to tailor the movement profiles to different packaging types and contents, which allows us to produce more efficiently and gently than ever before." |

SuperTrak

SuperTrak has been specially developed for 24/7 operation in harsh industrial environments. It is reliable, safe and supports very high payloads. SuperTrak also optimizes changeover times when manufacturing multiple products on the same line. As soon as the operator chooses a different option, the transport system automatically adapts the flow of products. The shuttles can be replaced easily without having to disassemble the track. This results in a very low mean repair time and increases the productivity of the entire plant.